Method for preparing tungsten carbide nano-powder

A tungsten carbide nano and tungsten nitride powder technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of large WC grains, cumbersome process, high energy consumption, etc., to reduce the cost of raw materials and Energy consumption, cheap and easy-to-obtain raw materials, and the effect of reducing synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

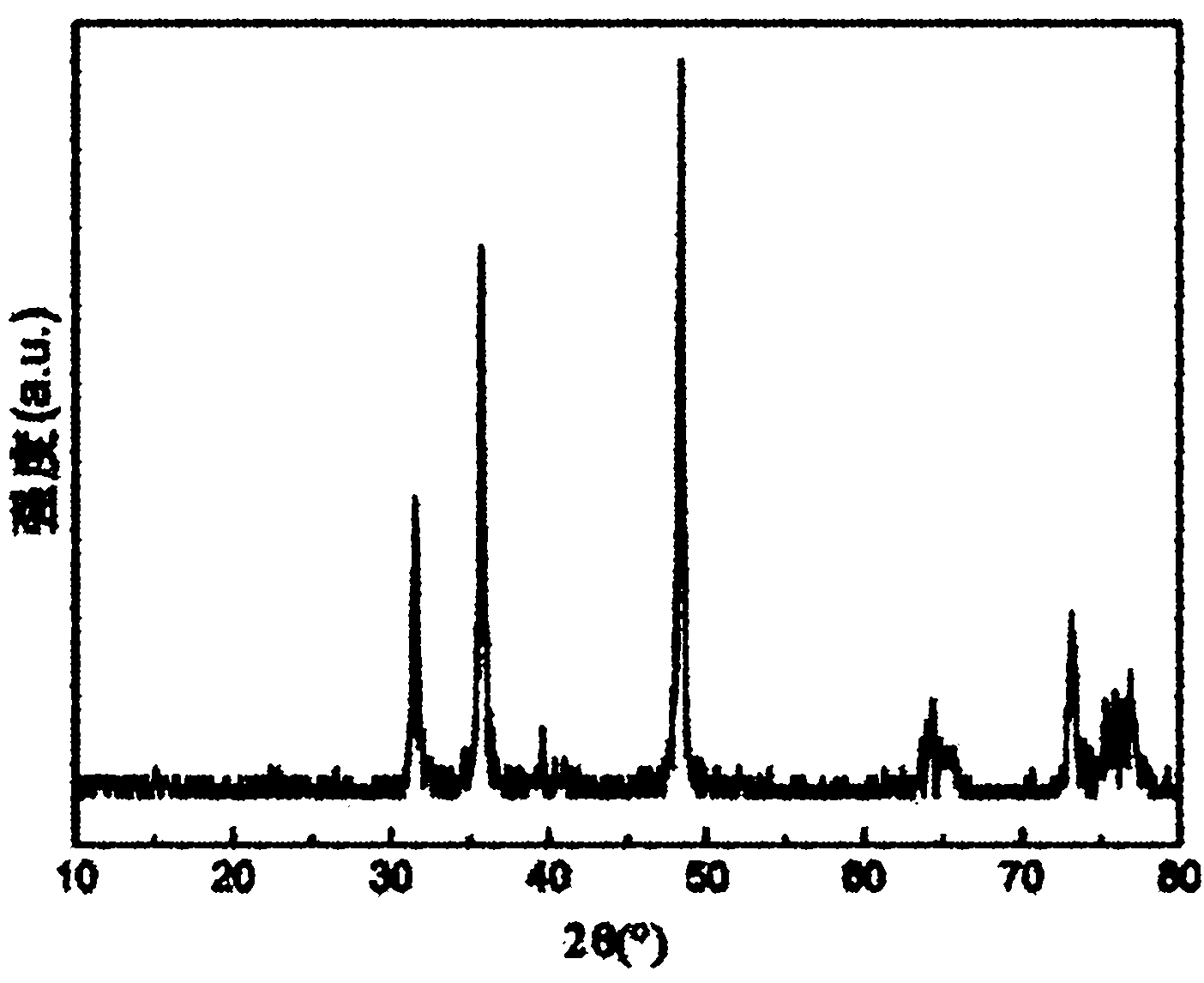

[0031] Weigh 10mmol of ammonium metatungstate and 50mmol of citric acid, dissolve them in 100ml of deionized water to obtain a clear mixed solution; perform complexation reaction in a water bath at 70°C for 5 hours; filter and dry at 120°C for 12 hours to obtain a tungsten oxide precursor body; calcined at 650°C for 3 hours in an air atmosphere to obtain WO 3 Powder.

[0032] The above WO 3 The powder is placed in a tube furnace, nitrogenated with ammonia gas, the flow rate of ammonia gas is controlled at 3L / min, the temperature is 700°C, the heating rate is 2°C / min, and the temperature is kept for 2 hours to obtain W 2 N powder.

