Preparation method of reproducible SiO2/PAM core-shell composite nano antibacterial particles

A nano-antibacterial particle and core-shell technology, which is applied in the field of antibacterial particle preparation, can solve the problems of poor washing resistance and low bonding fastness, and achieve the effects of low production cost, excellent antibacterial effect and function, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The renewable SiO of the embodiment of the present invention 2 The preparation method of / PAM core-shell composite nanometer antibacterial particles is carried out according to the following specific steps:

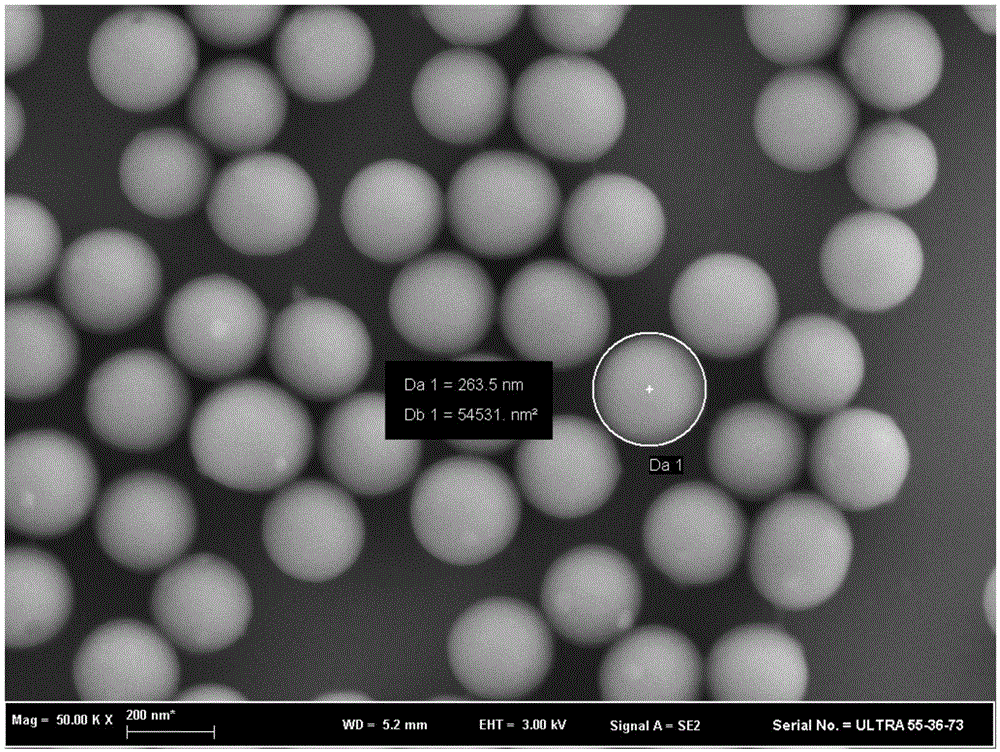

[0046] Step 1, using tetraethyl orthosilicate (TEOS) as a precursor, in a mixed solution of alcohol, water and ammonia, to prepare nano-SiO by hydrolysis, dehydration and polymerization 2 particle. First, 50 parts of TEOS are added to 100 parts of ethanol with a mass fraction of 94wt% to prepare a mixed solution; secondly, the prepared mixed solution is mixed with 35 parts of deionized water, 100 parts of ethanol with a mass fraction of 94wt% and a mass fraction of 28wt% NH 4 OH solution was mixed, adding 4 parts of NH 4 OH NH 4 OH solution to adjust SiO 2 particle size, and then further reacted in a constant temperature magnetic stirrer at a temperature of 30°C for 24h to make SiO 2 The particle size distribution is between 250-300nm;

[0047] Nano-SiO was t...

