Method for preparing vinyl cyanide/methacrylic acid copolymer

A technology of methacrylic acid and acrylonitrile, applied in the field of preparation of acrylonitrile/methacrylic acid copolymer, can solve the problem of difficult to become high-performance foam plastic, high polymer foam plastic with poor mechanical properties and low chain link ratio, etc. problem, to achieve the effect of low water absorption, good stability and high heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

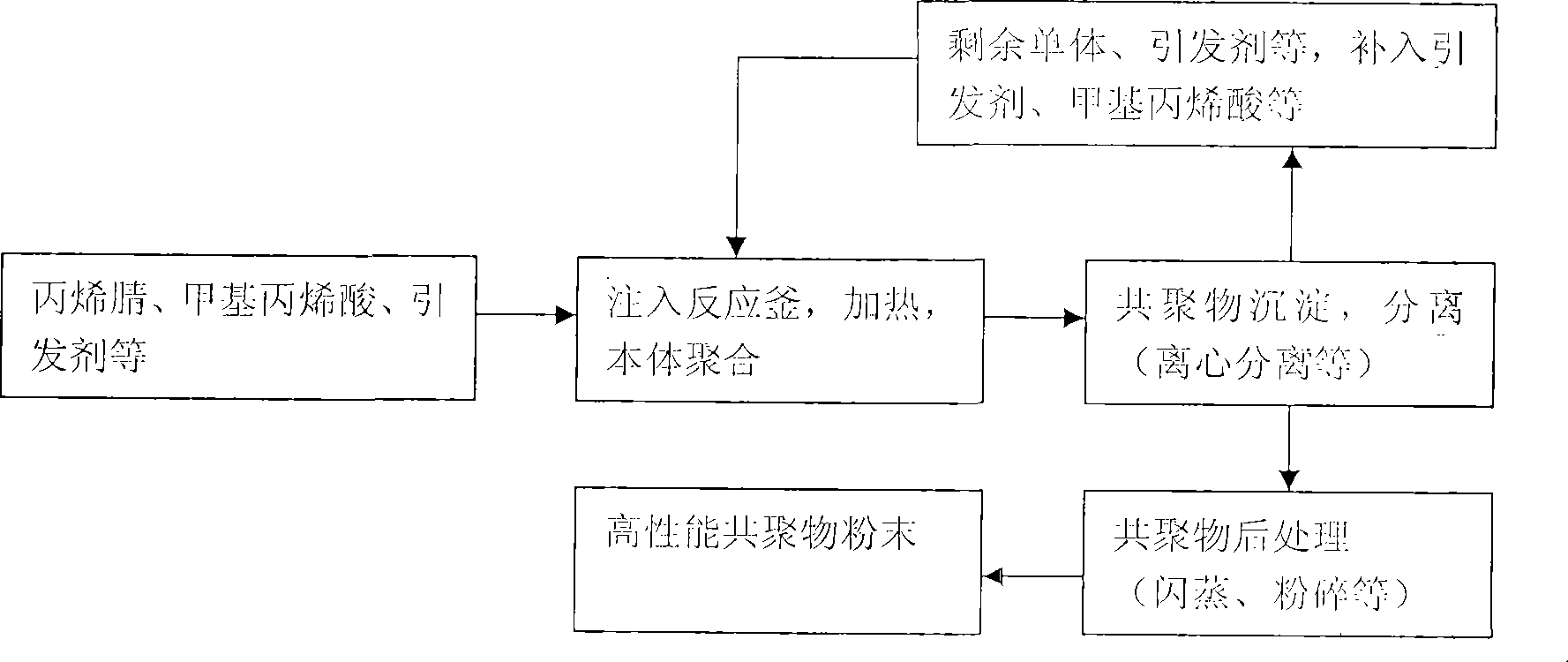

Method used

Image

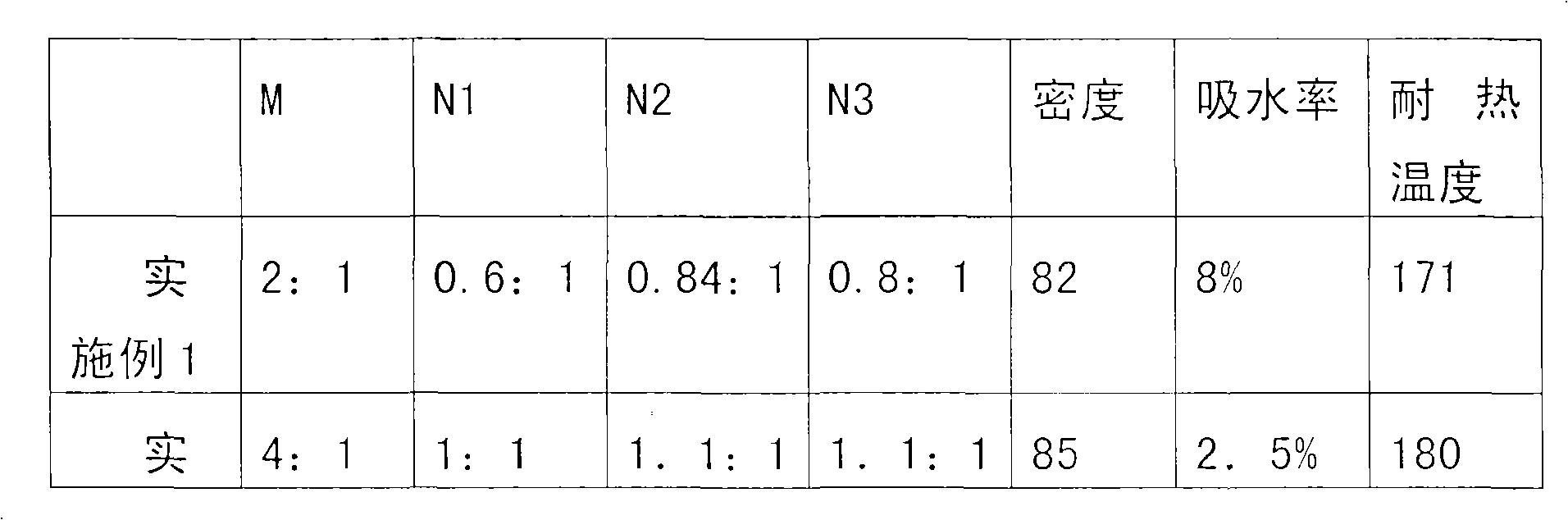

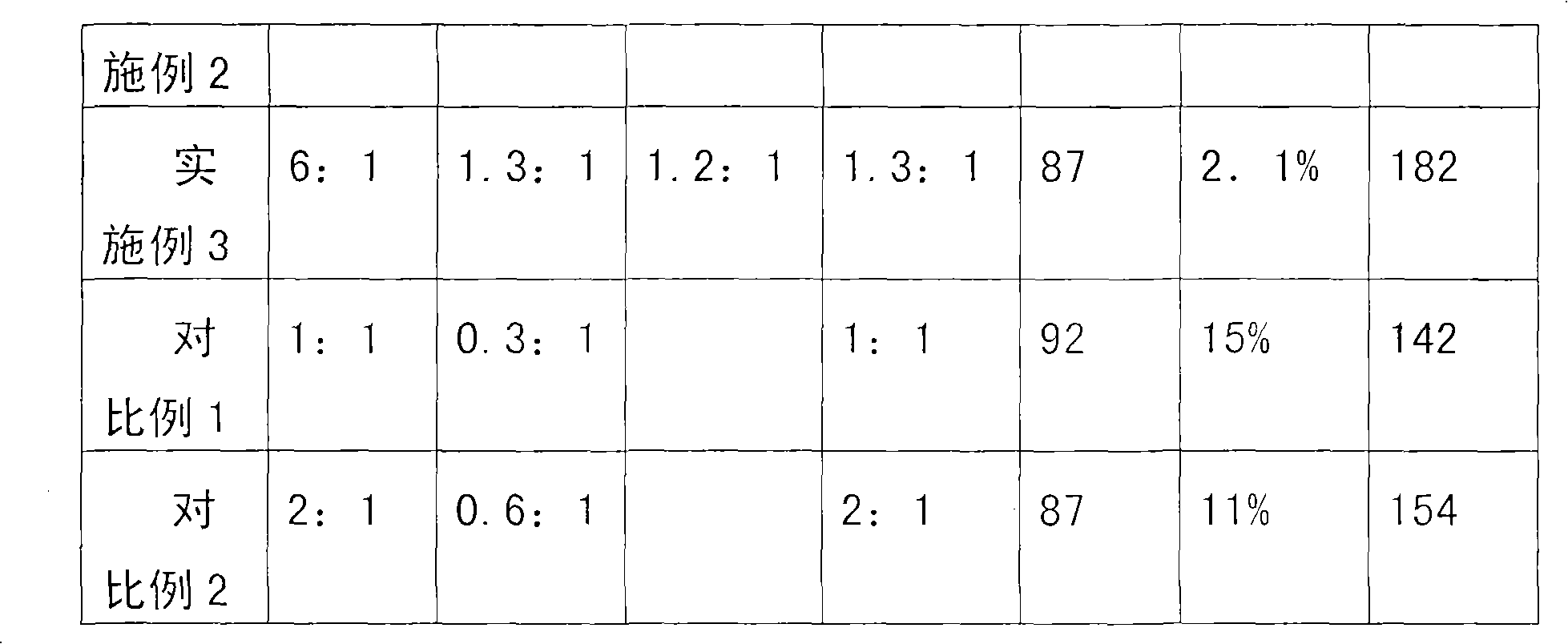

Examples

Embodiment 1

[0034] In a 5-liter reaction kettle equipped with a reflux condenser, temperature control equipment, and stirring equipment, vacuumize and inject nitrogen, and then vacuumize and inject nitrogen for three consecutive times; add 2.4 liters of acrylonitrile and 1.55 liters of methyl Acrylic acid, 3.6 grams of azobisisobutyronitrile.

[0035] Start stirring, the stirring speed is 30 rpm, the temperature of the reactor is raised to 50°C, and the polymerization reaction is started;

[0036] Half an hour after the polymerization reaction, centrifugal separation, continuous separation or intermittent separation, the separated liquid is refluxed into the reactor;

