A three-dimensional composite oxide catalyst for simultaneously eliminating NO and soot particles, its preparation method and use

A composite oxide and three-dimensional composite technology, which is applied in the field of three-dimensional ordered macroporous composite oxide catalysts and their preparation, can solve the problems of unsatisfactory catalytic activity, inability to remove harmful substances, and easy agglomeration of catalysts, etc., to achieve effective Good for catalyst activity, short preparation cycle, and full use of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

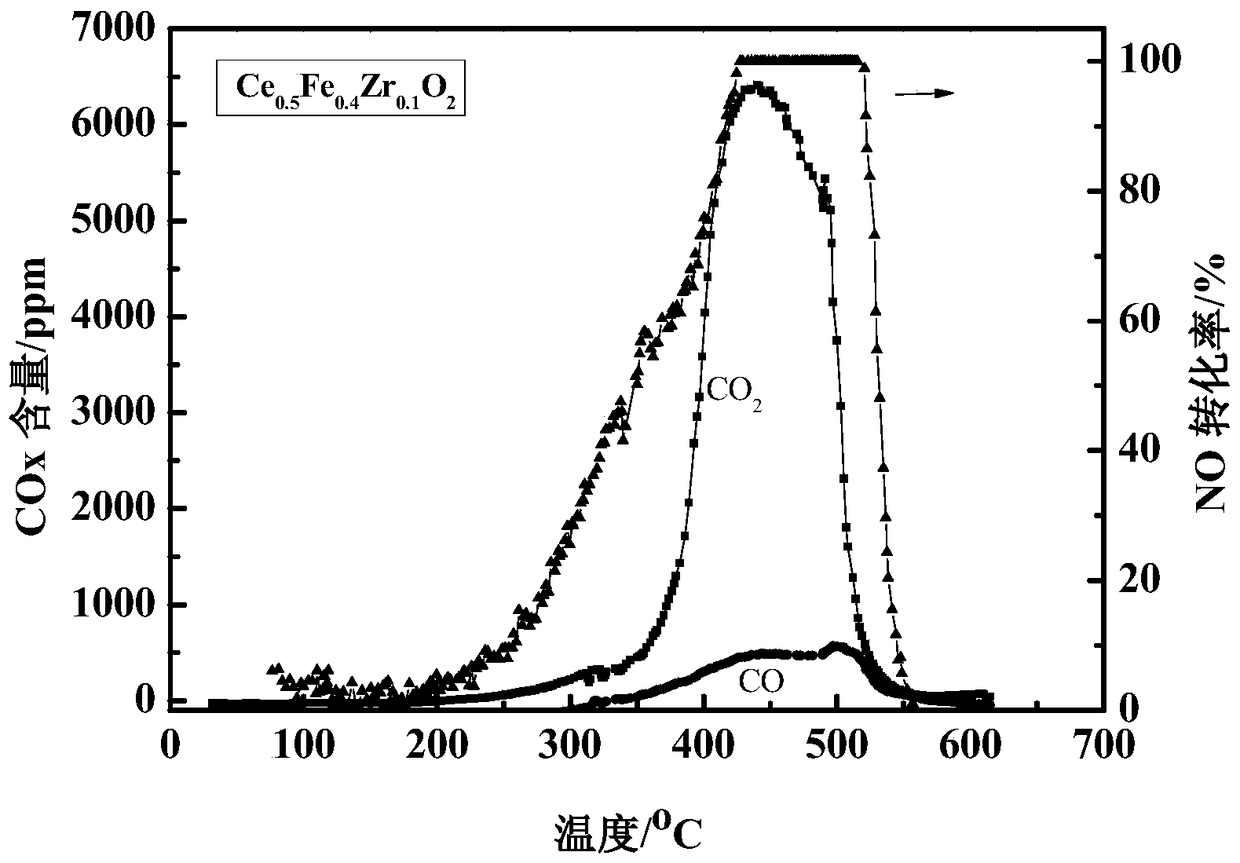

[0067] Embodiment 1: preparation composition is Ce 0.5 Fe 0.4 Zr 0.1 o 2 three-dimensional composite oxide catalyst

[0068] At a stirring rate of 200r / min, 5.48g cerium ammonium nitrate, 3.23g ferric nitrate and 0.65g zirconium oxychloride (wherein the molar ratio of cerium ammonium nitrate, ferric nitrate and zirconium oxychloride is 5:4:1 ) was dissolved in a mixed solution of absolute ethanol and methanol, and then stirred evenly at 25°C to form a precursor solution; 6g of the template polymethyl methacrylate (PMMA) was weighed and added to the precursor solution at room temperature (15-25 ℃) impregnated for 12 hours, then suction filtered, and the obtained solid was dried at 40 ℃ for 2 hours; the dried obtained solid was heated from room temperature (15-25 ℃) to 310 ℃ in a tubular heating furnace and kept for 4 hours, and then heated at the same heating rate Raise the temperature to 450°C and keep it warm for 4h, then the composition becomes Ce 0.5 Fe 0.4 Zr 0.1 o ...

