Multistage combustor, molten steel tank preheating equipment and application method thereof

A technology of burner and stage combustion, which is applied in the direction of combustion method, burner, lighting and heating equipment, etc., which can solve the problem of capital occupation, high maintenance cost and management cost, long baking operation time of turnover steel tank, and tapping temperature requirements Higher problems, to achieve the effect of promoting uniform distribution and heat transfer, reducing the generation of hot spots in the tank, and uniform and diffuse flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

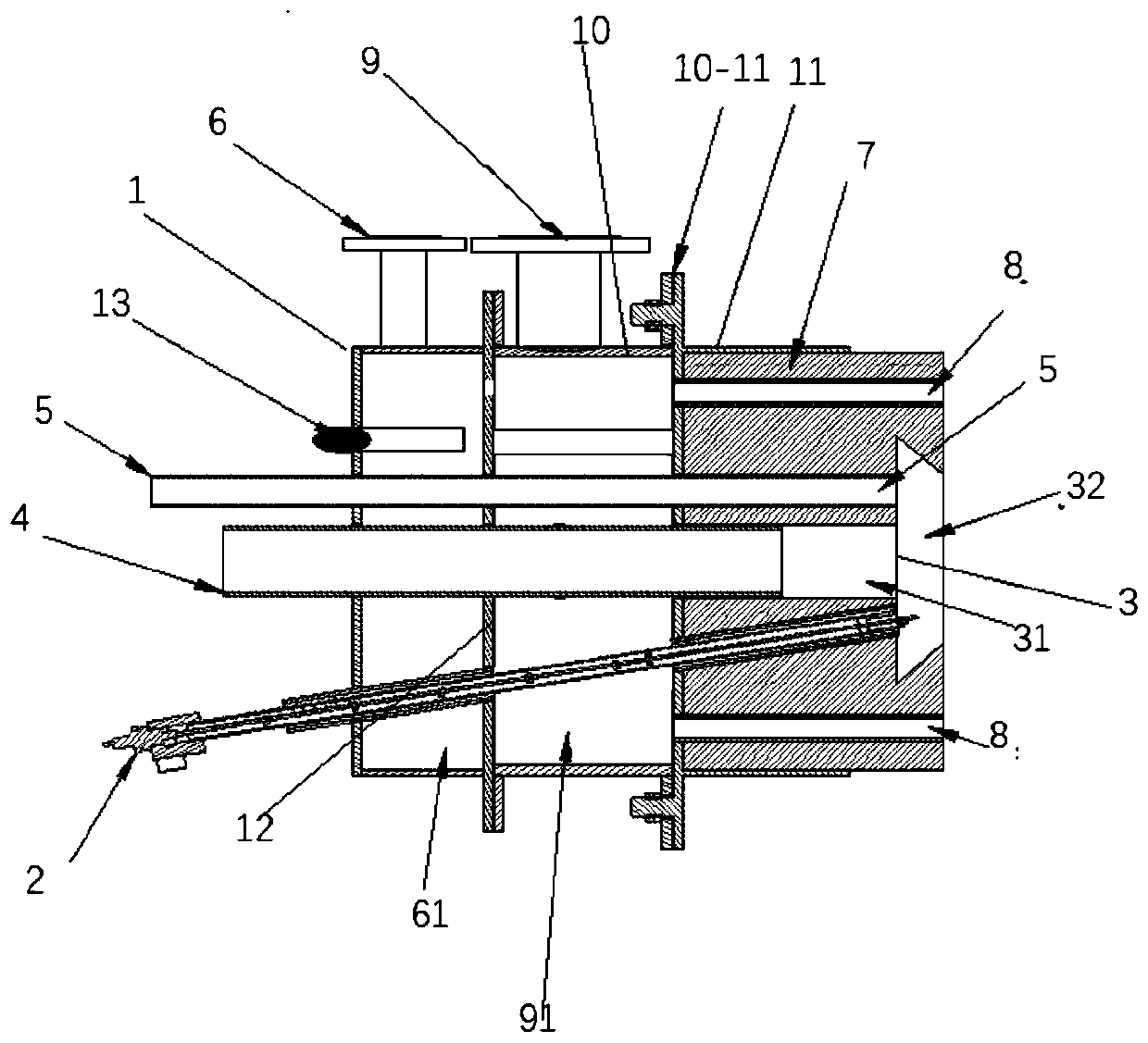

[0022] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

[0023] A multi-stage combustor. The multi-stage combustor 1 includes a burner body. The burner body is provided with an intake pipe for gas to enter; and the burner body is provided with a combustor for gas and oxygen combustion. Chamber 3; the combustion chamber 3 includes a combustion chamber nozzle 32, the combustion chamber nozzle 32 communicates with the outer side of the burner body; the burner body is provided with an ignition gun 2 for ignition; one end of the ignition gun 2 It is inside the burner body, and the other end extends to the combustion chamber 3; the intake pipe includes a gas intake pipe 4 and a flame-stabilized intake pipe 5; the gas intake pipe 4 and a flame-stabilized intake pipe 5 and the combustion chamber 3 is connected; the present invention discloses a multi-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com