Nickel-zinc secondary battery and preparation method thereof

A secondary battery, nickel-zinc technology, applied in the manufacture of nickel batteries, alkaline batteries, battery electrodes, etc., can solve the problems of short battery cycle life, poor negative electrode conductivity, poor slurry fluidity, etc., and achieve low cost and discharge platform. High and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 A nickel-zinc secondary battery and its preparation method

[0033] (1) Preparation of cobalt-coated β-nickel oxyhydroxide (cobalt-coated β-NiOOH)

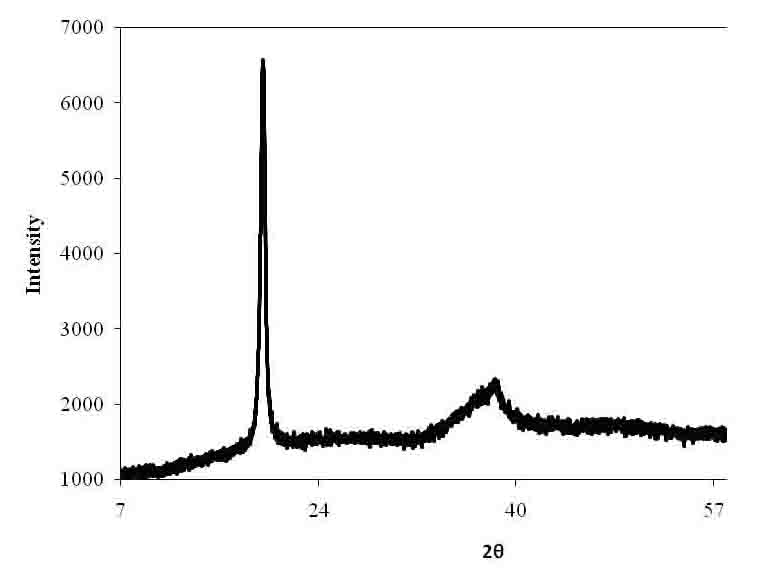

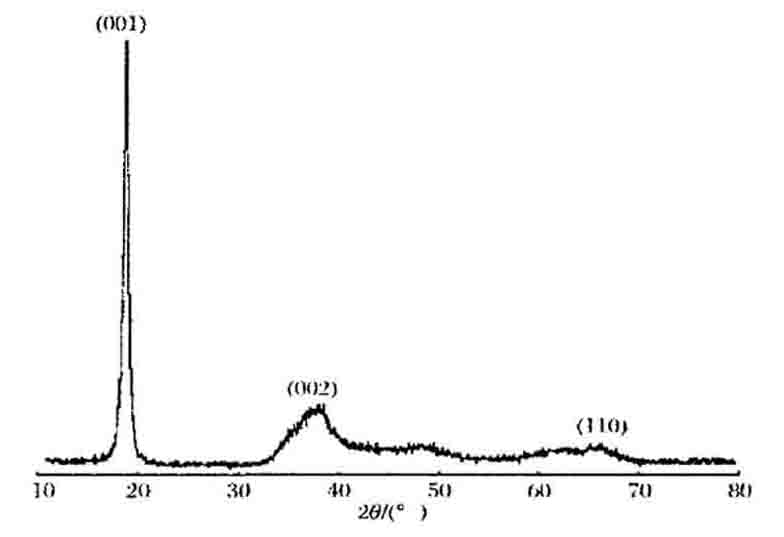

[0034] At room temperature, dissolve 800g NaOH in 2000g deionized water, add 1330g cobalt-coated Ni(OH) 2 Mix and stir, keep the temperature at 25°C, add 1670g Na 2 S 2 o 8 , raise the temperature to 60°C±5°C and keep it warm, stir rapidly for 2h, then let the reaction solution stand for 0.5h, separate layers, remove the clear liquid in the upper layer, add 2000ml of water, continue to stir for 0.5h, stand still, separate layers, remove the supernatant , add 700ml of water in three times, wash and vacuumize, and dry the precipitate at 80°C for 2h to obtain the product. The product is made XRD pattern, the result is shown in figure 1 . From Figure 1 and figure 2 It can be seen that the XRD pattern of the product is the same as that of the standard sample β-NiOOH (JCPDS 06-0141), and it is verified that the ...

Embodiment 2

[0060] Example 2 A nickel-zinc secondary battery and its preparation method

[0061] (1) Preparation of cobalt-coated β-nickel oxyhydroxide: same as in Example 1;

[0062] (2) Preparation of the positive electrode sheet: the positive electrode active material is a mixture of cobalt-coated β-NiOOH and cobalt-coated spherical nickel hydroxide in a weight ratio of 1:9, and the positive electrode active material, Y 2 o 3 Mix with HEC at 98%, 1%, 1% by weight evenly, then add water 0.2 times the weight of the mixture to prepare a slurry, and then coat it on the nickel foam, cut it into a size of 95mm×42mm×0.6mm, make into a positive plate;

[0063] (3) Preparation of the negative electrode sheet: The negative electrode active material is metal zinc powder (Zn) mixed with zinc oxide (ZnO) in a weight ratio of 1:4. The negative active material, Bi 2 o 3 , Y 2 o 3 , PEO is 97%, 1%, 1%, and 1% by weight, mix evenly, then add 0.03 times the weight of the mixture to prepare a sl...

Embodiment 3

[0072] Example 3 A nickel-zinc secondary battery and its preparation method

[0073] The preparation method is the same as in Example 1, and only the composition of the positive electrode sheet, the negative electrode sheet, the separator paper and the electrolyte is changed according to Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com