Insulator with diamond protective layer and production method thereof

A technology for insulators and protective layers, which is applied in the field of insulators with diamond protective layers and its production, can solve the problems of anti-flashover and anti-breakdown performance that cannot meet actual needs, achieve excellent ultraviolet resistance, excellent anti-pollution performance, reduce Effects of Pollution Flashover Accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, production has the suspension type resin insulator with diamond protection layer

[0024] 1) Shield the part of the outer surface of the suspended resin insulator body that is in contact with the wire;

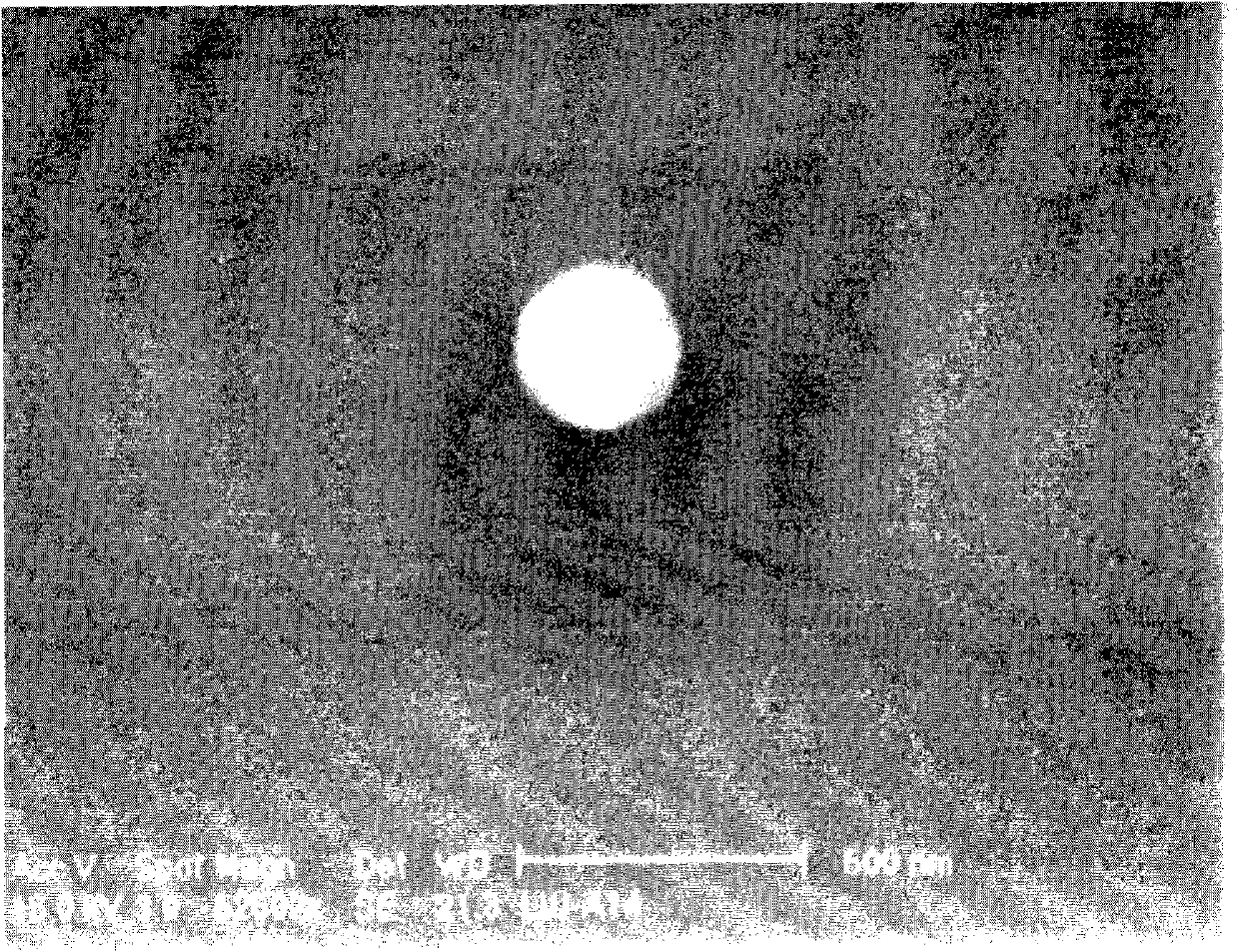

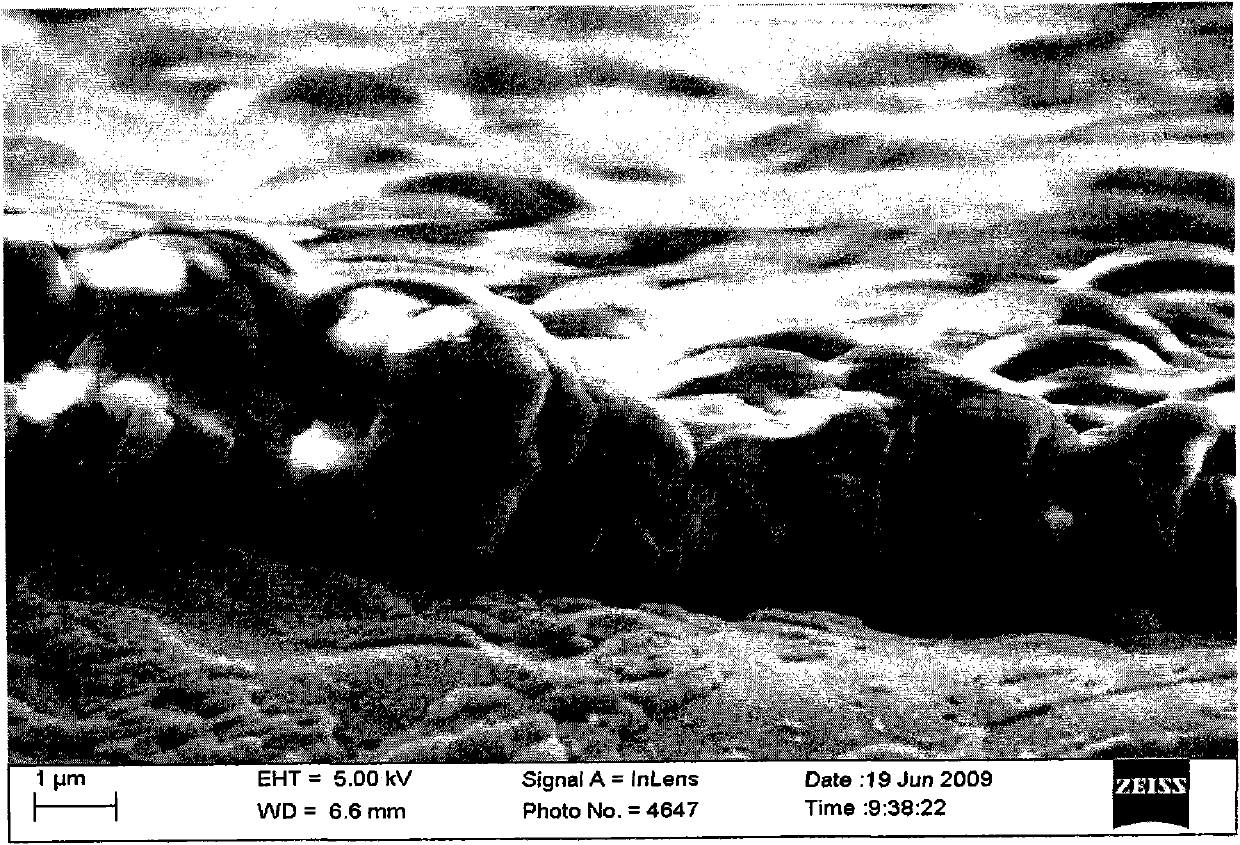

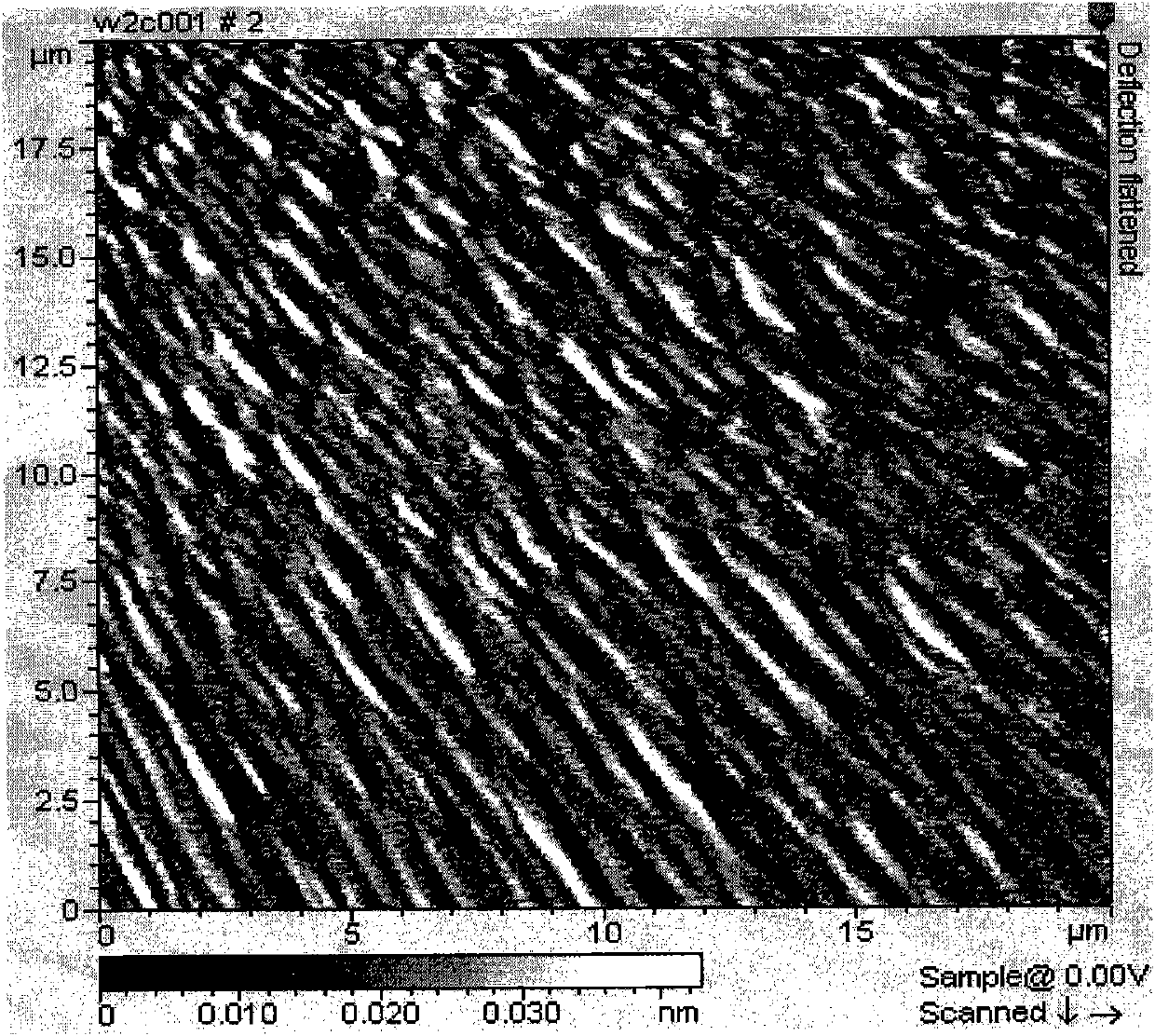

[0025] 2) Chemical vapor deposition of a layer of diamond protective layer on the outer surface of the insulator after the shielding treatment in step 1), and removing the shielding described in step 1), to obtain the insulator provided by the present invention. In the chemical vapor deposition step, the deposition equipment is an existing chemical vapor deposition furnace commonly used, and the