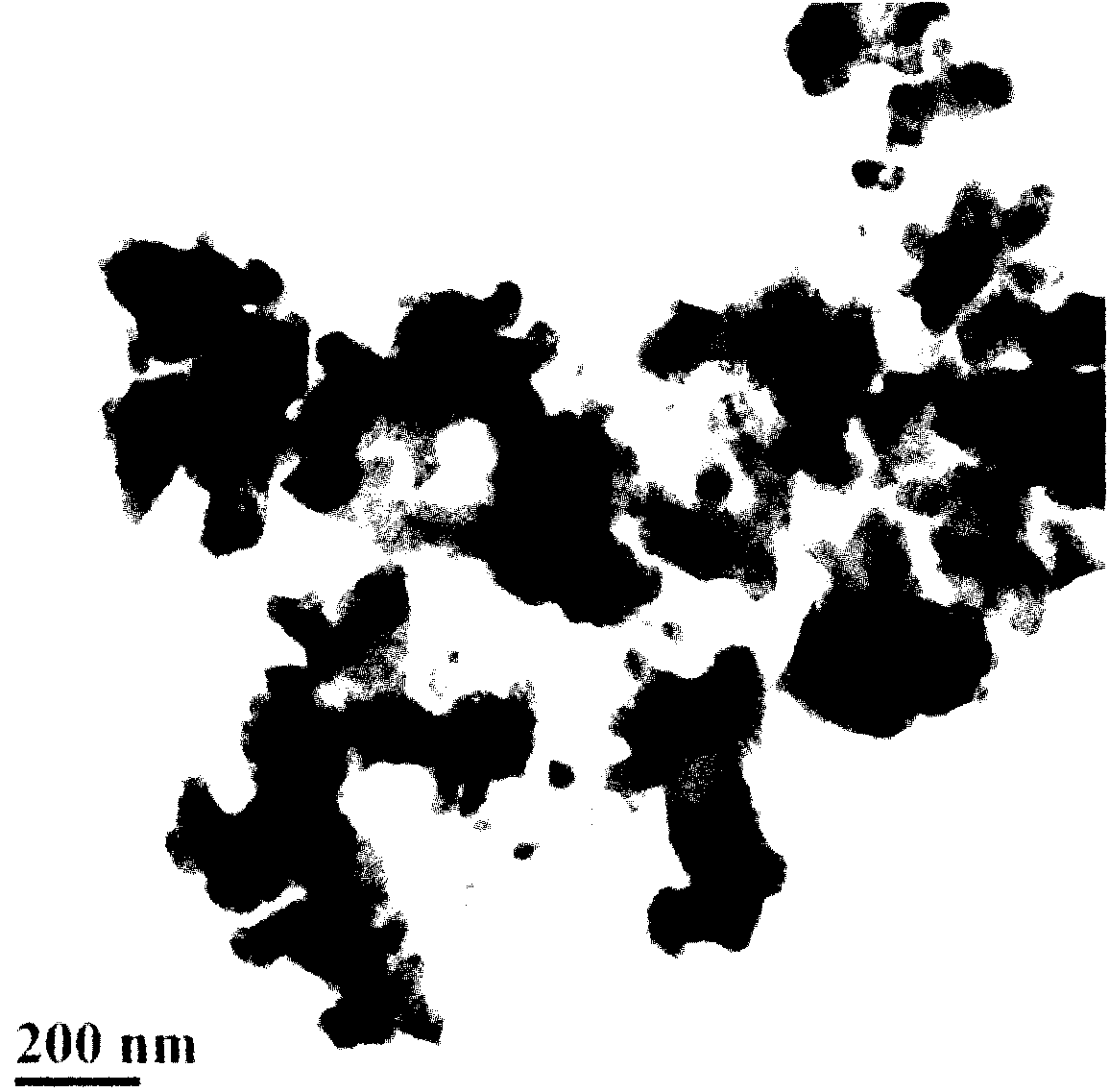

[0033] Mix 10 grams of the obtained tungsten nitride powder with 0.62 g of carbon black, use ethanol as a solvent and tungsten carbide balls as a ball milling medium, mix on a roller ball mill for 24 hours, and dry by rotary evaporation to obtain W 2 N / C mixed powder, W 2 The N / C mixed powder is placed in a graphite crucible, heated to 1100°C in...

Embodiment 2

[0038] The difference between this example and Example 1 is that the obtained tungsten nitride powder is directly placed in a tube furnace, and then carbonized with a mixed gas of methane and hydrogen, and the volume ratio of methane to hydrogen is 1: 8. The flow rate of the mixed gas is 200ml / min, the carbonization temperature is 850°C, and the carbonization time is 3 hours, and the WC nanopowder is obtained with an average particle size of 40nm.

[0039] The rest of the content is exactly the same as described in Example 1.

[0040] The WC nano-powder prepared in this example was sintered by hot pressing at 1600-1700° C. / 1 h and 25 MPa, and the relative density was higher than 97%, indicating that the prepared WC nano-powder had good sintering activity.

Embodiment 3

[0042] The difference between this example and Example 1 is that: mix 10 grams of the obtained tungsten nitride powder with 0.62 g of carbon black, put them in a mixing tank, use ethanol as a solvent, and tungsten carbide balls as a ball milling medium , mixed on a roller mill for 24 hours, and then dried by rotary evaporation to obtain W 2 N / C mixed dry powder, W 2The N / C mixed dry powder is placed in a graphite crucible, and nitrogen gas is introduced into the sintering furnace, and the reactant is heated to 1200°C and kept for 2 hours to obtain WC nano-powder with an average particle size of 150nm.

[0043] The rest of the content is exactly the same as described in Example 1.

[0044] The WC nano-powder prepared in this example was sintered by hot pressing at 1600-1700° C. / 1 h and 25 MPa, and the relative density was higher than 97%, indicating that the prepared WC nano-powder had good sintering activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com