Improvement on method for preparing complex of polyvinylpyrrolidone grafted with natural polymer or water-soluble derivate thereof and iodine derivate

A technology of vinylpyrrolidone and natural polymer is applied in the field of preparation improvement of natural polymer or its water-soluble derivative grafted polyvinylpyrrolidone complexed iodine derivative, and can solve the problem of high energy consumption, uneconomical and long drying time. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

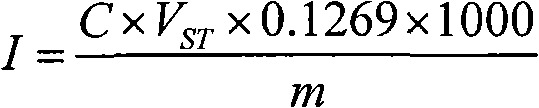

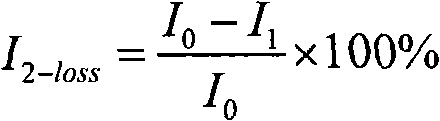

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Preparation of CMCTS-g-(PAANa-co-PVP)

[0061] After fully dissolving 1.5 parts of carboxymethyl chitosan in distilled water, control the temperature of the system at 60° C., add azobisisobutyronitrile with a total mass of acrylate and N-vinylpyrrolidone of 2.5 wt % under nitrogen protection, and react After 30 minutes, add the unsaturated vinyl monomer mixture that is 10:1 with carboxymethyl chitosan mass ratio, the massfraction of the acrylic acid neutralized with sodium hydroxide in this mixture is 70%, the N-vinylpyrrolidone The mass fraction is 30%, and the cross-linking agent N,N'-methylenebisacrylamide of 2wt% monomer is added at the same time, the total water in the control system and the monomer mass ratio are 15:1, and the reaction is carried out at 60°C for 8 hours After the reaction is stopped, the product is precipitated with ethanol with a mass ratio of 12:1 to the monomer, and then the precipitate is broken up by high-speed stirring at 2500 rp...

Embodiment 2

[0063] Dissolve CMCTS-g-(PAANa-co-PVP) powder in distilled water 10 times its mass, neutralize the solution to pH=6.0 through 5% dilute acetic acid solution, add CMCTS-g-(PAANa-co- PVP) long-chain anionic surfactant sodium dodecylsulfonate with a mass fraction of 10%, stirred evenly at 50°C. In addition, it is 15% iodine elemental powder and the potassium iodide powder that is 1.1: 1 with the molar ratio of the iodine elemental substance to add the tert-butyl alcohol / butanol / In the water mixed solution (tert-butanol accounts for 50%, water accounts for 50%), stir at 50°C to dissolve the iodine evenly, then slowly add the solution to the CMCTS-g-(PAANa-co-PVP) aqueous solution , kept warm in a water bath, stirred and reacted for 5 hours, and then the product was concentrated by distillation under reduced pressure, and excess uncomplexed iodine was removed. The product is fully soaked in n-heptane until the supernatant is colorless and transparent, the supernatant is poured ou...

Embodiment 3

[0065]Dissolve CMCTS-g-(PAANa-co-PVP) powder in distilled water 10 times its mass, neutralize the solution to pH=5.3 by 5% dilute acetic acid solution, and take another 25% of the mass fraction of the graft copolymer % iodine elemental powder and the potassium iodide powder that the molar ratio of iodine elemental substance is 1.1: 1 joins together in the DMSO / water mixed solution that the mass ratio of graft copolymer is 2: 1 (DMSO accounts for 30%, water accounts for 70%) %), after stirring at 55°C to make the iodine dissolve evenly, slowly add the solution into the CMCTS-g-(PAANa-co-PVP) aqueous solution, and keep stirring in a water bath at 55°C for 30 minutes, Add the long-chain nonionic surfactant lauryl alcohol polyoxyethylene ether that accounts for CMCTS-g-(PAANa-co-PVP) massfraction 15%, continue stirring reaction in the water bath of this temperature for 5 hours and pass decompression Distillation concentrates the product and removes excess uncomplexed iodine. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com