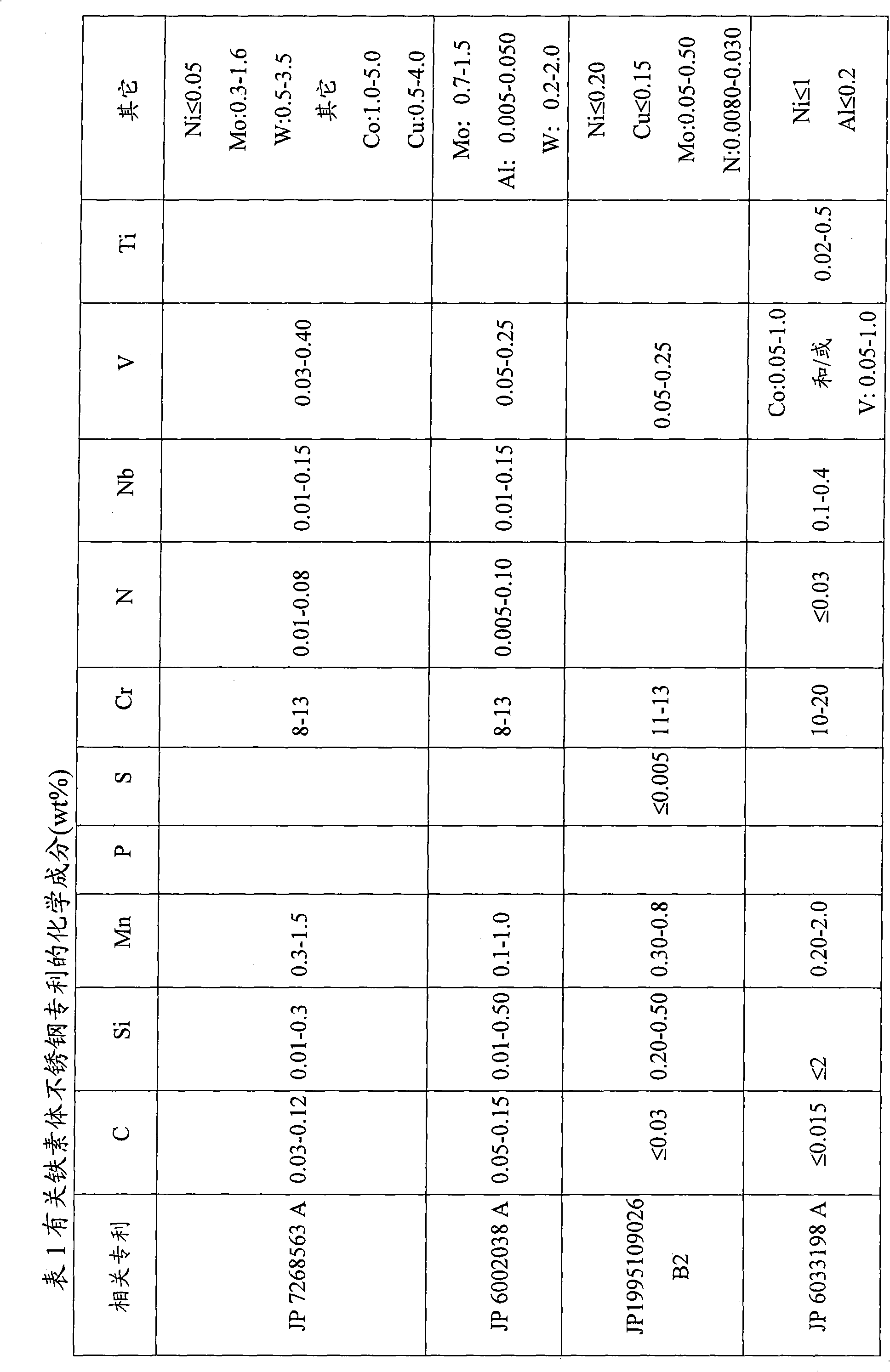

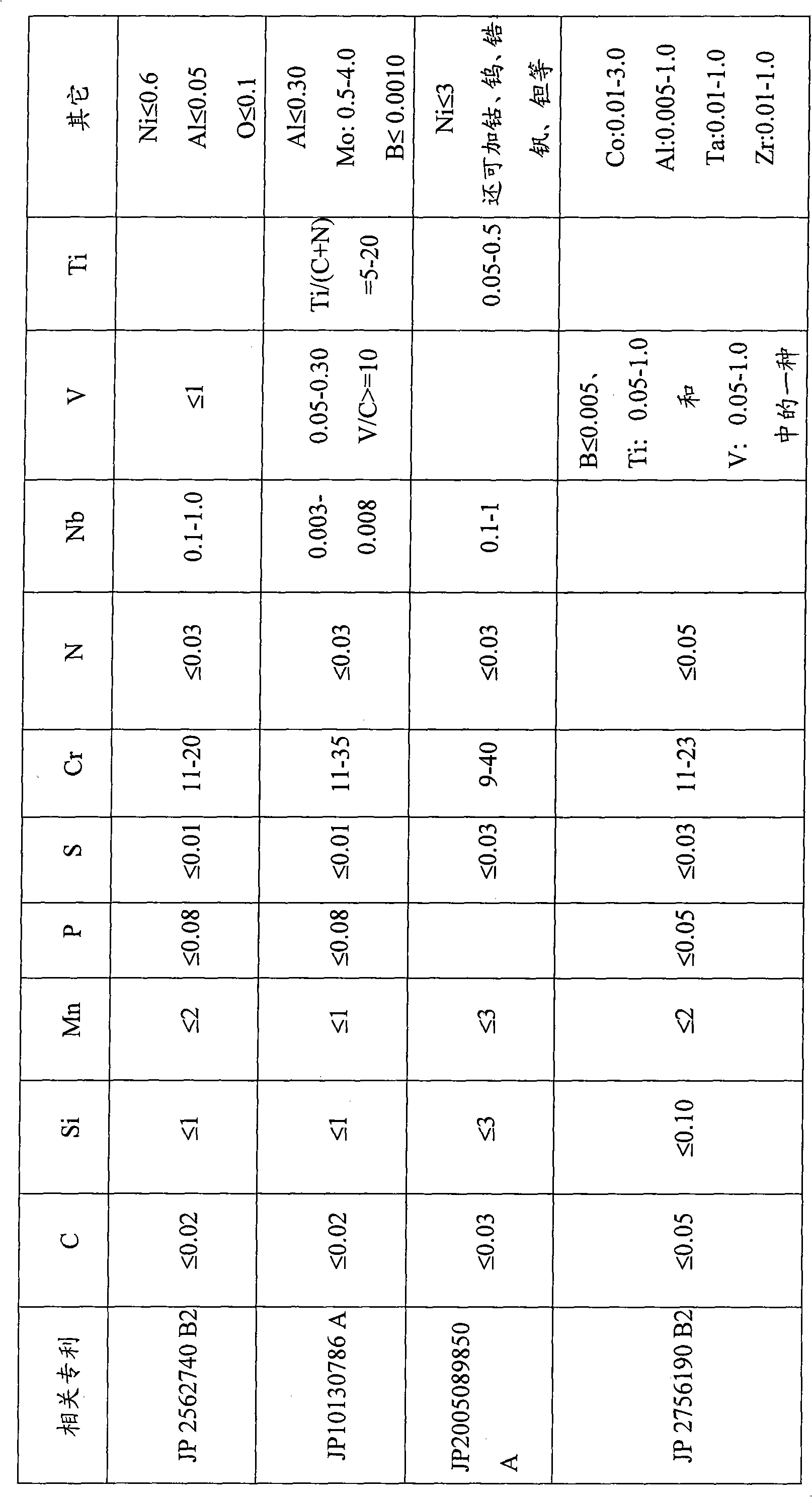

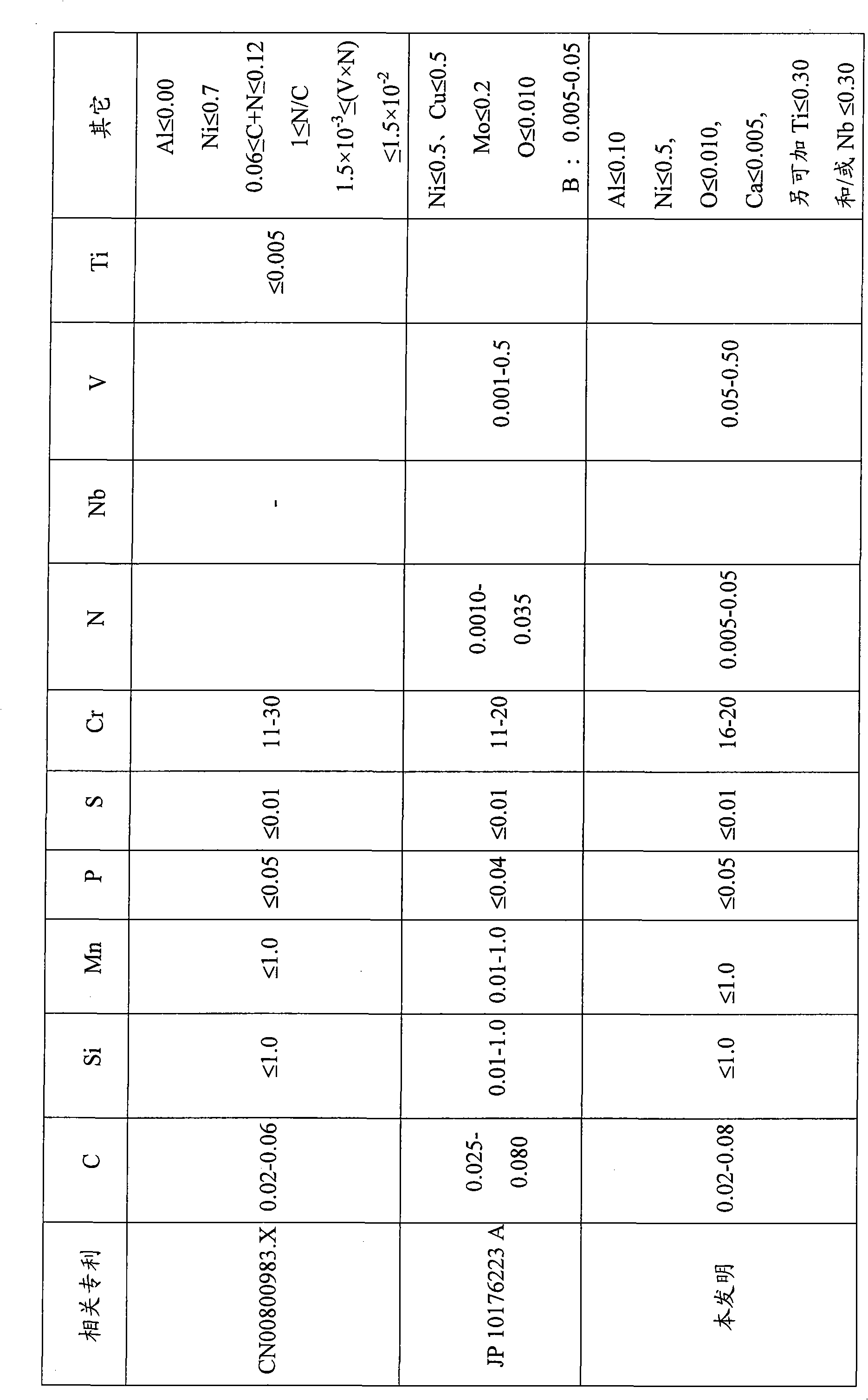

Medium chromium ferrite stainless steel and making method thereof

A stainless steel, element body technology, applied in the direction of temperature control, rolling force/roll gap control, etc., can solve the problems of low strength and hardness, poor formability, etc., and achieve the effect of good strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Ti: 0.12 is added to the chemical composition.

[0041] The method is as follows: the heating temperature of steel slab or continuous casting slab is 1250°C; hot rolling, the final rolling temperature is 900°C, and the coiling temperature is 750°C; hot rolling annealing: 900°C×6min.

Embodiment 1-1

[0043] Chemical composition is with embodiment 1.

[0044] The method is the same as in Example 1, and additional steps are included: cold rolling: two rolling passes, cold rolling reduction rate 45%+60%; intermediate annealing: 950°C×6min; final annealing: 950°C×6min.

Embodiment 1-2

[0046] Chemical composition is with embodiment 1.

[0047]The method is as follows: billet or continuous casting billet heating temperature is 1000°C; hot rolling, final rolling temperature is 800°C, coiling temperature is 750°C; hot rolling annealing: 900°C×6min; cold rolling: two rolling passes, cold rolling The lower rate is 45%+60%; intermediate annealing: 950℃×6min; final annealing: 750℃×10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com