Insulator structure

A technology of insulators and insulating layers, applied in insulators, supporting insulators, electrical components, etc., can solve the problems of unsolved silicone sleeves that cooperate with each other, difficulty in mass production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the utility model is described in further detail.

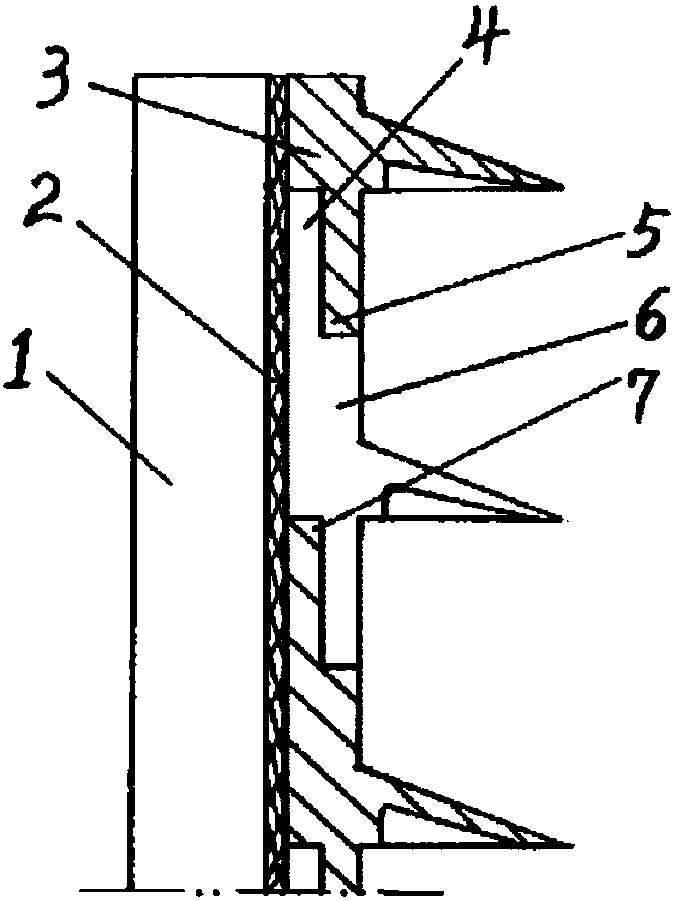

[0010] see figure 1 The utility model includes a porcelain column 1 and a silicone rubber umbrella cover 3 arranged on the porcelain column. The inner and outer edges of two adjacent silicone rubber umbrella covers 3 are respectively provided with concave platforms 4 and 7 that are interlocked up and down. And the glass fiber insulation layer 2 for adjustment is provided between the inner circular wall of the silicone rubber umbrella cover and the ceramic core that are interlocked with each other, and the inner edge concave platform of the silicone rubber umbrella cover is arranged at the lower or upper part of the inner edge, so The outer edge concave platform of the silicone rubber umbrella cover is set on the upper or lower part of the outer edge, and the glass fiber insulation layer for adjustment between the inner circular wall of the silicone rubber umbrella cover a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com