High-performance lithium ion battery electrode material and preparation method

A lithium-ion battery and electrode material technology, applied in the field of electrochemistry, can solve problems such as poor cycle life of titanium pyrophosphate electrode materials, achieve the effects of overcoming poor cycle performance, ensuring cycle performance, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] As a comparative example, a commercial-grade spinel-type LiMn was used for the positive electrode. 2 O 4 , the slurry ratio is in accordance with LiMn 2 O 4 : Conductive agent: Binder = 80:10:10 mixed slurry, and then pressed into a film with a rolling mill, and the pressed film was dried in a vacuum drying oven at a constant temperature of 100 ° C for 6 hours.

[0026] The negative electrode uses pure TiP 2 O 7 , and its synthesis method is as follows: the TiO 2 (3.45g, 30mmol) and NH 4 H 2 PO 4 (1.20g, 15mmol) were mixed and ground according to the stoichiometric ratio, then an appropriate amount of distilled water was added, and the mixture was continuously stirred at 80 ° C until the mixture was dry. Finally, the above mixture was placed in a boat-shaped crucible, and then calcined at 700 ° C in air for 6 hours to obtain TiP 2 O 7 . TiP 2 O 7 The preparation of the electrode is the same as that of the positive electrode. In this example, the actual cap...

Embodiment 2

[0028] As a comparative example, a commercial-grade spinel-type LiMn was used for the positive electrode. 2 O 4 , the slurry ratio is in accordance with LiMn 2 O 4 : Conductive agent: Binder = 80:10:10 mixed slurry, and then pressed into a film with a rolling mill, and the pressed film was dried in a vacuum drying oven at a constant temperature of 100 ° C for 6 hours.

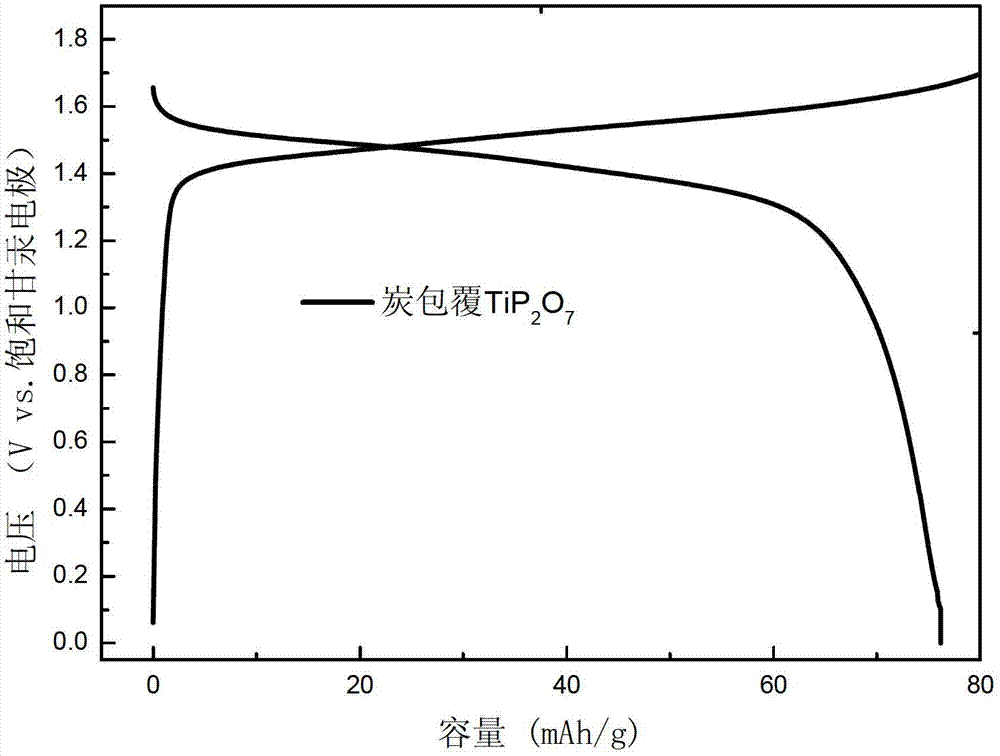

[0029] The anode uses carbon-coated TiP 2 O 7 , its synthesis method is as follows: with the TiP in Example 1 2 O 7(3.33g, 15mmol) as raw material, placed in a mortar and ground into powder, then added with a mass fraction of 0.75% sucrose aqueous solution (30mL), continuously stirred at 80 ° C until the mixture was dry, and finally the above mixture was placed in a boat crucible , and then calcined at 700 °C for 1 hour under nitrogen atmosphere to obtain carbon-coated C(2.8%)-TiP 2 O 7 . The electrode preparation is the same as that of the positive electrode. In this example, the actual capacity of t...

