Permanganate/montmorillonite nano composite material as well as preparation method and application thereof

A nanocomposite material, potassium permanganate technology, applied in the application of potassium permanganate/montmorillonite nanocomposite material as an oxygen storage material, potassium permanganate/montmorillonite nanocomposite material and its preparation field, can Solve the problems of not being easy to fix, reduce the reaction rate of oxygen generators, and hinder the reaction of potassium permanganate, etc., and achieve the effects of convenient operation, good stability, gas buffer performance, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

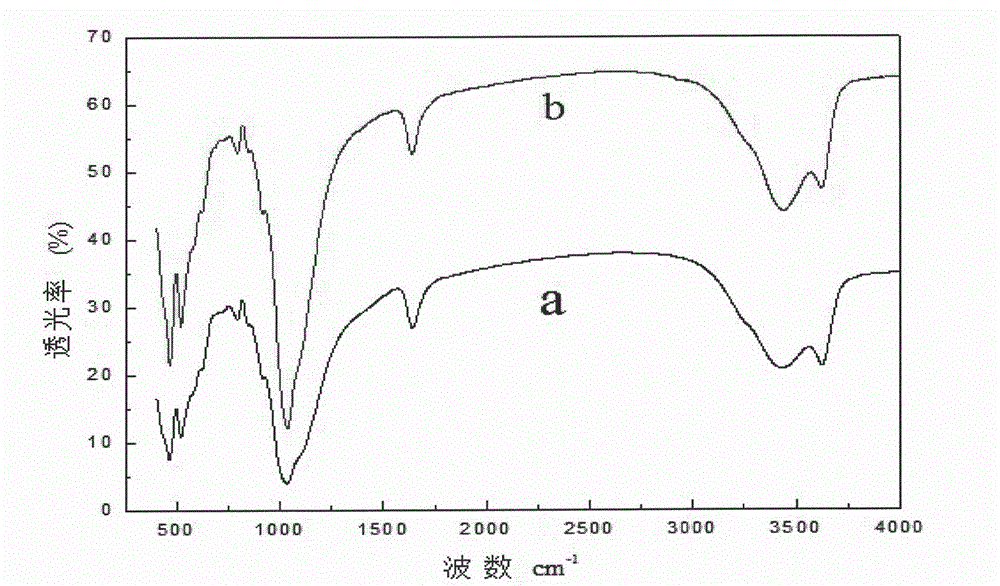

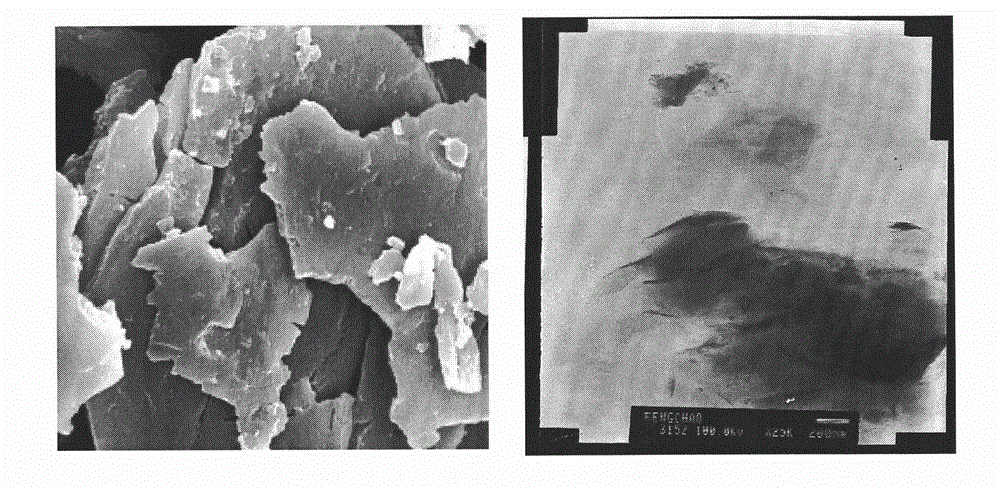

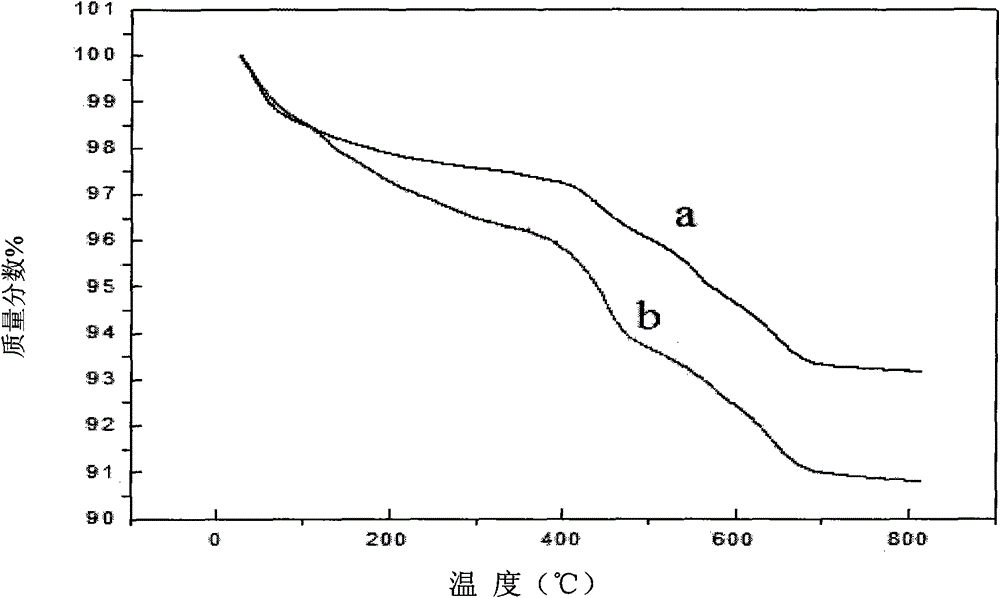

[0051] Embodiment 1, the preparation of potassium permanganate / montmorillonite nanocomposite

[0052] (1) Add montmorillonite to water at a mass ratio of 1:10, stir to make it evenly dispersed, and form a montmorillonite dispersion;

[0053] Potassium permanganate solid is dissolved in water with a mass ratio of 1:3 to form a potassium permanganate solution;

[0054] (2) The montmorillonite dispersion liquid is mixed with potassium permanganate solution (the mass ratio of potassium permanganate and montmorillonite in the mixed system is 2:1), placed in an ultrasonic disperser, at room temperature, 70-80Hz ultrasonic wave Continue to react and stir for 20-24 hours after dispersing at high temperature for 2 hours;

[0055] (3) After the reaction is finished, suction filter, wash, and discard the filtrate to obtain a solid compound;

[0056] (4) putting the solid compound into an oven for drying, crushing into granules or grinding into powder to obtain the potassium permanganat...

Embodiment 2

[0057] Embodiment two, the preparation of potassium permanganate / montmorillonite nanocomposite

