Manufacturing device and process of integral composite insulating arm applied to railway catenary

A railway catenary and composite insulation technology, applied in the direction of overhead lines, etc., can solve the problem that the tensile strength and bending strength cannot meet the technical requirements of the catenary arm, cannot meet the technical requirements of the catenary arm, and the fiber tension cannot meet the technical requirements. and other problems, to achieve excellent anti-pollution performance, excellent electrical insulation performance, and improve the overall insulation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

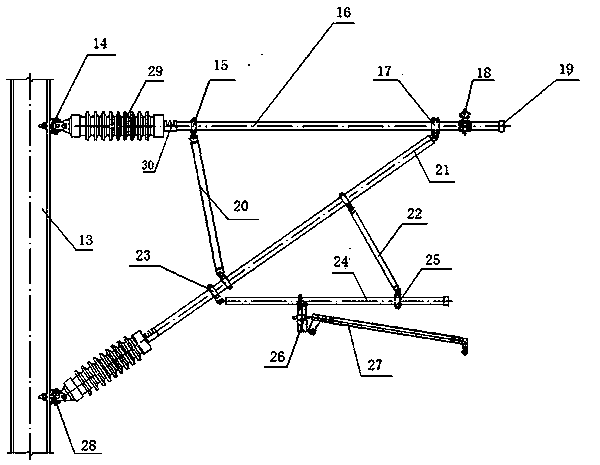

[0041] The present invention is further described below in conjunction with accompanying drawing.

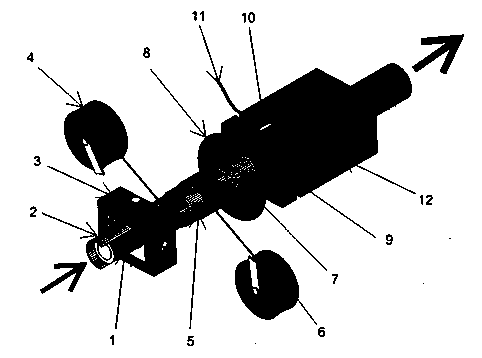

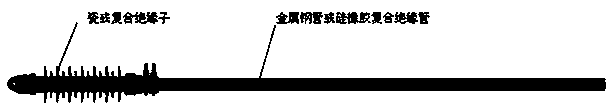

[0042] Such as figure 1 As shown, an integral composite insulating arm applied to the railway catenary. The composite insulating arm is composed of high-strength insulating pipe and insulating silicone rubber. The high-strength insulating pipe is pultruded through continuous fiber, continuous fiber winding and continuous The fiber braided network pipe is made by the triple combination process of simultaneous impregnation with resin rubber. The high-strength insulating pipe is covered with insulating silicone rubber. The inner and outer walls of the high-strength insulating pipe are made of continuous glass fibers wound clockwise and counterclockwise Evenly distributed, the longitudinal glass fiber is three layers, two hoop fiber winding layers are arranged in the middle of the three layers of longitudinal fibers, and the outermost layer is covered by a continuous fiber braided t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com