Closed riser indirect evaporative cooling high temperature chiller

An evaporative cooling and chiller technology, which is used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as difficulty in meeting water quality control requirements, high water quality requirements, and limited applicability, and achieve reduced size. , The effect of reducing water temperature and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

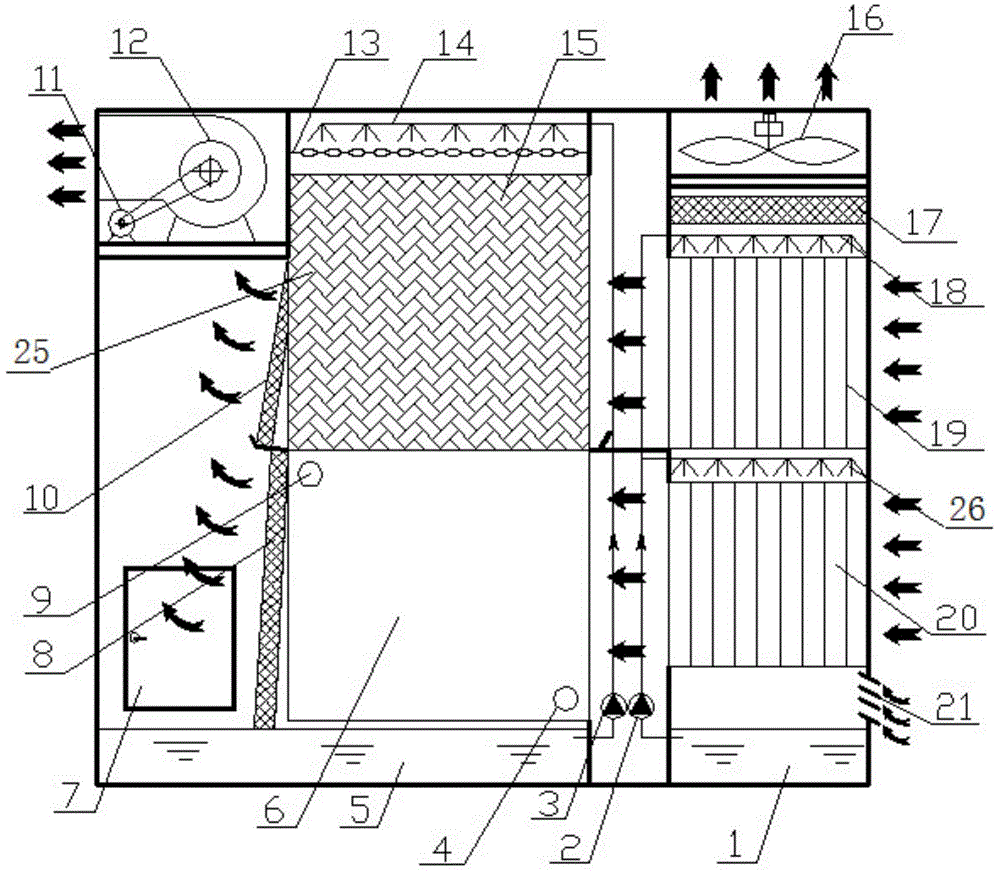

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

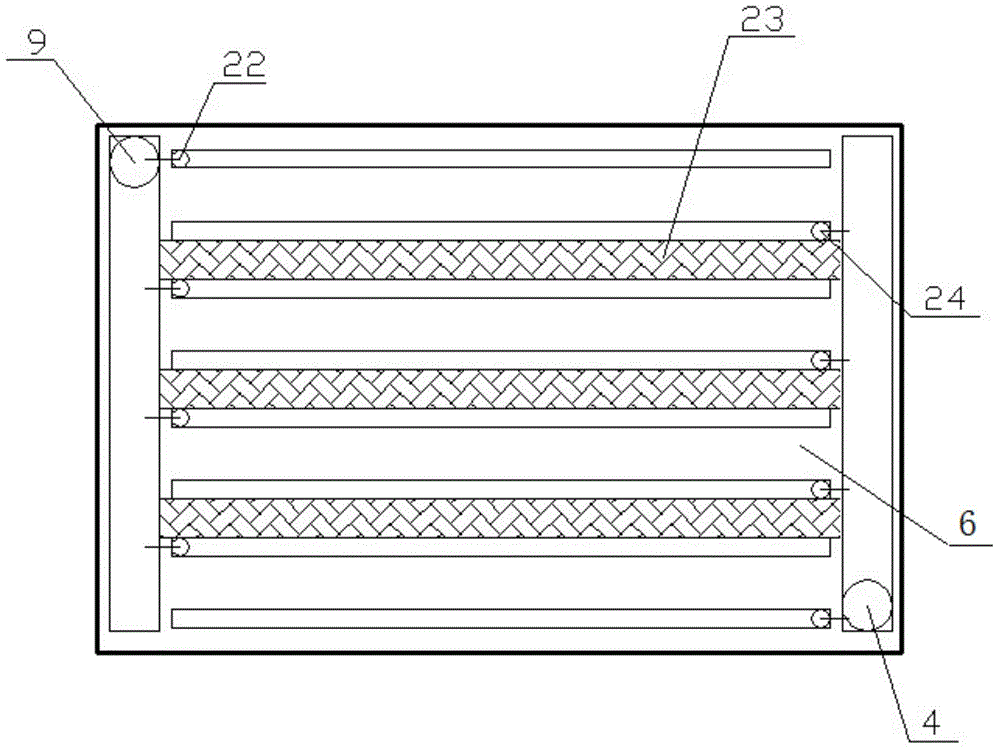

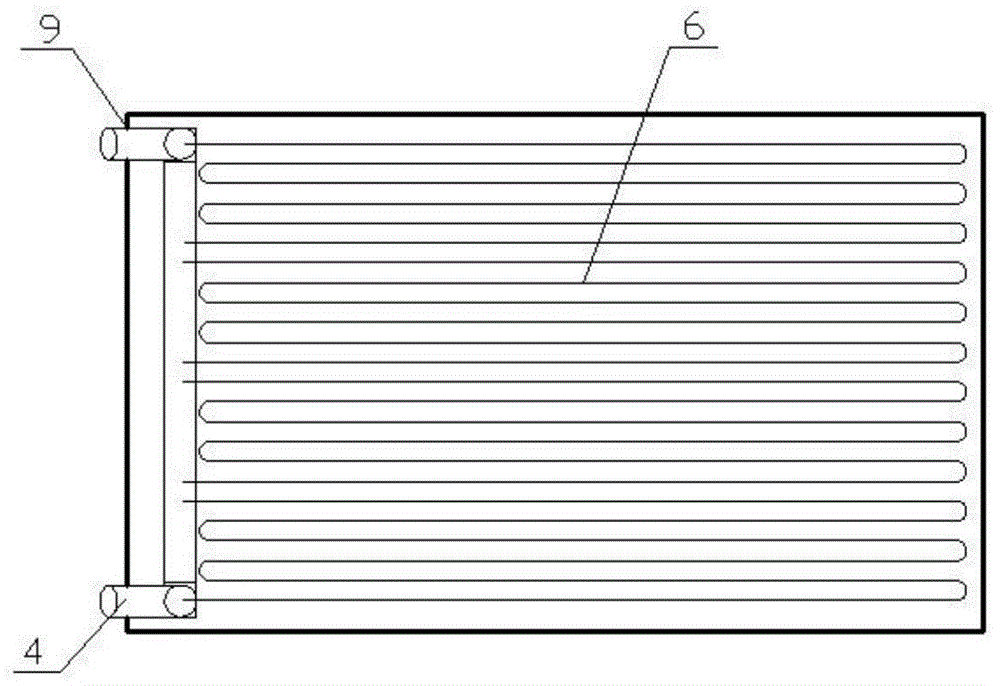

[0023] The structure of the high-temperature water chiller with closed standpipe indirect evaporative cooling of the present invention is as follows: figure 1 As shown, it includes vertical pipe indirect evaporative cooler a19 and vertical pipe indirect evaporative cooler b20 arranged up and down at the air inlet in the unit shell, and the lower part of vertical pipe indirect evaporative cooler b20 is the secondary air inlet 21 , according to the air inlet direction, a direct evaporative cooler 25, a water baffle b10 and a centrifugal fan 12 are arranged in turn behind the standpipe indirect evaporative cooler a19, and a closed cooling fan 12 is arranged in turn behind the standpipe indirect evaporative cooler b20. The heater 6, the water baffle a8, and the upper part of the vertical tube indirect evaporative cooler a19 are provided with a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com