[0058] (1) Montmorillonite is added to water with a mass ratio of 1:8, and stirred to make it evenly dispersed to form a montmorillonite dispersion;

[0059] Potassium permanganate solid is dissolved in water with a mass ratio of 1:6 to form a potassium permanganate solution;

[0060] (2) The montmorillonite dispersion liquid is mixed with potassium permanganate solution (the mass ratio of potassium permanganate and montmorillonite in the mixed system is 1:1), placed in an ultrasonic disperser, at room temperature, 70-80Hz ultrasonic wave Continue to react and stir for 20-24 hours after dispersing at high temperature for 2 hours;

[0061] (3) After the reaction is finished, suction filter, wash, and discard the filtrate to obtain a solid compound;

[0062] (4) putting the solid compound into an oven for drying, crushing into granules or grinding into powder to obtain the potassiu...

Embodiment 3

[0063] Embodiment three, the preparation of potassium permanganate / montmorillonite nanocomposite

[0064] (1) Add montmorillonite to water with a mass ratio of 1:12, stir to make it evenly dispersed, and form a montmorillonite dispersion;

[0065] Potassium permanganate solid is dissolved in water with a mass ratio of 1:5 to form a potassium permanganate solution;

[0066] (2) The montmorillonite dispersion is mixed with potassium permanganate solution (the mass ratio of potassium permanganate to montmorillonite in the mixed system is 1.5:1), placed in an ultrasonic disperser, and at room temperature, 70-80Hz ultrasonic Continue to react and stir for 20-24 hours after dispersing at high temperature for 2 hours;

[0067] (3) After the reaction is finished, suction filter, wash, and discard the filtrate to obtain a solid compound;

[0068] (4) putting the solid compound into an oven for drying, crushing into granules or grinding into powder to obtain the potassium permanganate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com