raw material gas used is methane; during deposition, the deposition furnace is first evacuated to a vacuum degree of 10 -1 Pa, open the valves of argon and methane gas, keep the deposition pressure in the furnace at 1Pa, start chemical vapor deposition, the deposition rate is 6nm / min, the deposition temperature is room temperature, and stop after 10 minutes of depo...

Embodiment 2

[0027] Embodiment 2, production has the glass insulator of diamond protection layer

[0028] 1) Shield the part of the outer surface of the glass insulator body that is in contact with the wire;

[0029] 2) Chemical vapor deposition of a layer of diamond protective layer on the outer surface of the insulator after the shielding treatment in step 1), and removing the shielding described in step 1), to obtain the insulator provided by the present invention. In the chemical vapor deposition step, the deposition equipment is an existing chemical vapor deposition furnace commonly used, and the raw material gas used is natural gas; during deposition, the deposition furnace is first evacuated to a vacuum degree of 10 -1 Pa, open the valves of argon and natural gas, keep the deposition pressure in the furnace at 5Pa, start chemical vapor deposition, the deposition rate is 5nm / min, the deposition temperature is room temperature, and stop after 12 minutes of deposition, that is, on the ...

Embodiment 3

[0031]Embodiment 3, production has the ceramic insulator of diamond protection layer

[0032] 1) Shield the part of the outer surface of the ceramic insulator body that is in contact with the wire;

[0033] 2) Chemical vapor deposition of a layer of diamond protective layer on the outer surface of the insulator after the shielding treatment in step 1), and removing the shielding described in step 1), to obtain the insulator provided by the present invention. In the chemical vapor deposition step, the deposition equipment is an existing chemical vapor deposition furnace commonly used, and the raw material gas used is ethylene; the deposition furnace is first evacuated to a vacuum degree of 10 -1 Pa, open the valves of argon and ethylene gas, keep the deposition pressure in the furnace at 10Pa, start chemical vapor deposition, the deposition rate is 3nm / min, the deposition temperature is room temperature, and stop after 20 minutes of deposition, that is, in the ceramic insulator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com