Water injection method in cooking ball

A technology of steaming balls and clear water, applied in filament forming processing, textile and papermaking, fiber processing, etc., to achieve the effect of reducing the operating intensity of employees, reducing the time of pouring materials, and reducing the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

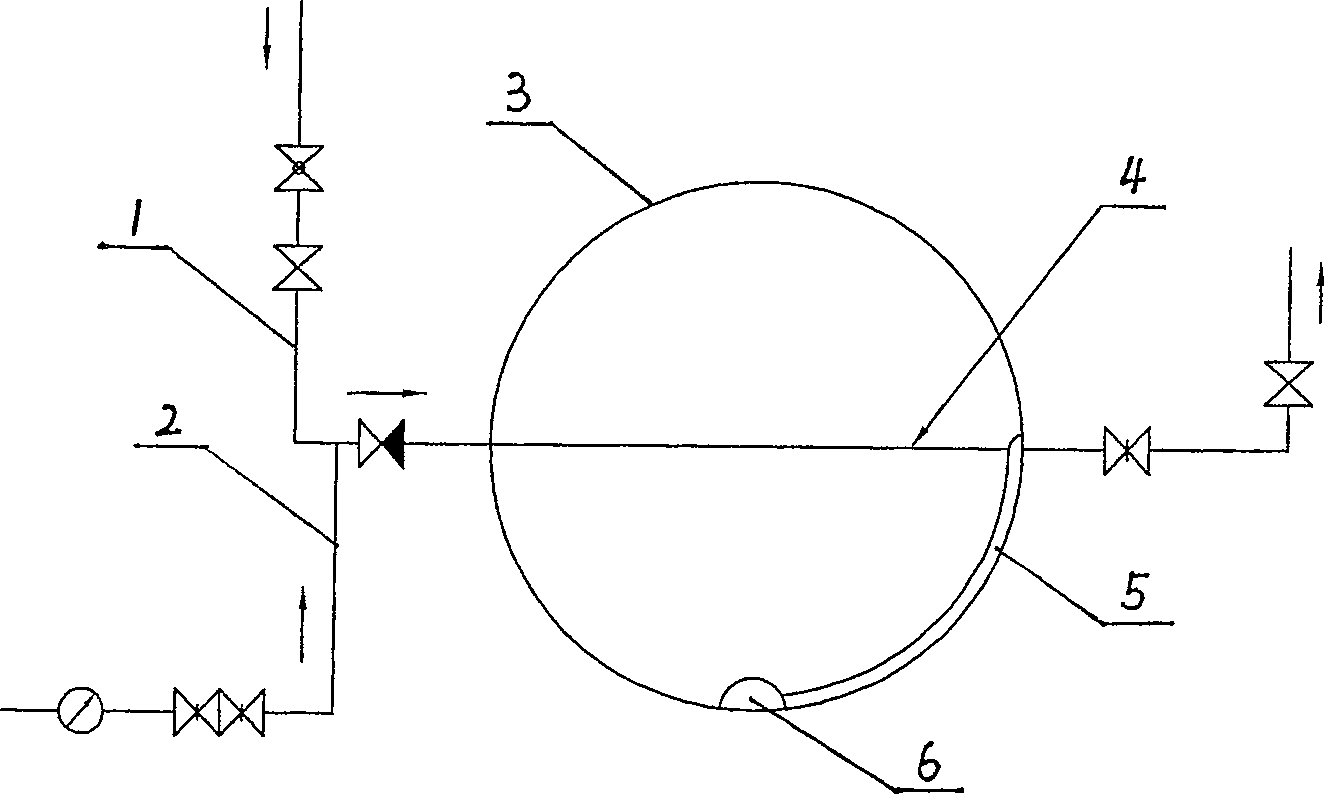

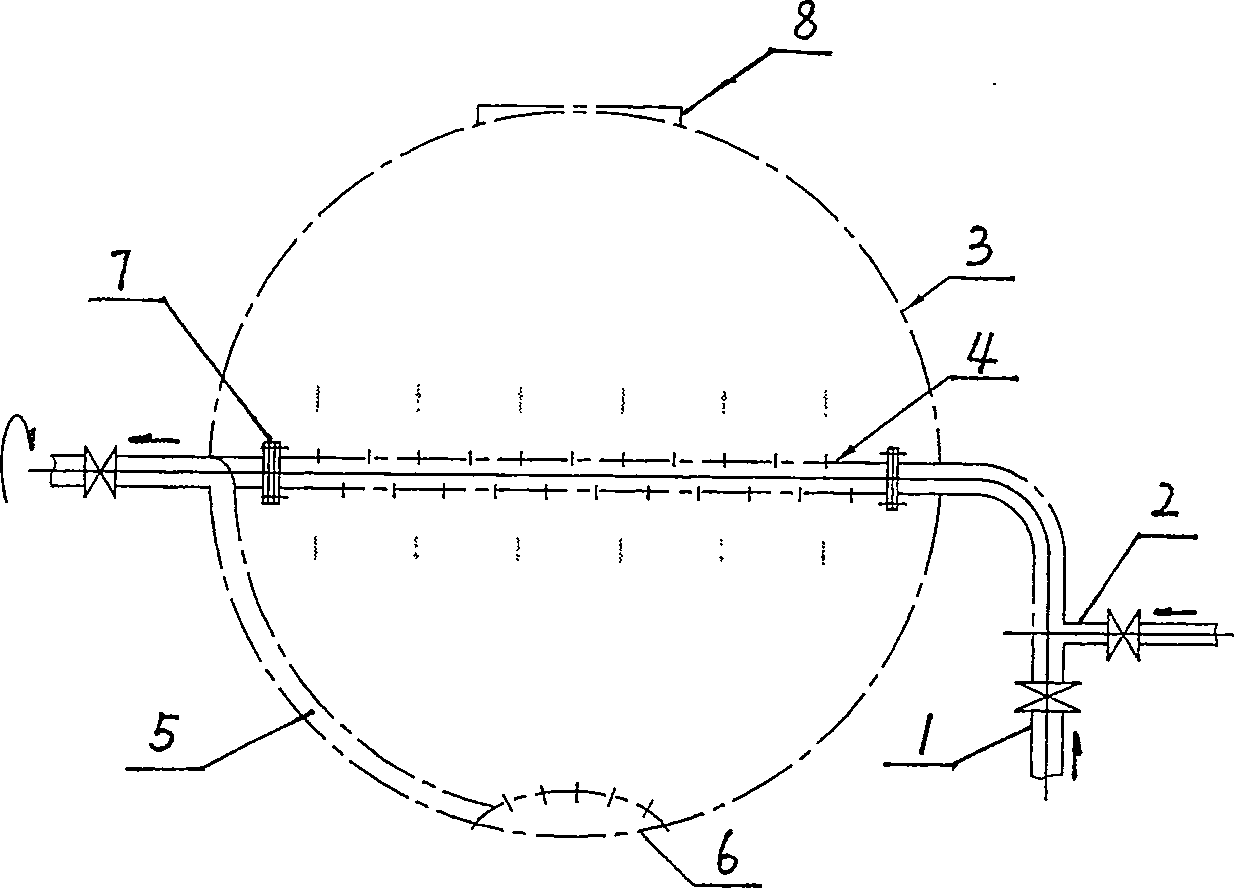

[0019] The water injection method in the steam ball is characterized in that: on the steam ball inlet pipe, a water inlet pipe 2 connected with the steam inlet pipe 1 is provided, and the steam inlet pipe 1 is also connected with the middle pipe 4 passing through the steam ball 3 , the pipe wall of the middle pipe 4 is provided with a plurality of through holes for steam or water, and the water injection steps are:

[0020] a. 5 minutes before the steaming ball 3 is poured, close the steam inlet pipe 1, open the water inlet pipe 2, and spray evenly into the steaming ball 3 into 4m through the steaming ball middle pipe 4 3 , Clear water with a temperature of about 14°C and a pressure of 2Kg;

[0021] b. Rotate the steaming ball 3, the steaming ball 3 drives the middle pipe 4 to rotate, and through the rotating process of the steaming ball 3, the clear water and the slurry in the ball are evenly mixed;

[0022] c. During the pouring process after the steaming ball is opened, co...

Embodiment 2

[0026] The water injection method in the steam ball is characterized in that: on the steam ball inlet pipe, a water inlet pipe 2 connected with the steam inlet pipe 1 is provided, and the steam inlet pipe 1 is also connected with the middle pipe 4 passing through the steam ball 3 , the pipe wall of the middle pipe 4 is provided with a plurality of through holes for steam or water, and the water injection steps are:

