Copolymer gel electrolyte and preparation method thereof

A technology of gel electrolyte and copolymer, which is applied in the direction of capacitor electrolyte/absorbent, circuit, photosensitive equipment, etc. It can solve the problems of solvent volatilization, corrosion of counter electrode, short life, and difficulty in battery packaging, etc., and achieves mild operating conditions and improved performance. Conductivity, effect of reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step is the preparation and purification of (acrylic acid / allyloxy polyethylene glycol) copolymer

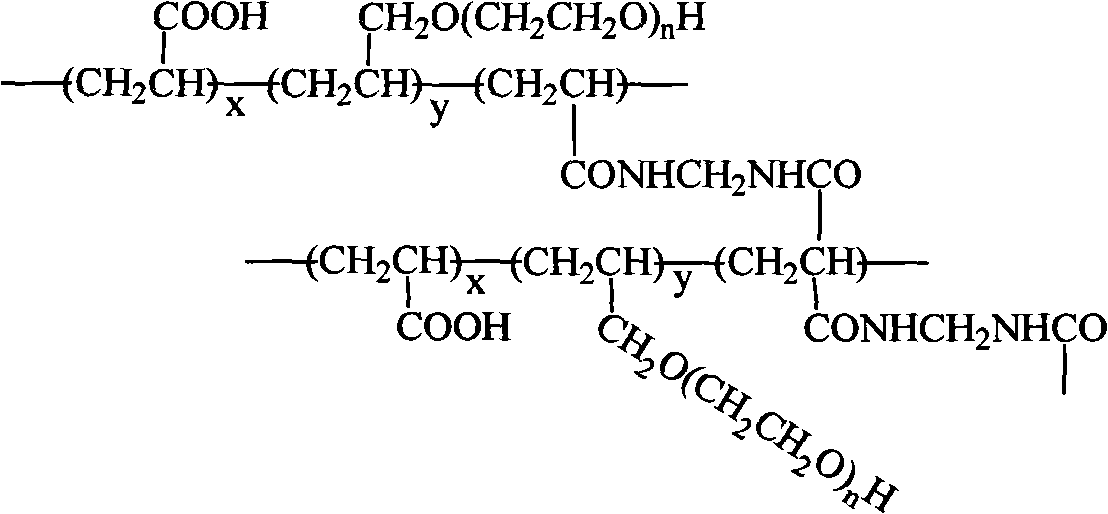

[0033] A, Preparation of (acrylic acid / allyloxy polyethylene glycol) copolymer

[0034] Add 3.2 g of acrylic acid, 0.064 g of initiator ammonium persulfate and 0.016 g of sodium bisulfite, 0.064 g of cross-linking agent N, N-methylene bisacrylamide (Bis), and 5 g of water in the flask. Nitrogen gas is supplied at room temperature. Stir and prepolymerize for 0.5h; then slowly add dropwise a 5g aqueous solution of 2g of allyloxy polyethylene glycol to the above system, and stir for 12h at room temperature under nitrogen atmosphere; the molecular formula of allyloxy polyethylene glycol is CH 2 =CHCH 2 O(CH 2 CH 2 O) n H, n represents an integer of 44; the quality of acrylic acid, allyloxy polyethylene glycol, initiator ammonium persulfate and sodium bisulfite, crosslinking agent N, N-methylene bisacrylamide (Bis) and water The ratio is 1:0.625:0.2:0.05:0.2:3.12; pour th...

Embodiment 2

[0043] The first step is the preparation and purification of (acrylic acid / allyloxy polyethylene glycol) copolymer

