Method for producing fine denier acrylic tops

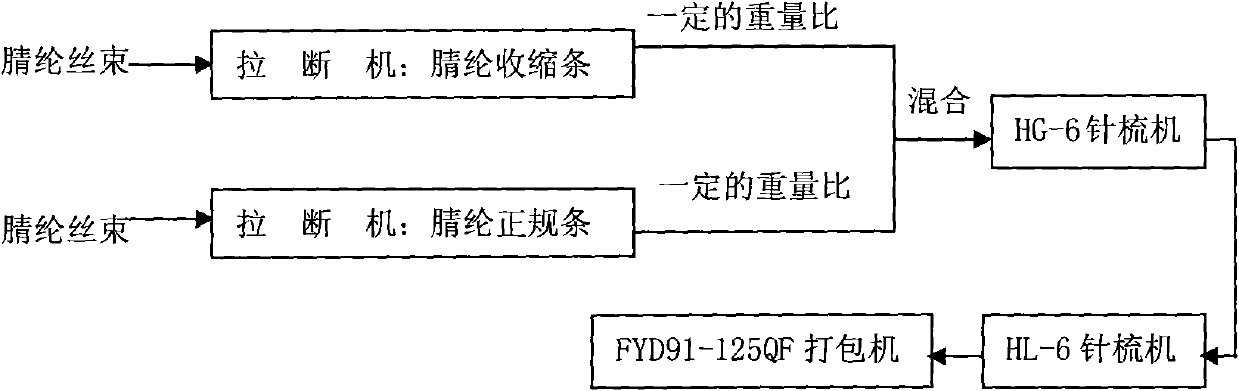

A production method and fine denier technology, applied in the direction of fiber bundles into fiber sliver/yarn, textiles and papermaking, drafting equipment, etc., can solve the difficulty of carding in the needle carding process, the difficulty of post-spinning, the length of fibers and the inconsistency of broken strips Evenness is not easy to control and other problems, to achieve the effect of low failure rate in the breaking process, meet the requirements of production equipment, and good dry quality of tops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