[0027] a. 5 minutes before the steaming ball 3 is poured, close the steam inlet pipe 1, open the water inlet pipe 2, and spray evenly into the steaming ball 3 into the steaming ball 3 through the steaming ball 4 3 , Clean water with a temperature of about 26°C and a pressure of 3Kg;

[0028] b. Rotate the steaming ball 3, the steaming ball 3 drives the middle pipe 4 to rotate, and through the rotating process of the steaming ball 3, the clear water and the slurry in the ball are evenly mixed;

[0029] c. During the pouring process after the steaming ball is opene...

Embodiment 3

[0031] The water injection method in the steam ball is characterized in that: on the steam ball inlet pipe, a water inlet pipe 2 connected with the steam inlet pipe 1 is provided, and the steam inlet pipe 1 is also connected with the middle pipe 4 passing through the steam ball 3 , the pipe wall of the middle pipe 4 is provided with a plurality of through holes for steam or water, and the water injection steps are:

[0032] a. 5 minutes before the steaming ball 3 is poured, close the steam inlet pipe 1, open the water inlet pipe 2, and spray evenly into the steaming ball 3 into the steaming ball 3 through the steaming ball 4 3 , Clear water with a temperature of about 20°C and a pressure of 4Kg;

[0033] b. Rotate the steaming ball 3, the steaming ball 3 drives the middle pipe 4 to rotate, and through the rotating process of the steaming ball 3, the clear water and the slurry in the ball are evenly mixed;

[0034] c. During the pouring process after the steaming ball is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com