Novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification

A nickel-cobalt slag and zinc smelting technology, applied in the field of comprehensive recycling of nickel-cobalt slag, can solve problems such as environmental pollution, consumption, and no separation technology proposed, and achieve the effect of solving industry problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

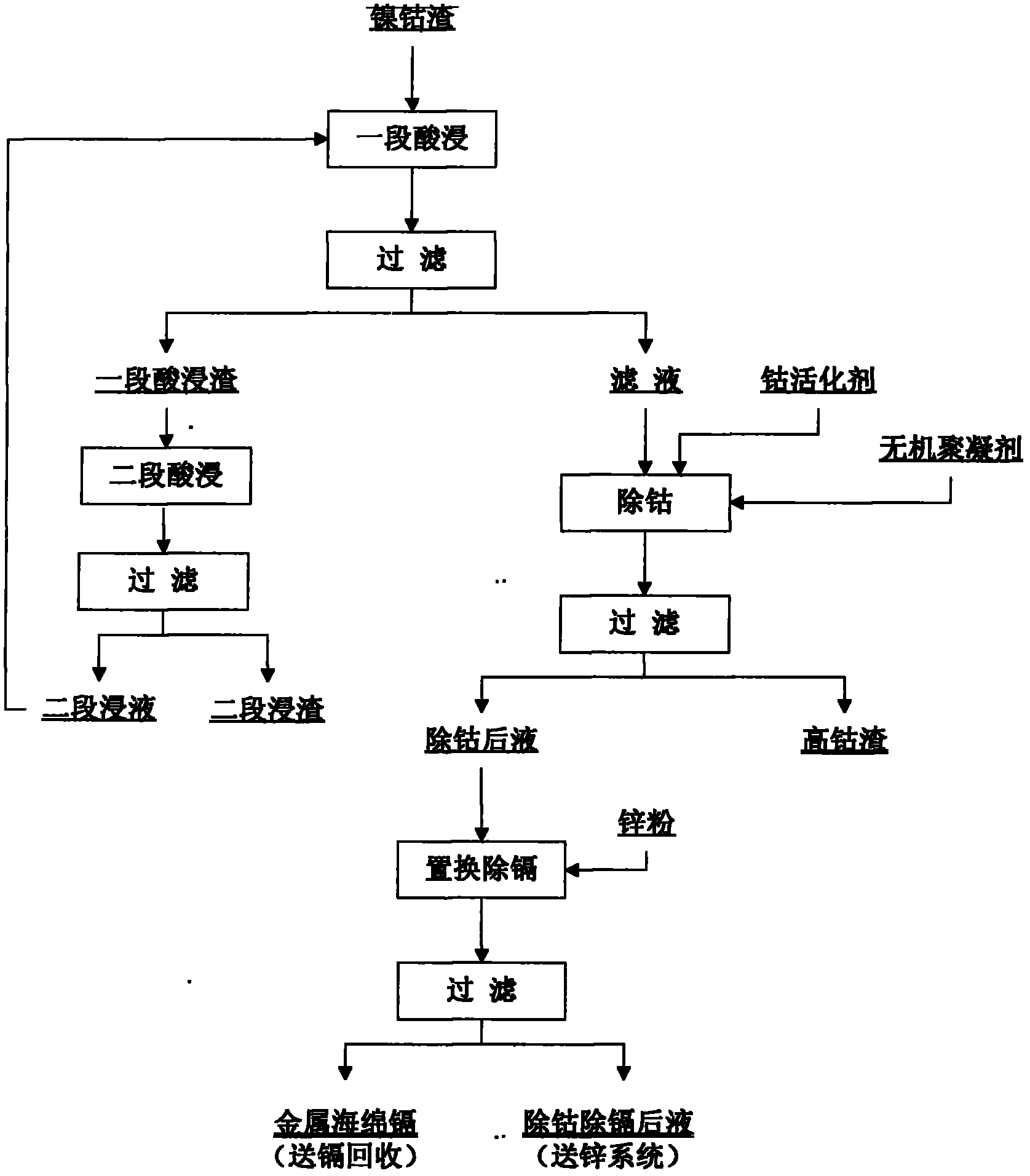

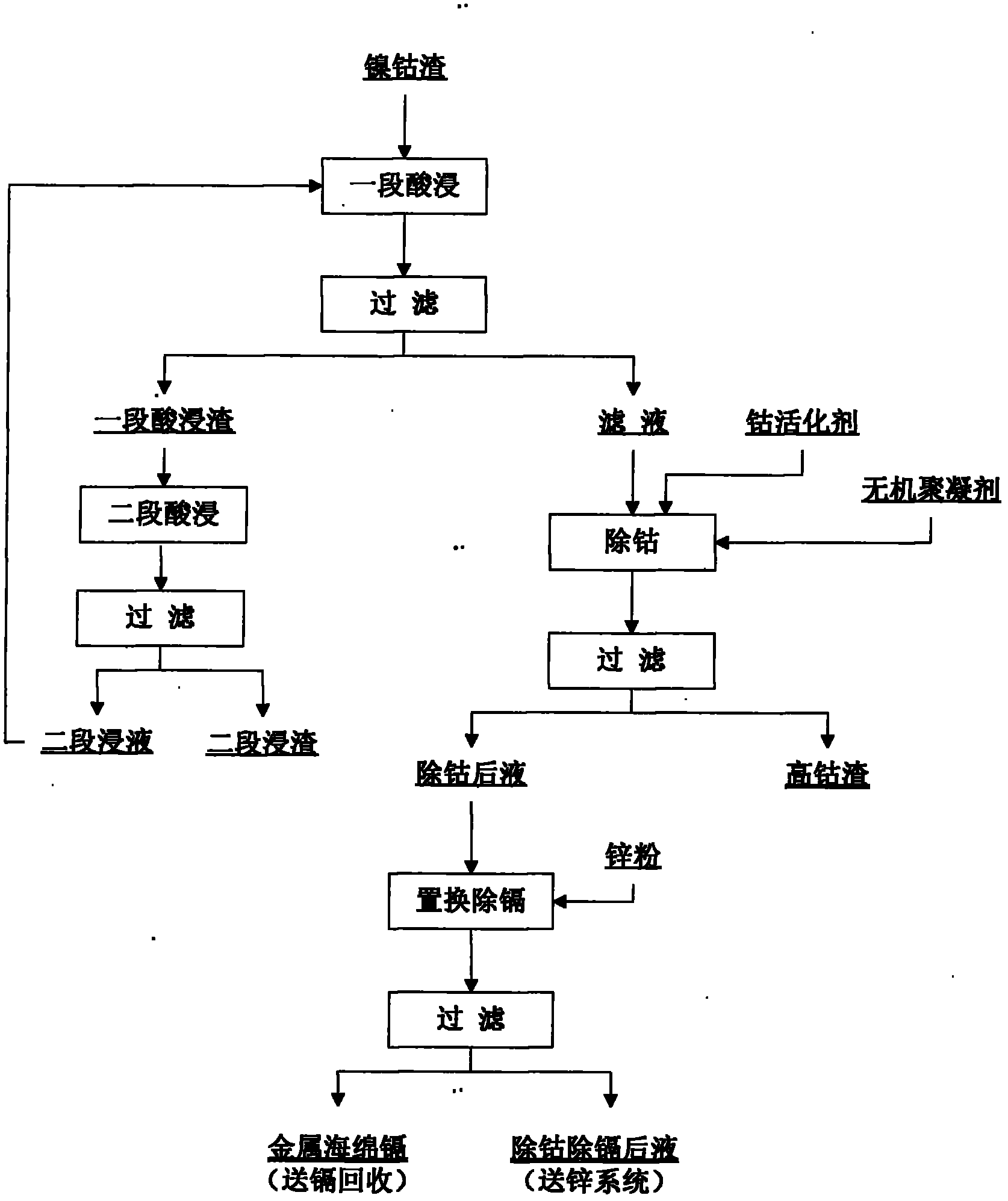

[0030] Example 1: see figure 1 , a new zinc-cobalt separation process for purifying nickel-cobalt slag produced in zinc smelting, the steps are:

[0031] (1) One-stage leaching: Slurry the nickel-cobalt slag with water and add it to the leaching tank. The leaching tank is equipped with a natural exhaust pipe, and then sulfuric acid is added. The initial concentration of sulfuric acid in the reaction solution is controlled at 120-130g / L. The solid ratio is 3 / 1, stirred, the heating temperature is 70-75°C, the reaction time is 110 minutes, and then filtered to obtain a section of leaching solution and a section of leaching residue;

[0032] (2) Second-stage leaching: Slurry the first-stage leaching residue with water and add it to the leaching tank. The leaching tank is equipped with a natural exhaust pipe, and then sulfuric acid is added. The initial concentration of sulfuric acid in the reaction solution is controlled at 195-200g / L. The liquid-solid ratio is 3 / 1, stirred, the...

