Saline-alkali tolerant polymer modified asphalt, waterproof roll material and preparation method of waterproof roll material

A polymer, saline-alkali-resistant technology, used in water conservancy projects, building structures, building insulation materials, etc., can solve the problems of short service life of waterproof membranes, and achieve strong resistance to pressure water, excellent high and low temperature resistance, The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

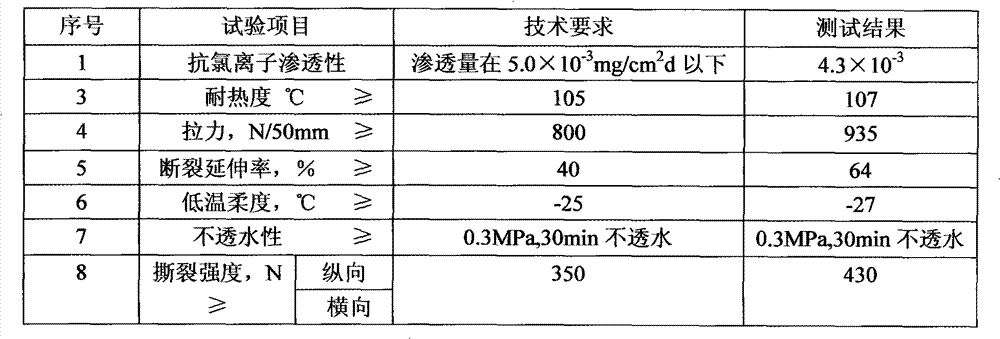

[0027] The ratio by mass percentage is as follows: asphalt 100, saline-alkali-resistant modifier 20, polymer modifier 20, and the accurately weighed asphalt, polymer modifier, saline-alkaline modifier Stir the agent to achieve macroscopic uniformity. After the membrane forming process, the salt-resistant and alkaline polymer modified bitumen waterproof membrane is tested according to the national standard GB18242-2000 "Elastomer Modified Bitumen Waterproof Membrane", and it is resistant to chloride ion penetration. The performance test is carried out according to the industry standard JTJ 275-2000 "Technical Code for Anti-corrosion of Concrete Structures in Harbor Engineering". The test results are shown in Table 1.

Embodiment 2

[0029] The ratio by weight percentage is as follows: asphalt 100, salt-alkali-resistant modifier 25, polymer modifier 25, add accurately weighed asphalt, salt-alkali-resistant modifier, polymer The modifier is stirred to achieve macroscopic uniformity, and the salt-alkali-resistant polymer-modified asphalt waterproofing membrane is obtained through a membrane forming process. The performance test is carried out according to the national standard GB18242-2000 "Elastomer Modified Bituminous Waterproof Membrane". The performance test of the chloride ion permeability is carried out according to the industry standard JTJ 275-2000 "Technical Specifications for Anti-corrosion of Concrete Structures in Harbor Engineering". The test results are shown in the table 2.

Embodiment 3

[0031] The ratio by weight percentage is as follows: asphalt 100, salt and alkali resistance modifier 27, polymer modifier 18, and accurately weighed asphalt, polymer modifier, salt and alkali resistance The modifier is stirred to achieve macroscopic uniformity, and the salt-alkali-resistant polymer-modified asphalt waterproofing membrane is obtained through a membrane forming process. The performance test is carried out according to the national standard GB18242-2000 "Elastomer Modified Bitumen Waterproof Membrane", and the performance test is carried out according to the industry standard JTJ 275-2000 "Technical Specifications for Anti-corrosion of Concrete Structures of Harbor Engineering". The results are shown in Table 3.

[0032] Table 1 Test results of salt-alkali-resistant polymer modified bitumen waterproof membrane in Example 1

[0033]

[0034] Table 2 Test results of salt-alkali-resistant polymer modified bitumen waterproof membrane in Example 2

[0035]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com