Composite polarizing plate and TN mode liquid crystal panel

A composite polarization, liquid crystal panel technology, used in polarizing elements, synthetic resin layered products, instruments, etc., can solve the problems of reduced contrast, light leakage of the display screen, poor heat resistance, etc., and achieve the effect of suppressing dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

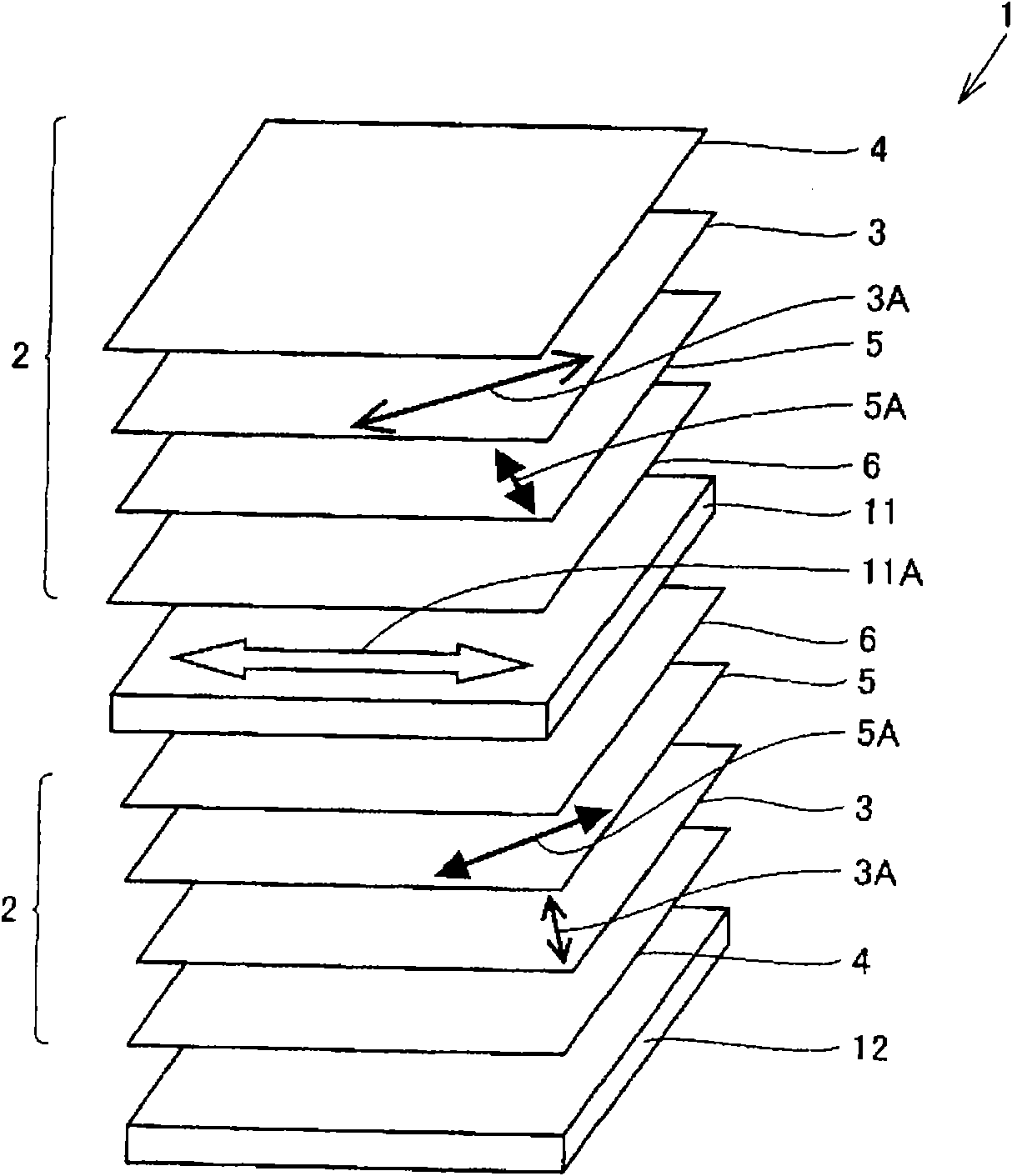

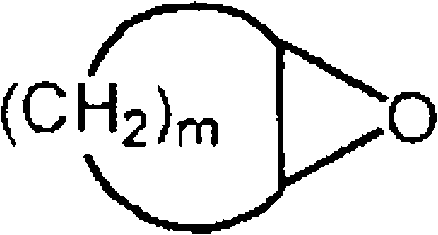

[0179] A cellulose triacetate film (KC8UX2MW, manufactured by Konica Minolta Co., Ltd., thickness: 80 μm) was placed on one side of a polarizer prepared by adsorbing and aligning iodine on polyvinyl alcohol, and a cyclic olefin film was placed on the opposite side. Retardation film made of resin-like resin (Zeonor film, manufactured by Japan Zeon Co., Ltd., R 0 : 80nm, R th : 110 nm, thickness: 40 μm) The absorption axis of the polarizing plate and the slow axis of the retardation film are made to be perpendicular to each other, and they are adhered with respective adhesives. At this time, after performing corona discharge treatment on the adhesive surface side of the phase difference film under the condition of a cumulative irradiation dose of 1680J, an epoxy-based ultraviolet curing Type adhesive for lamination with polarizers. Next, using an ultraviolet irradiation system (manufactured by Fusion UV Systems Co., Ltd.), ultraviolet rays were irradiated from the side of the ...

Embodiment 2

[0185] A composite polarizing plate was produced in the same manner as in Example 1, except that the triacetate cellulose film was replaced by a biaxially stretched polyethylene terephthalate film (thickness: 38 μm, haze: 2.3%). The amount of light leakage was evaluated using a TN-mode liquid crystal monitor composed of a TN-mode liquid crystal panel bonded with this composite polarizing plate, and it was 1.0 cd / m 2 .

Embodiment 3

[0201] (a) Fabrication of composite polarizing plate

[0202] On one side of a polarizer obtained by adsorbing and aligning iodine on polyvinyl alcohol, cellulose triacetate (KC8UX2MW, manufactured by Konica Minolta Co., Ltd.) with a thickness of 80 μm is placed as a transparent protective layer, and placed on the opposite side of the polarizer A retardation film with a thickness of about 40 μm made of cyclic olefin resin (obtained from Japan Zeon Co., Ltd.; R 0 =80nm, R th =110nm), to make a composite polarizing plate. At this time, corona discharge treatment is first performed on the adhesive surface side of the retardation film under the condition of a cumulative irradiation dose of 1680 J, and then the adhesive surface of the retardation film and the protective film made of triacetyl cellulose are bonded. The surface is coated with epoxy UV-curable adhesive respectively, and bonded with the polarizer. Next, ultraviolet rays were irradiated from the retardation film side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com