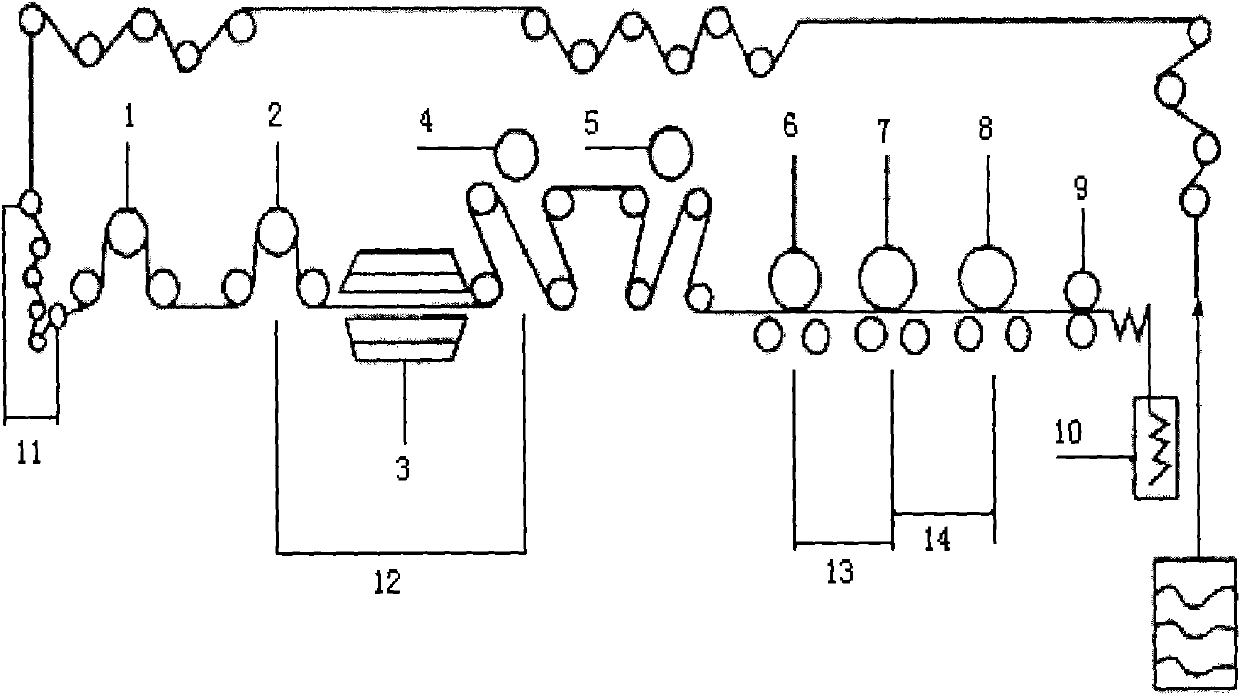

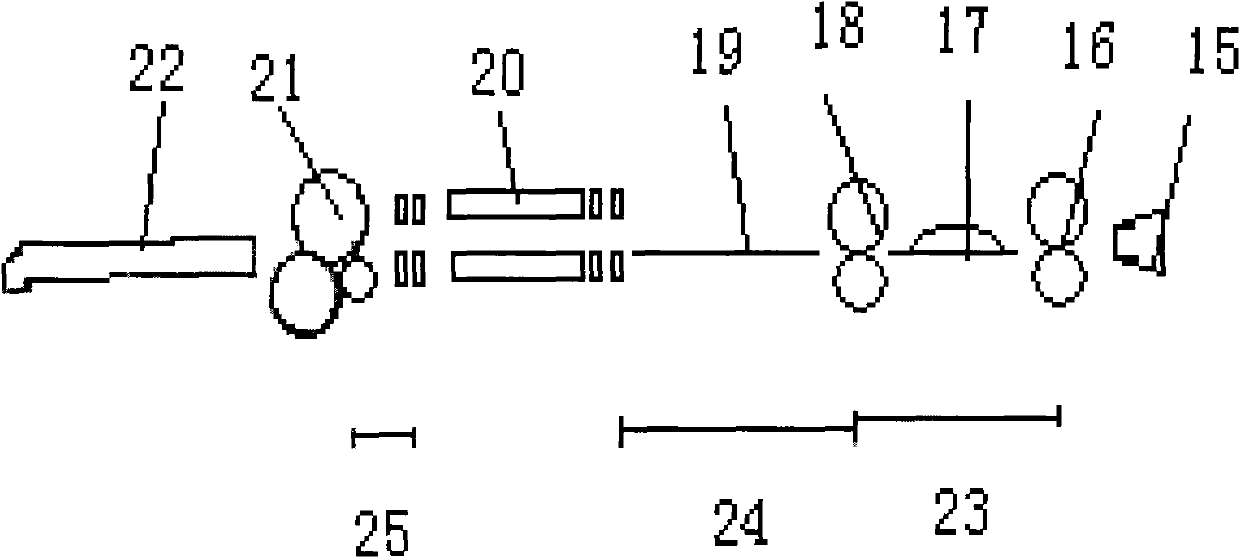

[0062] The stretching machine is composed of a wire guiding mechanism, a thermal stretching mechanism, a breaking mechanism, a steaming mechanism, a crimping mechanism, a dust collection mechanism, a cooling mechanism, a pressurizing mechanism and a transmission mechanism, etc. The total stretching ratio for producing fine-denier acrylic tops is 6.05~6.27 is suitable. The wire guide mechanism includes high-altitude wire guide frame and vertical wire guide frame. Zone 11, control span ≥ 18cm. The thermal stretching mechanism includes a feed roller 1 and a thermal stretching zone 12, and the thermal stretching zone is composed of a rear stretching roller 2, a front stretching roller 4, and a heating plate 3. The drafting ratio of the thermal stretching zone is 1.30 times, and the temperature of the heating plate 3 is It is adjusted by the button and controlled at 135°C. The breaking mechanism is composed of pre-breaking roller 5, main breaking roller 6, re-cutting roller 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com