Embodiment 2

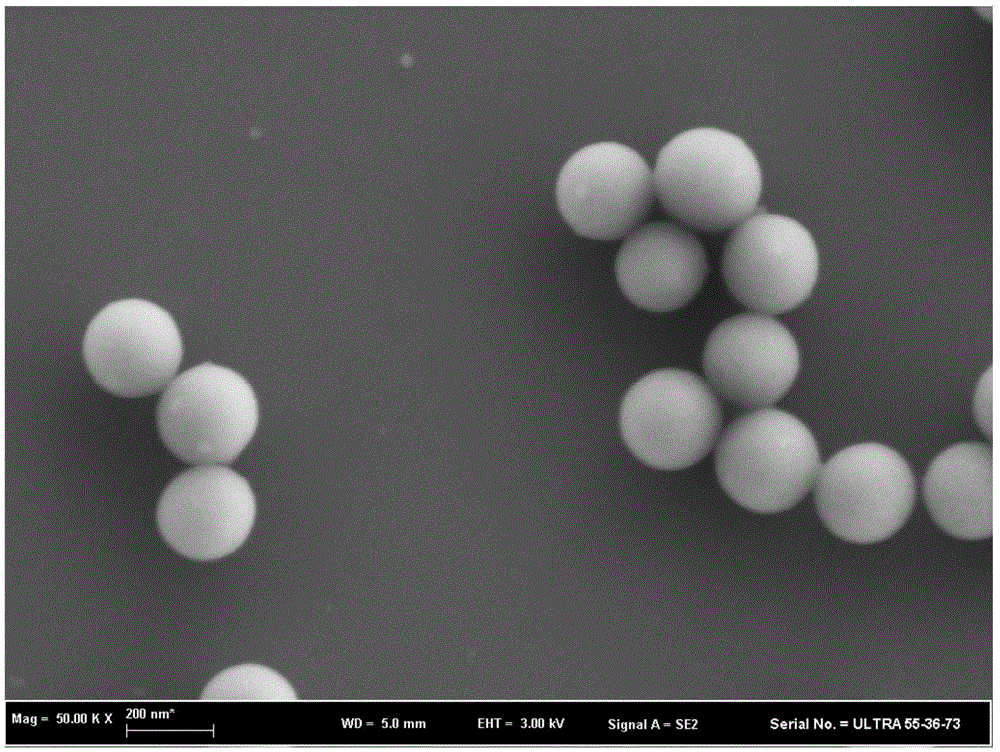

[0058] Follow the same method steps as in Example 1, except that in this example, in step 1, 5 parts of NH 4 OH NH 4 OH solution to adjust SiO 2 particle size, and then further reacted in a constant temperature magnetic stirrer at a temperature of 30°C for 24h to make SiO 2 The particle size distribution is between 170 and 200nm; Step 2 is the same as Step 2 of Example 1; in Step 3, after adding cation and anion PAM, the time to continue stirring is 4h; Step 4 is the same as Step 4 of Example 1; Core-shell SiO with a diameter of 335.0nm 2 / Halamine nanocomposite antibacterial particles.

Embodiment 3

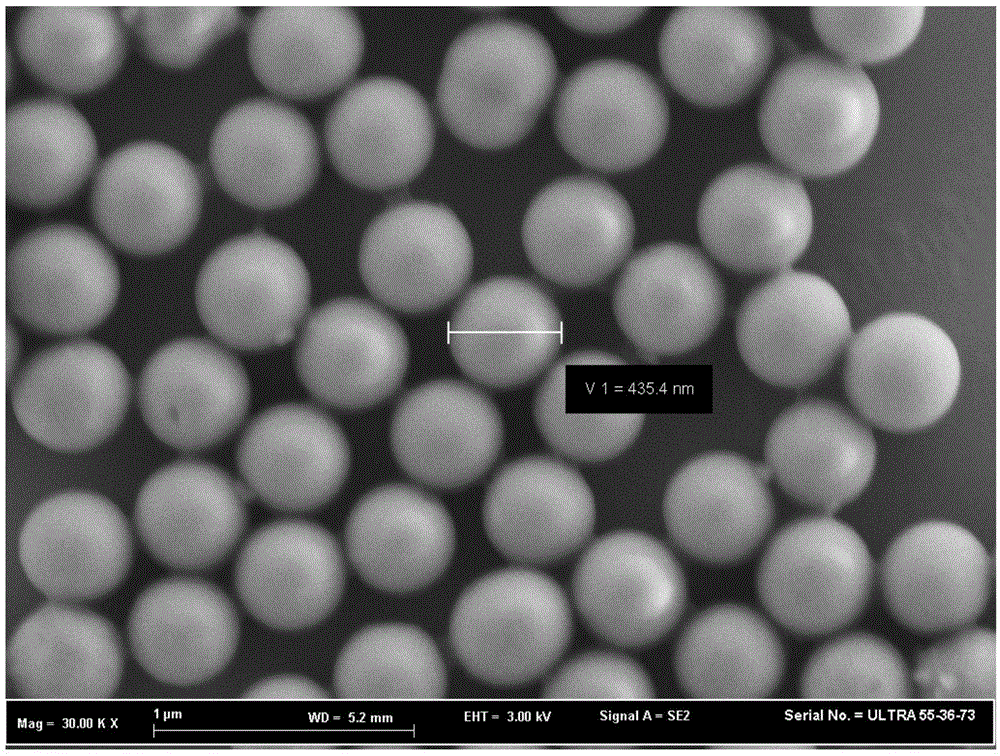

[0060] Steps 1 to 2 of this example are the same as Steps 1 to 2 of Example 1, except that in Step 3, 0.3 g of cationic PAM is added, and stirred for 4 hours in a constant temperature mixer at a temperature of 20° C. fully dissolved; then add 0.3g of anionic PAM, and continue to stir for 4h in a constant temperature mixer at a temperature of 20°C; Step 4 is the same as Step 4 in Example 1 to obtain SiO with a particle size of 435.4nm and a core-shell structure. 2 / Halamine nanocomposite antibacterial particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com