Preparation method of high-specific-energy fluorinated graphene lithium battery

A fluorinated graphene and graphene battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of small specific gravity and low conductivity, and achieve the effects of mild reaction process, excellent conductivity and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

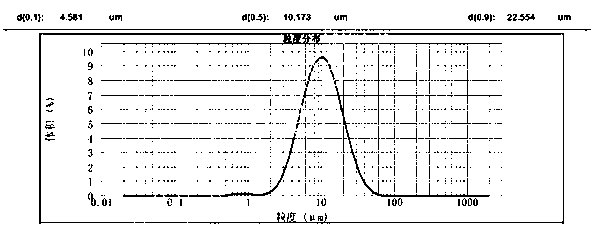

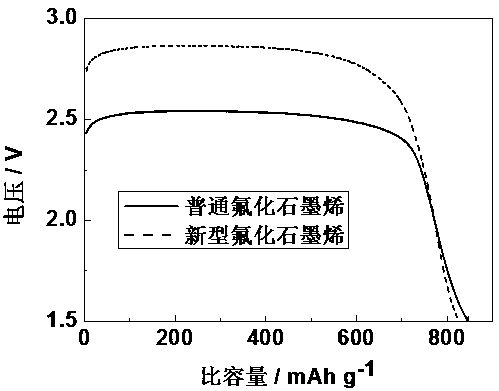

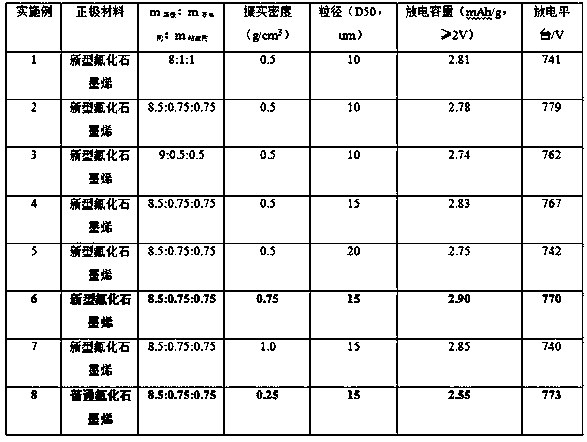

[0029] Preparation of new fluorinated graphene: put thermally reduced graphene with 10% oxygen content in a closed reaction furnace, and pass through F 2 / N 2 Gas mixture (F 2 The volume fraction is 2%), and the temperature was raised to 150 °C for 24 h at a heating rate of 10 °C / min to obtain the crude fluorinated graphene product. Then it was treated with KOH solution with a mass concentration of 5%, washed with deionized water four times, and baked at 110 °C for 12 h to obtain fluorinated graphene. After granulation and crushing, the tap density is 0.5 ~ 1.0 g / cm 3 , a new type of fluorinated graphene with a particle size of 10-20um. Among them, the purity of the new fluorinated graphene was measured to be 99.5%, and the content of fluorine element was 58%.

[0030] Preparation of high specific energy fluorinated graphene battery: N-methylpyrrolidone (NMP) is used as solvent, the new fluorinated graphene is used as positive electrode active material, and conductive agen...

Embodiment 1

[0033] The prepared 3.5g fluorinated graphene powder was put into a powder tablet press for compression molding, then transferred to a pulverizer for pulverization, and sieved to obtain a tap density of 0.5 g / cm 3, a new type of fluorinated graphene with a particle size (D50) of 10um; then, using NMP as a solvent, take 3g of the above-mentioned new type of fluorinated graphene, and 0.25g of carbon black, 0.125g of carbon nanotubes, and 0.375g of PVDF according to a mass ratio of 8 : 1:1 for homogenization, vacuum drying at 80°C for 12 hours, and pressing on the aluminum mesh by a roller press to obtain the positive electrode; then Celgard 2400 is used as the separator, lithium sheet is used as the negative electrode, and HR6066 is used as the electrolyte to assemble a fluorinated graphene battery .

[0034] The discharge platform of the fluorinated graphene battery was measured at 2.81V at a current density of 20 mA / g, and the specific energy was 741 mAh / g (cut-off voltage ≥ 2...

Embodiment 2

[0036] The prepared 3.5g fluorinated graphene powder was put into a powder tablet press for compression molding, then transferred to a pulverizer for pulverization, and sieved to obtain a tap density of 0.5 g / cm 3 , a new type of fluorinated graphene with a particle size (D50) of 10um; then, using NMP as a solvent, take 3g of the above-mentioned new type of fluorinated graphene, and 0.235g of carbon black, 0.118g of carbon nanotubes, and 0.353g of PVDF according to a mass ratio of 8.5 :0.75:0.75 for homogenization, vacuum drying at 80°C for 12 hours, and pressing on an aluminum grid by a roller press to obtain a positive electrode; then use Celgard 2400 as a separator, lithium sheet as a negative electrode, and HR6066 as an electrolyte to assemble a fluorinated graphene battery .

[0037] The discharge platform of the fluorinated graphene battery was measured at 2.78V at a current density of 20 mA / g, and the specific energy was 779 mAh / g (cut-off voltage ≥ 2V).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com