A neutralization and concentration device and method for use in the production of monoammonium phosphate

A monoammonium phosphate, production process technology, applied in the direction of phosphate, phosphorus oxyacid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

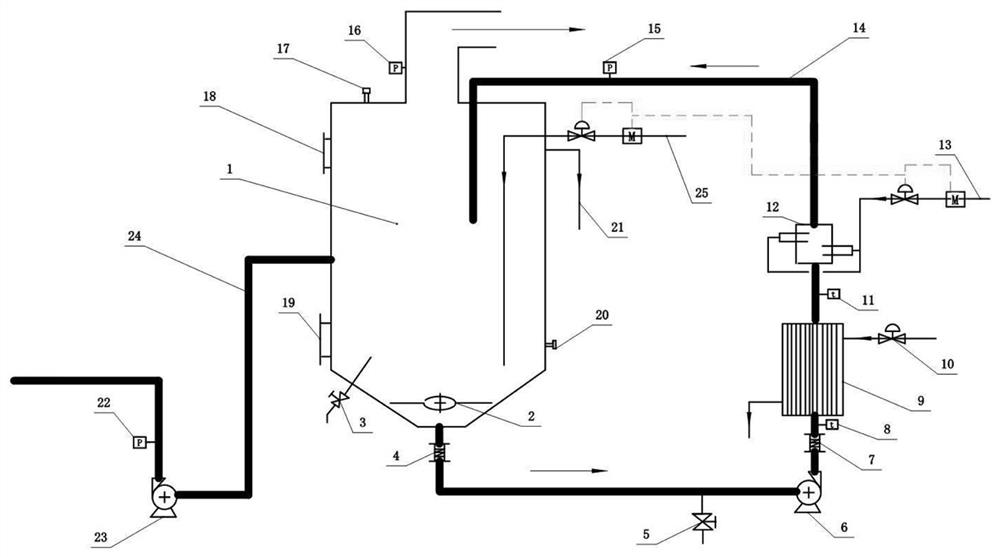

[0025] Such as figure 1 In connection with the drawings, the present invention is further explained:

[0026] A neutralization and concentrated apparatus for a ammonium phosphate produced, and the reactor 1 is connected to the steam heat exchanger 9, and the steam heat exchanger 9 is connected to the tube reactor 12, and the tube reactor 12 is reacted. The slurry circulation tube 14 is connected to the top of the reactor 1; the upper portion of the reactor 1 is provided with a sucked acid delivery tube 25; the middle of the reactor 1 is transmitted to the high pressure pump conveying tube 24 and the high pressure pump 23 is connected to the powder tower. .

[0027] The upper portion of the reactor 1 is provided with an overflow tube 21, and the overflow tube 21 is disposed at 80-90% levels of the reactor 1 tower body. The overflow tube 21 is open higher than the slurry to high pressure pump conveying tube 24 The insertion of the feeder is inserted into the lower portion 1 / 4-1 / 5 of...

Embodiment 2

[0032] The process carried out using the apparatus described in Example 1 is as follows:

[0033] 40-44% acid concentrated acid was delivered to the reactor tower body 1 by the intravation of the saueric acid delivery conduit 25, and the liquid level gauge 17 showed the liquid level to start the circulation pump 6;

[0034] Through the intravation of the intake gas ammonia to the tubular reactor 12, the sampling analysis is enhanced, and the induction of 0.92 mol / mol is reached. Automatic interlocking, set the amino ratio in the neutralization of 0.95 to 1.02 mol / mol;

[0035] When sampling analysis slurry, the specific gravity is 1.5-1.55, it is not necessary to use itself to concentrate steam heat exchanger 9; directly activate the high pressure pump 23 to transport the slurry to the powder tower, if the specific weight is less than 1.5, turn on the steam valve 10 to use The steam heat exchanger 9 is concentrated, and it is appropriately raised the rare acid or concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com