Method for separating and purifying microcystin by utilizing series-connected solid phase extraction columns

A tandem solid-phase extraction and microcystin technology, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of inability to continue, many separation and purification steps, and large loss of toxins, so as to save costs. , low cost, the effect of saving organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

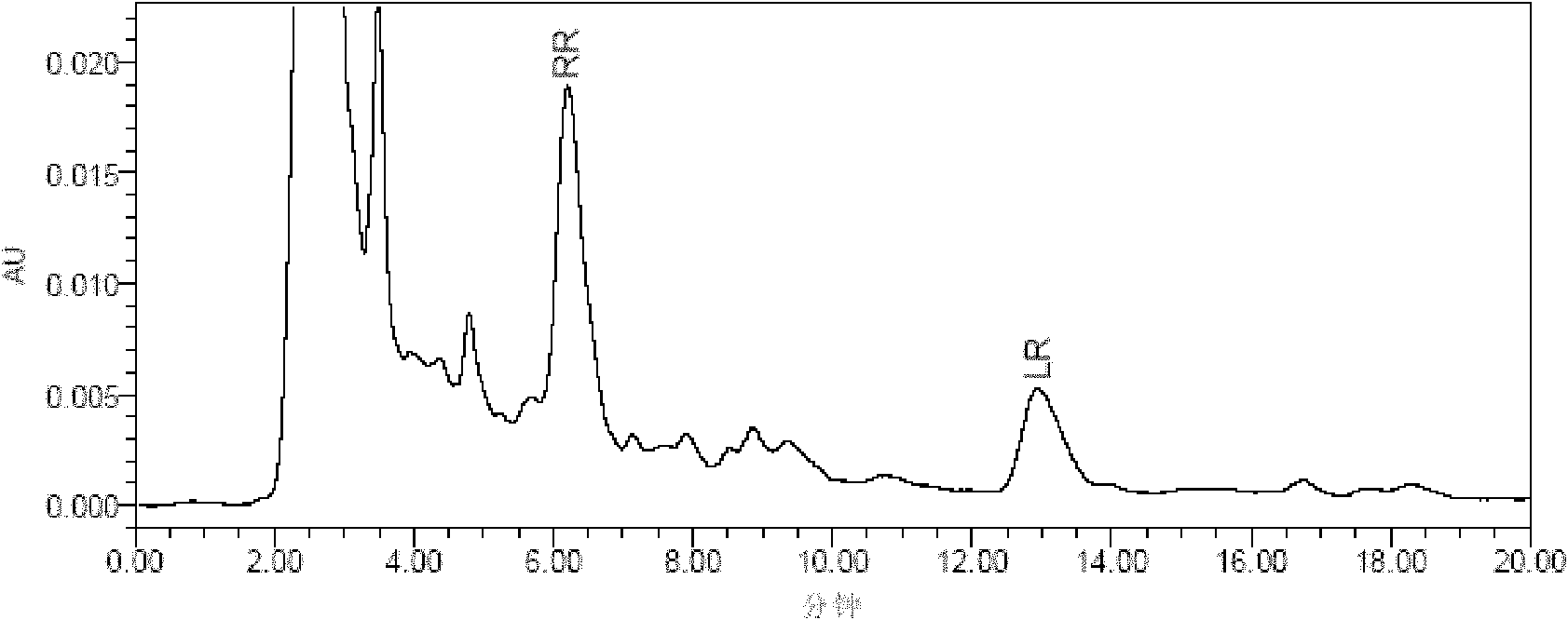

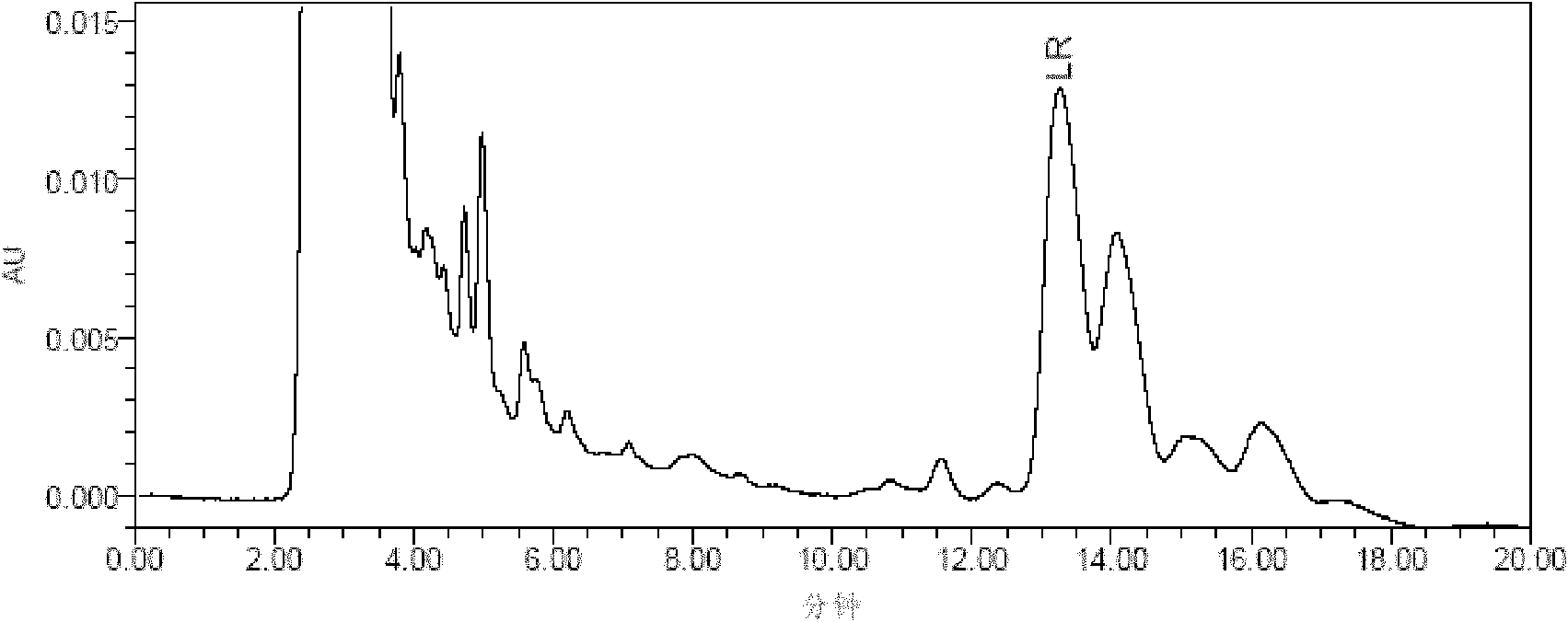

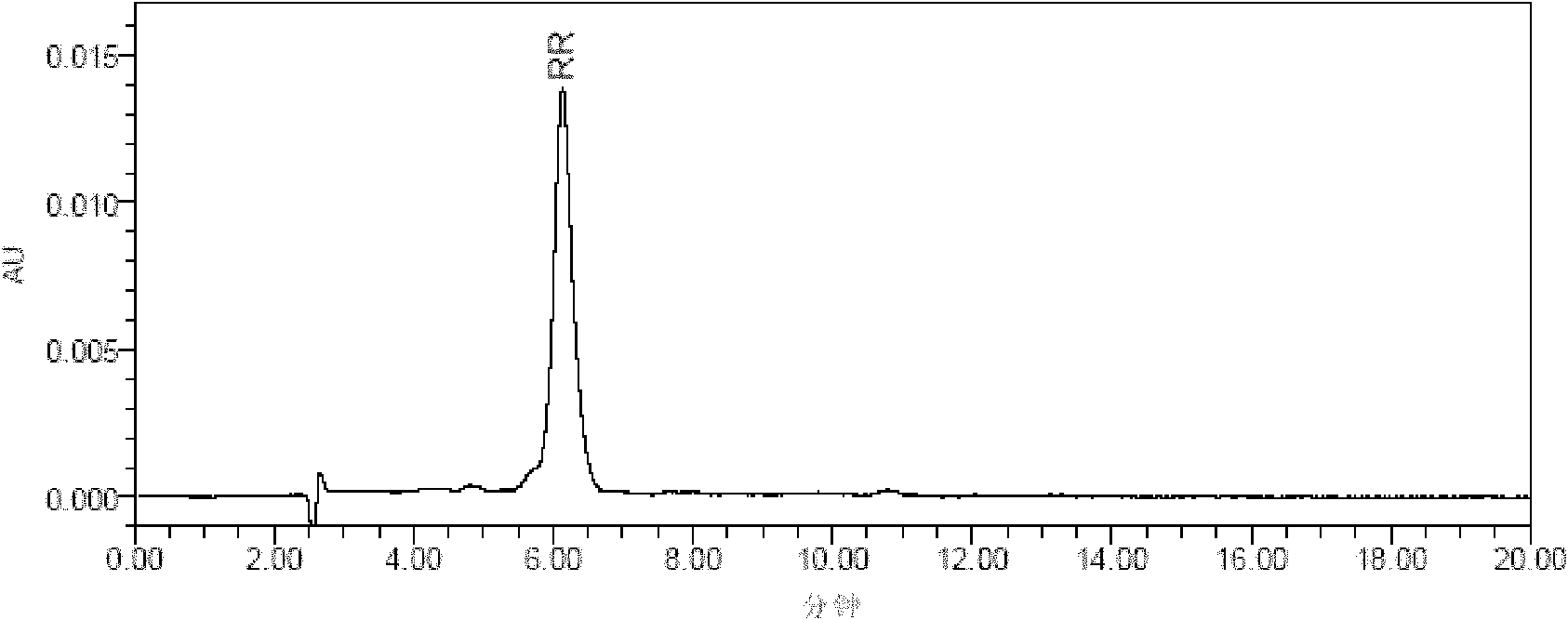

Image

Examples

Embodiment Construction

[0032] A method for separating and purifying microcystins by means of a tandem solid-phase extraction column, the steps of which are as follows:

[0033] 1. Algae powder material: Harvested wild cyanobacteria or indoor cultured Microcystis aeruginosa ( Microcystis aeruginosa ), freeze-dried to make dry algae powder, and stored at -20 oC.

[0034] 2. Preparation of solid phase extraction (SPE) cartridges: In an SPE column (10 mL, inner diameter 15 mm), load 1 g of C18 filler (15-35 μm, ODS or Sunchrom spherical silica gel, Beijing Jinouya Science and Technology Development Co., Ltd. company), press it with gaskets and save it for later use. The SPE column was activated with 30 mL methanol and 30 mL water before use. The series connection of the SPE column is connected by a stainless steel needle pierced rubber stopper. The ratio of the filler weight (0.5 or 1.0 or 1.5 or 2 g) of the first SPE cartridge to the weight of the algae flour to be treated is 1:10 to 1:40.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com