Recycling method for copper indium gallium selenide (CIGS) waste

A copper indium gallium selenide and recovery method technology, which is applied in the field of metal-nonmetal mixed waste recycling, can solve the problems of large environmental pollution, incomplete, complex and dangerous operations, etc., and achieve high environmental friendliness, easy large-scale production, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

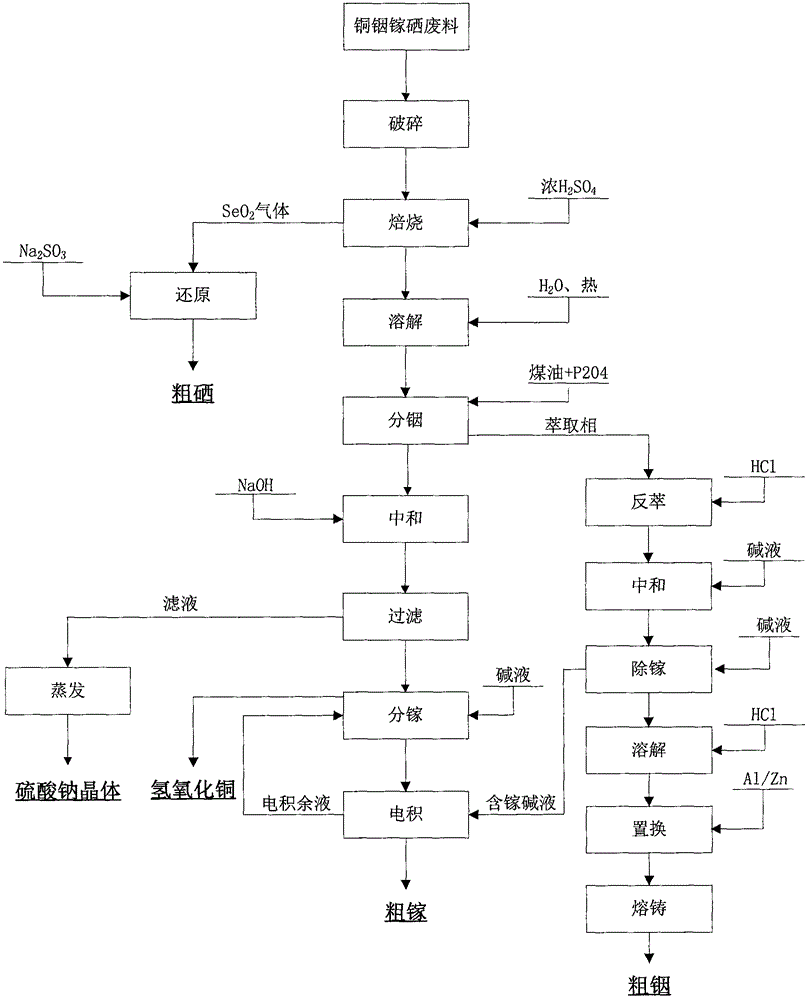

Image

Examples

Embodiment 1

[0047] Follow the steps below to recycle copper indium gallium selenide waste:

[0048] a. Milling: Crushing copper indium gallium selenide waste into powder with a particle size of 70-90 mesh;

[0049] b. Separation of selenium: add concentrated sulfuric acid to the powder and stir evenly, wherein the consumption of concentrated sulfuric acid is based on the basic requirement that the powder can be completely dissolved. Preferably, the mass ratio of the concentrated sulfuric acid to the powder is (1.0~1.8): 1, Then roast under negative pressure and 320°C. The specific pressure of roasting is based on the basic requirement of controlling the roasting furnace not to emit smoke, so as to obtain CuSO 4 、In 2 (SO 4 ) 3 , Ga 2 (SO 4 ) 3 Mixed sulfate and volatile SeO 2 gas, then Na 2 SO 3 solution to reduce the SeO 2 The gas gets crude selenium;

[0050] c. Dissolving: heating and dissolving the mixed sulfate with water to obtain a solution with an indium ion concentrati...

Embodiment 2

[0056] Follow the steps below to recycle copper indium gallium selenide waste:

[0057] a. Milling: Crushing copper indium gallium selenide waste into powder with a particle size of 70-90 mesh;

[0058] b. Separation of selenium: add concentrated sulfuric acid to the powder and stir evenly, wherein the consumption of concentrated sulfuric acid is based on the basic requirement that the powder can be completely dissolved. Preferably, the mass ratio of the concentrated sulfuric acid to the powder is (1.0~1.8): 1, Roasting at negative pressure and 400 ° C, the specific pressure of the roasting is based on the basic requirement of controlling the roasting furnace not to emit smoke, and CuSO 4 、In 2 (SO 4 ) 3 , Ga 2 (SO 4 ) 3 Mixed sulfate and volatile SeO 2 gas, then Na 2 SO 3 solution to reduce the SeO 2 The gas gets crude selenium;

[0059] c. Dissolving: heating and dissolving the mixed sulfate with water to obtain a solution with an indium ion concentration of 3 to ...

Embodiment 3

[0065] Follow the steps below to recycle copper indium gallium selenide waste:

[0066] a. Milling: Crushing copper indium gallium selenide waste into powder with a particle size of 70-90 mesh;

[0067] b. Separation of selenium: add concentrated sulfuric acid to the powder and stir evenly, wherein the consumption of concentrated sulfuric acid is based on the basic requirement that the powder can be completely dissolved. Preferably, the mass ratio of the concentrated sulfuric acid to the powder is (1.0~1.8): 1, Roasting under negative pressure and 500 ° C, the specific pressure of the roasting is based on the basic requirement of controlling the roasting furnace not to emit smoke, and CuSO 4 、In 2 (SO 4 ) 3 , Ga 2 (SO 4 ) 3 Mixed sulfate and volatile SeO 2 gas, then Na 2 SO 3 solution to reduce the SeO 2 The gas gets crude selenium;

[0068] c. Dissolving: heating and dissolving the mixed sulfate with water to obtain a solution with an indium ion concentration of 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com