High-temperature-resistant and corrosion-resistant alloy and preparation method thereof

A technology of anti-corrosion and high-temperature resistance, applied in the field of high-temperature and anti-corrosion alloy and its preparation, can solve problems such as high price, and achieve the effect of promoting passivation, reducing material cost, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of high temperature and corrosion resistant alloy;

[0037] (1) Chemical composition:

[0038] C: 3.5%, Si: 2.62%, Mn: 0.34%,

[0039] P: 0.068%, S: 0.07%, Cu: 0.33%,

[0040] Cr: 0.30%, RE: 0.022%, Fe: balance;

[0041] (2) Oxidation test: (800°C for 150 hours) 0.36g / m 2 ,

[0042] Anti-growth test: (800°C for 150 hours) 0.19%,

[0043] Corrosion resistance test: the corrosion medium is 30% NaOH solution (boiling) 2.8g / m 2 ;

[0044] (3) The service life of the soup spoon made of this alloy material is 30 days.

Embodiment 2

[0045] Embodiment 2: a kind of high temperature and corrosion resistant alloy;

[0046] (1) Chemical composition

[0047] C: 3.45%, Si: 2.68%, Mn: 0.36%,

[0048] P: 0.065%, S: 0.074%, Cu: 0.58%,

[0049] Cr: 0.46%, RE: 0.036%, Fe: balance;

[0050] (2) Metallographic: Most graphite is lumpy and flocculent, and a small amount is spherical and wormlike (see attached figure 1 );

[0051] (3) Oxidation test: (800°C for 150 hours) 0.30g / m 2 ,

[0052] Anti-growth test: (800°C for 150 hours) 0.16%,

[0053] Corrosion resistance test: the corrosion medium is 30% NaOH solution (boiling) 2.4g / m 2 ;

[0054] (4) The service life of the spoon product made of this alloy material reaches 45 days.

Embodiment 3

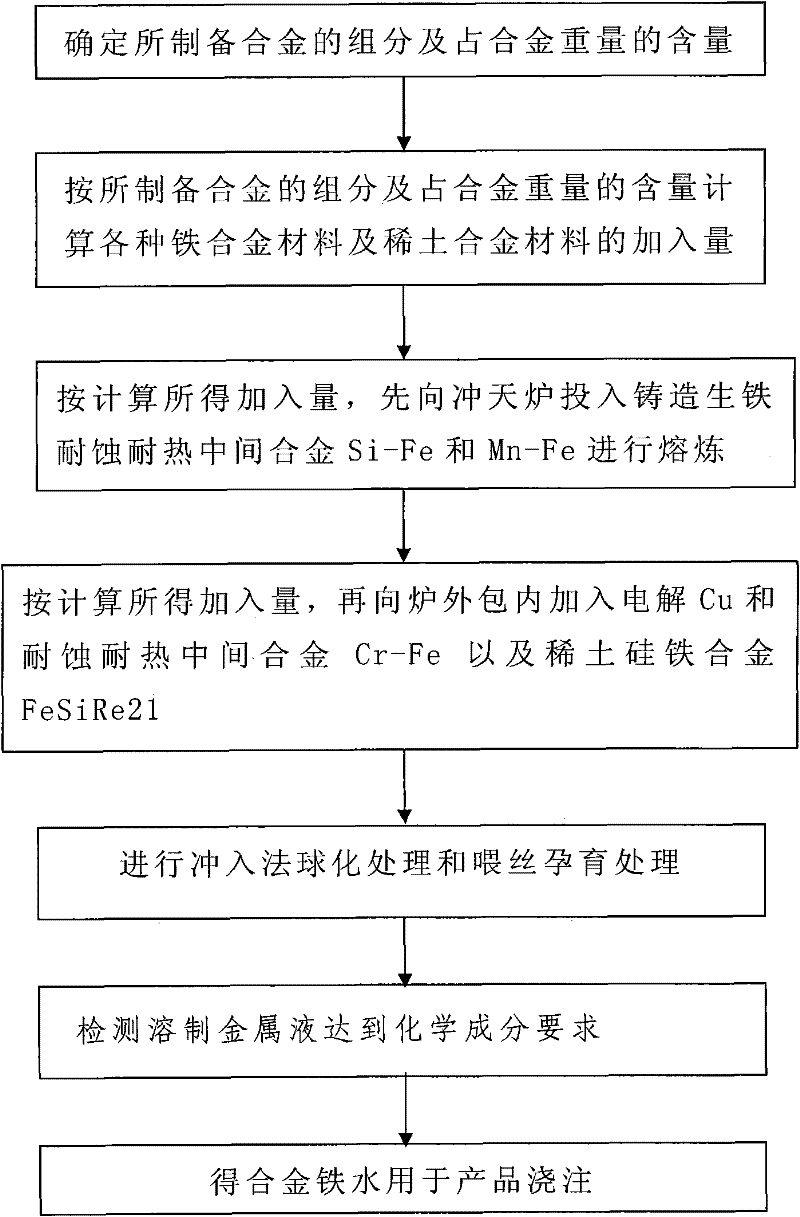

[0055] Embodiment 3: a kind of preparation method of high temperature resistant corrosion resistant alloy, comprising:

[0056] (1) Determine the composition of the prepared alloy and the content of the alloy weight as follows:

[0057] C: 3.4%, Si: 2.91%, Mn: 0.4%,

[0058] P: <0.06%, S: <0.065%, Cu: 0.92%,

[0059] Cr: 0.72%, Re: 0.042%, Fe: balance;

[0060](2) calculate the addition of various iron alloy materials and rare earth alloy materials according to the composition of the alloy and the content of the alloy weight;

[0061] (3) Add cast iron, corrosion-resistant and heat-resistant master alloy Si-Fe and Mn-Fe to the cupola earlier according to the calculated addition amount;

[0062] (4) According to the calculated addition amount, add electrolytic Cu, corrosion-resistant and heat-resistant master alloy Cr-Fe and rare earth ferrosilicon alloy FeSiRe21 into the furnace outer bag;

[0063] Melting temperature of molten iron: 1450°C, melting speed of molten iron: 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com