[0037] During the reaction, the mixture of methacrylic acid and initiator azobisisobutyronitrile, wherein the initiator azobisisobutyronitrile content is 0.9 grams per liter; slowly and continuously injected into the reactor by a metering pump, the injection speed is 1.5 milliliters / liter Minutes, keep the ratio of the two...

Embodiment 2

[0042]In a 5-liter reactor equipped with a reflux condenser, temperature control equipment, and stirring equipment, vacuumize, inject nitrogen, and then vacuumize, inject nitrogen; three times in a row. Add 3 liters of acrylonitrile, 0.97 liters of methacrylic acid, and 100 grams of azobisisobutyronitrile into the kettle. Start stirring at 30 rpm, and the reaction kettle is heated to 30 degrees Celsius.

[0043] Half an hour after the polymerization reaction, centrifugal separation, continuous separation or intermittent separation, the separated liquid is refluxed into the reactor;

[0044] During the reaction, 73.8 milliliters of acrylic acid, acrylonitrile and initiator azobisisobutyronitrile mixture were injected into the reactor every half hour; Content 25 g / L.

[0045] Its following operation steps are identical with embodiment one.

[0046] The solid obtained in the above steps is weighed to obtain 562 grams; during the reaction process, the following three samples ar...

Embodiment 3

[0048] In a 5-liter reactor equipped with a reflux condenser, temperature control equipment, and stirring equipment, vacuumize, inject nitrogen, and then vacuumize, inject nitrogen; three times in a row. Add 2.8 liters of acrylonitrile, 0.6 liters of methacrylic acid, and 1.42 grams of dibenzoyl peroxide into the kettle. Start stirring at 30 rpm, and the reaction kettle is heated to 60 degrees Celsius.

[0049] During the reaction process, at intervals of 30 minutes, use a horizontal scraper centrifugal separation device to separate the copolymer for 30 minutes; the separated liquid is returned to the reactor;

[0050] During the reaction, inject 30 milliliters of the mixture of methacrylic acid and initiator dibenzoyl peroxide into the reactor every 20 minutes; wherein the initiator dibenzoyl peroxide content is 0.6 g / liter; keep two single body proportions.

[0051] Its following operation steps are identical with embodiment one.

[0052] The solid obtained in the above s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com