Embodiment 2

[0043] Example 2: see figure 1 , a new zinc-cobalt separation process for purifying nickel-cobalt slag produced in zinc smelting, the steps are:

[0044] (1) One-stage leaching: Slurry the nickel-cobalt slag with water and add it to the leaching tank. The leaching tank is equipped with a natural exhaust pipe, and then sulfuric acid is added. The initial concentration of sulfuric acid in the reaction solution is controlled at 130-135g / L. The solid ratio is 4 / 1, stirred, the heating temperature is 75-80°C, the reaction time is 90 minutes, and then filtered to obtain a section of leaching solution and a section of leaching residue;

[0045] (2) Second-stage leaching: Slurry the first-stage leaching residue with water and add it to the leaching tank. The leaching tank is equipped with a natural exhaust pipe, and then sulfuric acid is added. The initial concentration of sulfuric acid in the reaction solution is controlled at 195-200g / L. The liquid-solid ratio is 4 / 1, stirring, the...

Embodiment 3

[0057] Embodiment 3: see figure 1 , step is the same as embodiment 2, but described activator is made up of following components by weight percentage: ZnO 33%, Na 2 o 2 32%, Na 2 SO 4 35%.

[0058] The inorganic coagulant consists of the following components by weight percentage: ZnCO 3 2Zn(OH) 2 ·H 2 O60%, NaOH 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com