Embodiment 3

[0031] The positive electrode uses commercial grade spinel LiMn 2 O 4 , the slurry ratio is in accordance with LiMn 2 O 4 : Conductive agent: Binder = 80:10:10 mixed slurry, and then pressed into a film with a rolling mill, and the pressed film was dried in a vacuum drying oven at a constant temperature of 100 ° C for 6 hours.

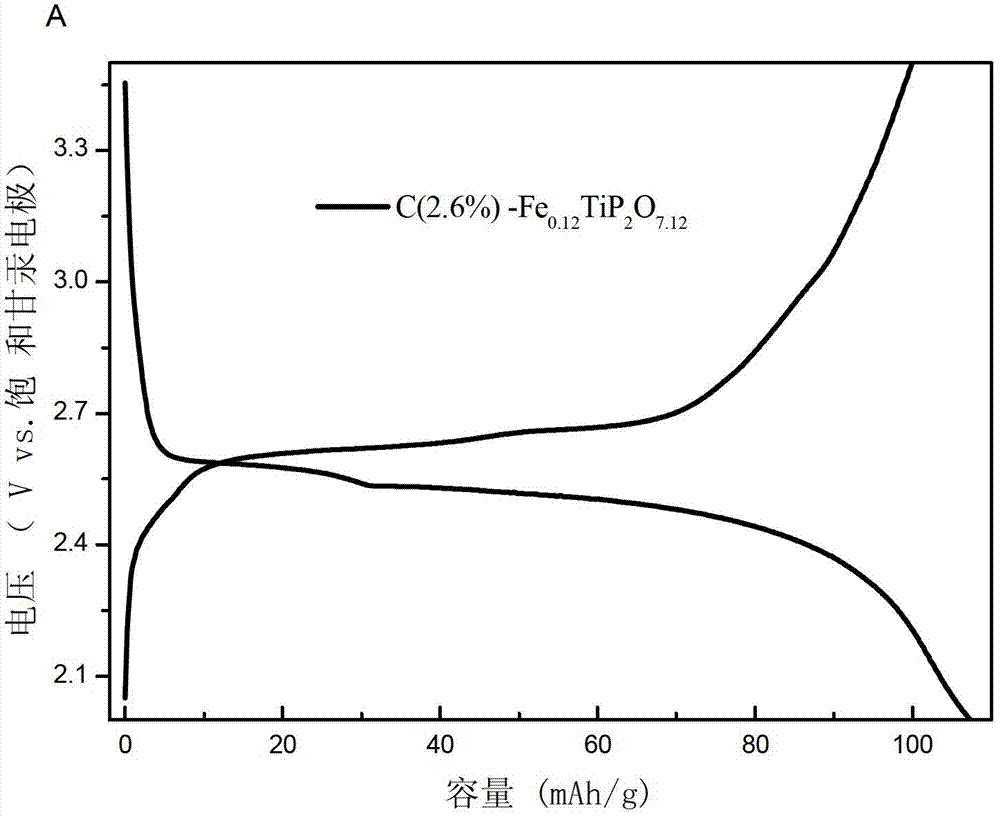

[0032] The negative electrode uses carbon-coated C-Fe x TiP 2 O 7+x , its synthesis method is as follows: with the TiP in Example 1 2 O 7 as raw material, weigh TiP 2 O 7 (3.33g, 15mmol) and FeC 2 O 4 ·2H 2 O (0.32 g, 1.8 mmol) was placed in a mortar and mixed uniformly, then a 0.75% sucrose aqueous solution (30 mL) was added, and the mixture was continuously stirred at 40 ° C until the mixture was dry. Finally, the above mixture was placed in a boat crucible, Then calcined at 700 °C for 1 hour in a nitrogen atmosphere to obtain carbon-coated C(2.6%)-Fe 0.12 TiP 2 O 7.12 . The electrode preparation is the same as that of the positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com