Comprehensive recovery process for polymetallic arsenic-containing soot

A multi-metal and soot technology, applied in the direction of improving process efficiency, can solve problems such as hidden pollution, unreasonable economic technology, sulfur dioxide flue gas pollution, etc., and achieve the effect of eliminating the impact of environmental pollution, improving economic benefits, and cleaning the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

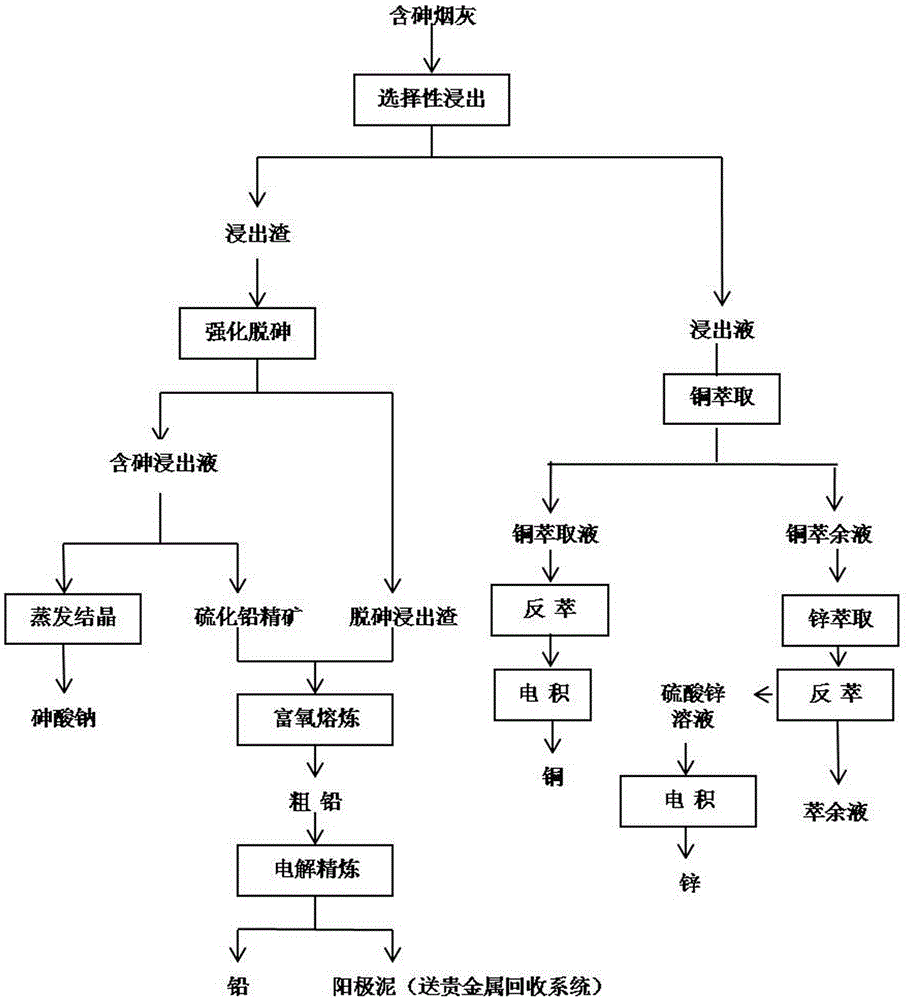

[0024] Arsenic-containing soot polymetallic comprehensive recovery process, the specific steps are:

[0025] (1) Selective leaching: Slurry 10kg of arsenic-containing soot with water and add it to the leaching tank, then add the leaching agent and stir. The leaching agent is an aqueous solution with an initial mass fraction of 10%, and the liquid-solid weight ratio is 2:1 , the leaching temperature is 35°C, the leaching time is 4 hours, and filtered to obtain the leaching solution and leaching residue;

[0026] The solute components and weight ratio of the leaching agent are:

[0027] (NH 4 ) 2 SO 4 :65%, MnO 2 : 15%, H 2 o 2 : 20%;

[0028] (2) Extraction, back-extraction and electrowinning: In step (1), the leaching solution is firstly extracted with LIX841 and 260# kerosene mixed organic phase to extract copper, the extraction ratio is 2:1, the extraction temperature is 40°C, and the clarification time is 5min, and the organic phase is used 150-200g / L sulfuric acid ...

Embodiment 2

[0035] The arsenic-containing soot from a domestic non-ferrous metal smelting enterprise is selected. The important metal components and their mass fractions or contents are: Cu8%, Pb36%, Zn12%, As9%, In0.022%, Bi2.86%, Au0.8g / t, Ag126g / t.

[0036] (1) Selective leaching: Slurry 10kg of the above-mentioned arsenic-containing soot into the leaching tank, then add the leaching agent, stir, the initial mass fraction of the leaching agent is 15%, and the liquid-solid weight ratio is 3:1. The temperature is 35°C, the leaching time is 4 hours, and the leaching solution and leaching residue are obtained by filtering;

[0037] The composition and weight ratio of the leaching agent are:

[0038] (NH 4 ) 2 SO 4 :50%, MnO 2 : 20%, H 2 o 2 : 30%;

[0039] (2) Extraction, stripping and electrowinning: in step (1), the leaching solution is firstly extracted with LIX841 and 260# kerosene mixed organic phase to extract copper, the extraction ratio is 2:1, the extraction temperature is ...

Embodiment 3

[0047] Embodiment 3: the composition and weight proportion of leaching agent are: (NH 4 ) 2 SO 4 :40%, MnO 2 : 35%, H 2 o 2 : 25%; the solute component and weight ratio of the mixed arsenic removal agent are: H 2 o 2 : 45%, Na 2 S 2 o 3 : 55%. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com