Embodiment 2

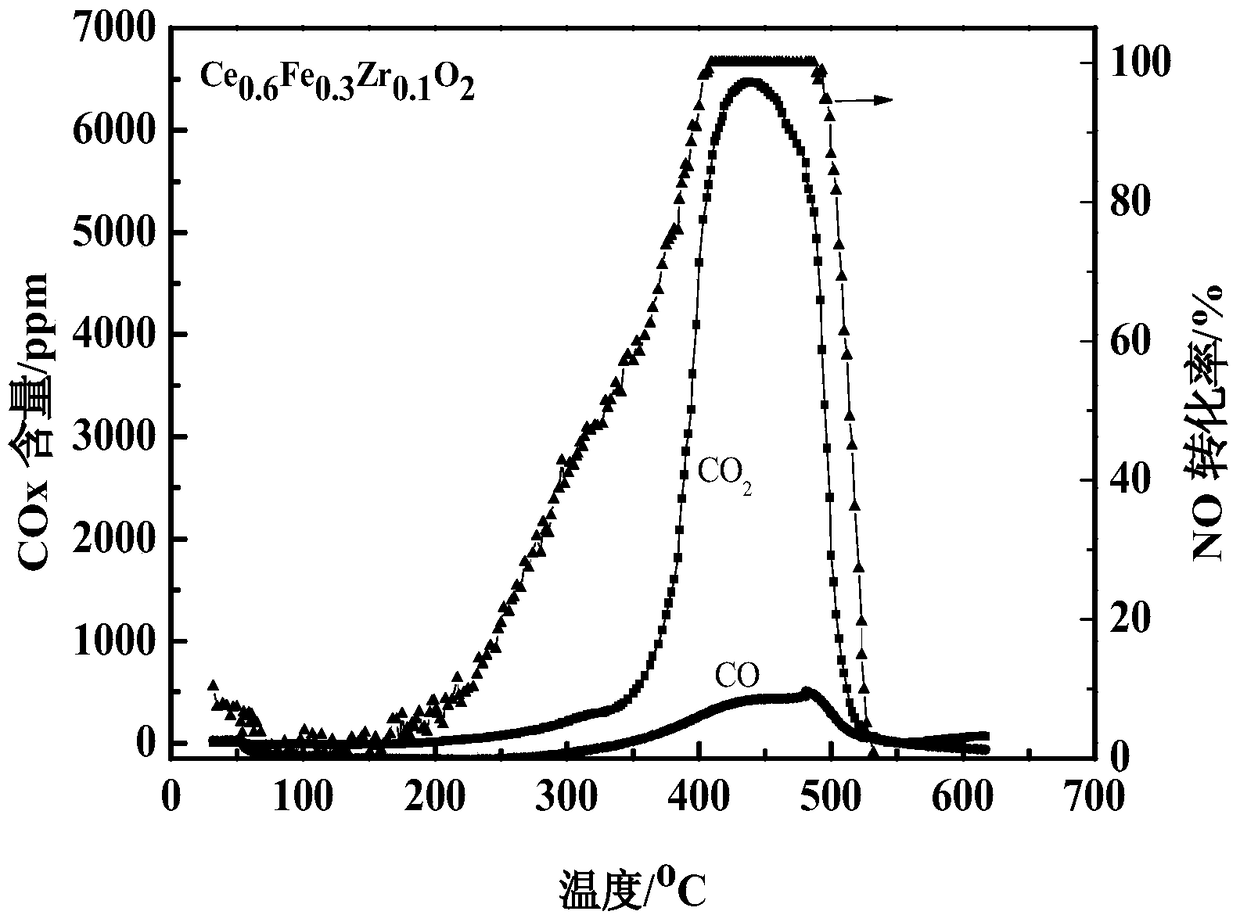

[0072] Embodiment 2: preparation composition is Ce 0.6 Fe 0.3 Zr 0.1 o 2 three-dimensional composite oxide catalyst

[0073] Dissolve 6.58g of cerium ammonium nitrate, 2.42g of ferric nitrate and 0.86g of zirconium nitrate (the molar ratio of cerium ammonium nitrate, ferric nitrate and zirconium nitrate is 6:3:1) at a stirring rate of 150-200r / min In a mixed solution of absolute ethanol and methanol, then stir evenly at 30°C to form a precursor solution; weigh 8g of the template agent polymethyl methacrylate (PMMA) and add it to the precursor solution at room temperature (15-25°C) Immerse for 15 hours, then filter with suction, and dry the obtained solid at 50°C for 3 hours; heat the dried obtained solid from room temperature (15-25°C) to 310°C in a tubular heating furnace and keep it warm for 4 hours, and then raise the temperature to 500°C and keep it warm for 5h, the composition is Ce 0.6 Fe 0.3 Zr 0.1 o 2 three-dimensional composite oxide catalysts.

[0074] In a ...

Embodiment 3

[0076] Embodiment 3: preparation composition is Ce 0.7 Fe 0.2 Zr 0.1 o 2 three-dimensional composite oxide catalyst

[0077] Dissolve 7.68g of cerium ammonium nitrate, 1.62g of ferric nitrate and 0.86g of zirconium nitrate (the molar ratio of cerium ammonium nitrate, ferric nitrate and zirconium nitrate is 7:2:1) at a stirring rate of 250-300r / min In a mixed solution of absolute ethanol and methanol, then stir evenly at 40°C to form a precursor solution; weigh 8g of the template polymethyl methacrylate (PMMA) and add it to the precursor solution at room temperature (15-25°C) Immerse for 18 hours, then suction filter, and dry the obtained solid at 65°C for 4 hours; heat the dried obtained solid from room temperature (15-25°C) to 310°C in a tubular heating furnace and keep it warm for 4 hours, and then raise the temperature to 550°C and keep it warm for 4h, the composition is Ce 0.7 Fe 0.2 Zr 0.1 o 2 three-dimensional composite oxide catalysts.

[0078] In a continuous-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com