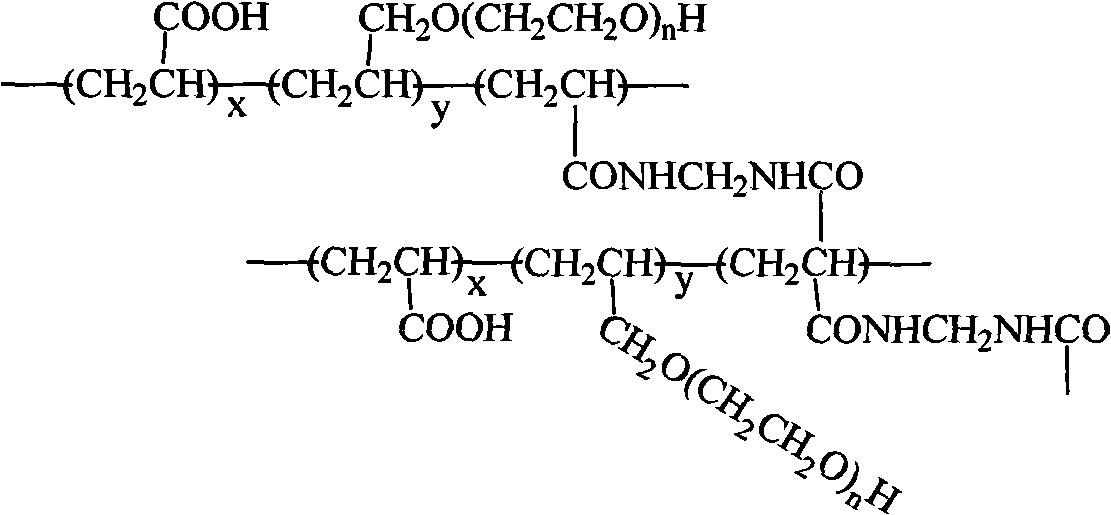

[0044] A, Preparation of (acrylic acid / allyloxy polyethylene glycol) copolymer

[0045] Add 3.2g of acrylic acid, 0.064g of initiator ammonium persulfate and 0.016g of sodium bisulfite, 0.016g of cross-linking agent N,N-methylenebisacrylamide (Bis), and 5g of water into the flask, venting nitrogen, room temperature Stir and prepolymerize for 0.5h; then slowly add dropwise a 5g aqueous solution of 2g of allyloxy polyethylene glycol to the above system, and stir for 12h at room temperature under nitrogen atmosphere; the molecular formula of allyloxy polyethylene glycol is CH 2 =CHCH 2 O(CH 2 CH 2 O) n H, n represents an integer of 44; the quality of acrylic acid, allyloxy polyethylene glycol, initiator ammonium persulfate and sodium bisulfite, crosslinking agent N, N-methylene bisacrylamide (Bis) and water The ratio is 1:0.625:0.2:0.05:0.005:3.12; pour the solution in ...

Embodiment 3

[0052] The first step is the preparation and purification of (acrylic acid / allyloxy polyethylene glycol) copolymer

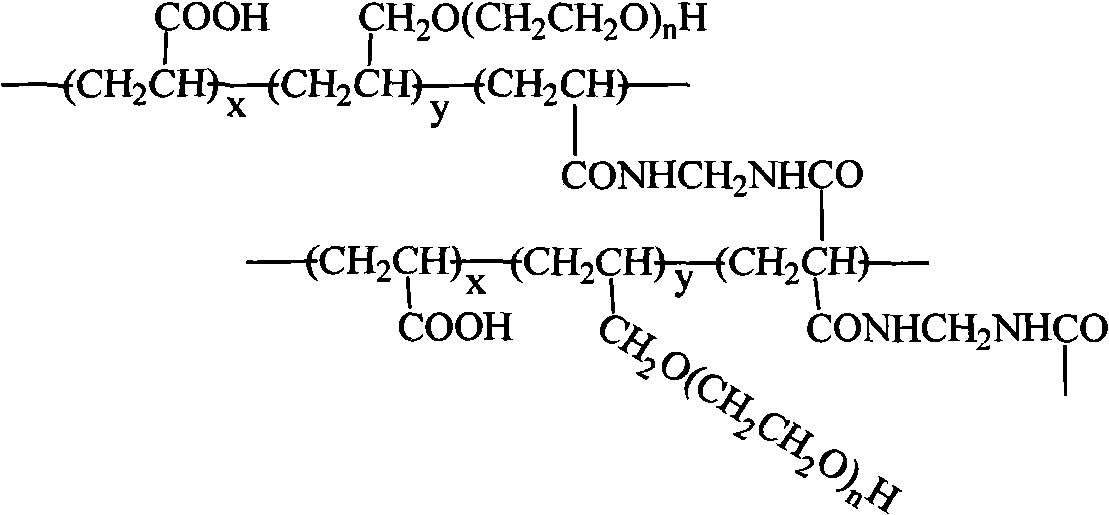

[0053] A, Preparation of (acrylic acid / allyloxy polyethylene glycol) copolymer

[0054] Add 3.2g of acrylic acid, 0.064g of initiator ammonium persulfate and 0.016g of sodium bisulfite, 0.032g of cross-linking agent N,N-methylenebisacrylamide (Bis), and 5ml of water in the flask, nitrogen gas, room temperature Stir and prepolymerize for 0.5h; then slowly add dropwise a 5ml aqueous solution of 2g of allyloxy polyethylene glycol to the above system, and stir for 12h at room temperature under nitrogen atmosphere; the molecular formula of allyloxy polyethylene glycol is CH 2 =CHCH 2 O(CH 2 CH 2 O) n H, n represents an integer of 44; the quality of acrylic acid, allyloxy polyethylene glycol, initiator ammonium persulfate and sodium bisulfite, crosslinking agent N, N-methylene bisacrylamide (Bis) and water The ratio is 1:0.625:0.02:0.005:0.01:3.12; pour the solution in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com