Centrifugal casting process for shell of bimetal compound metallurgical wedge hob

A centrifugal casting and bimetal technology, which is applied in the field of mining machinery and equipment, can solve the problems of difficult control of precision, low processing efficiency, high processing cost, etc., to meet the requirements of rigidity and easy processing, improve service life, and meet the requirements of strength and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

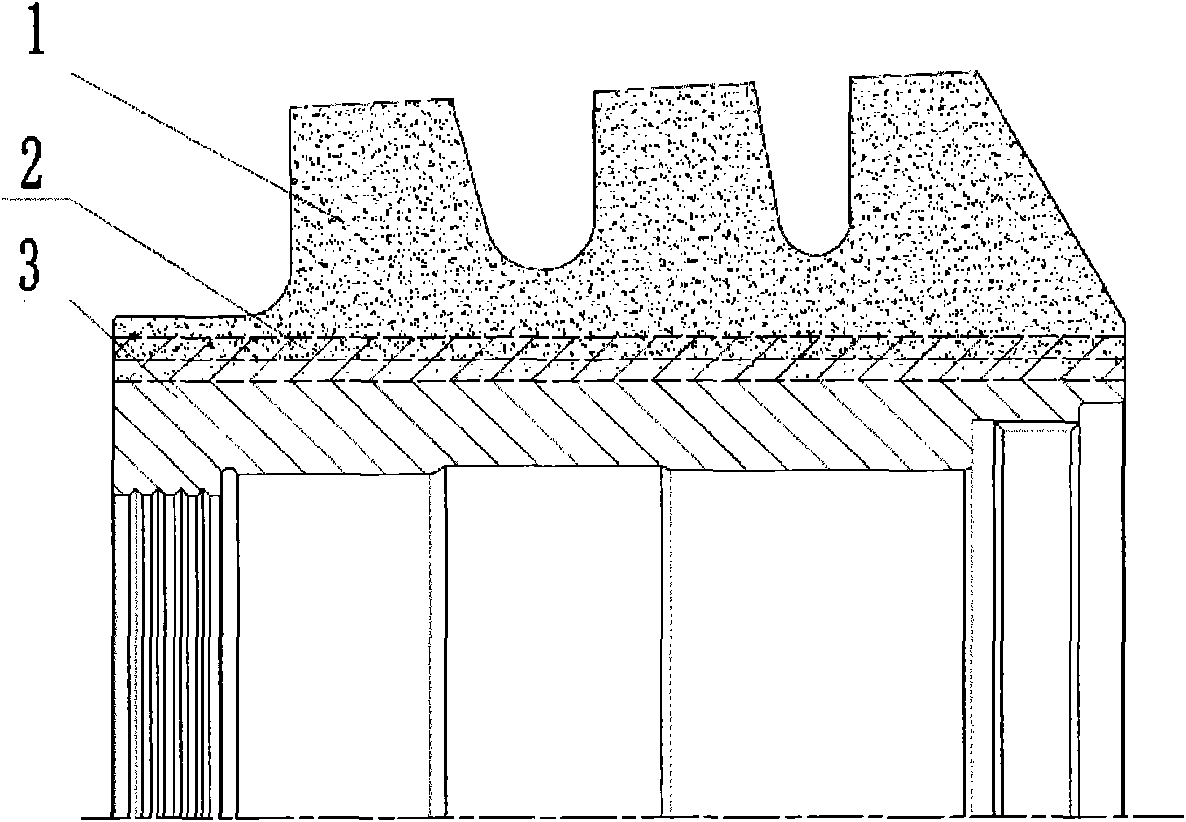

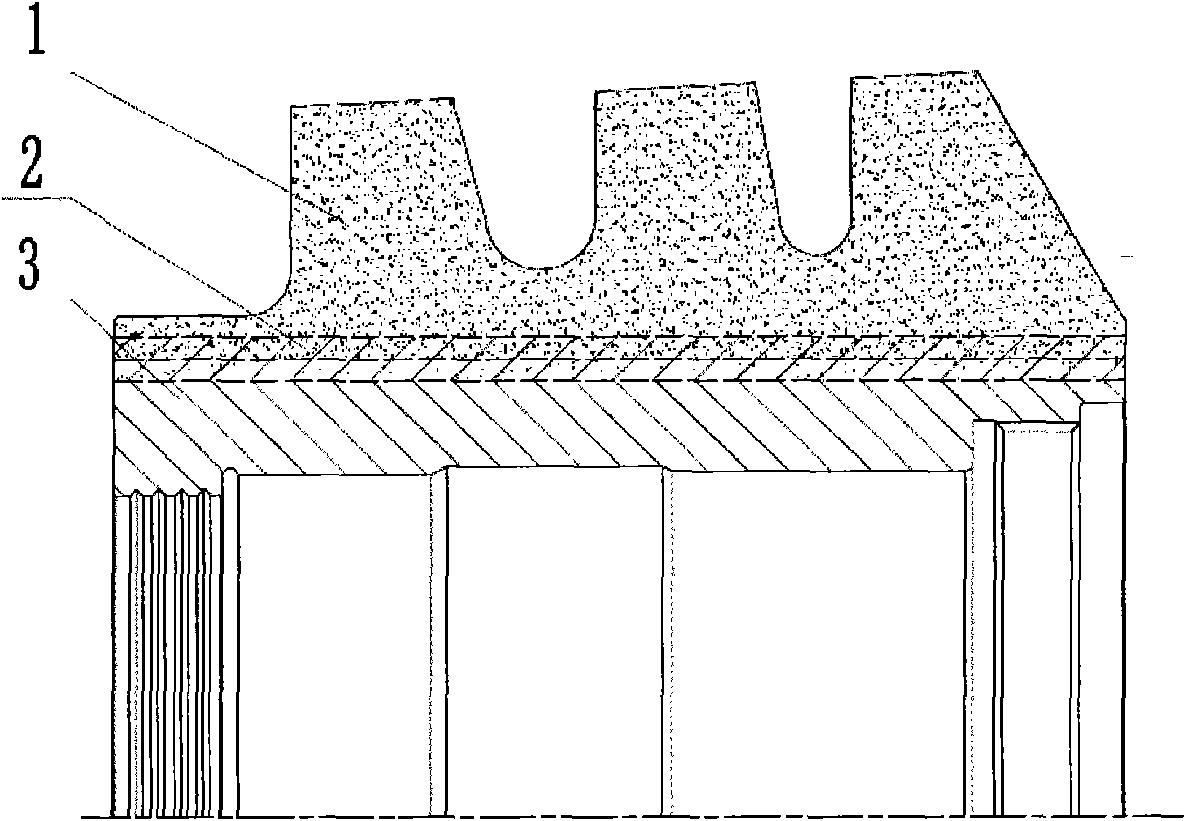

[0021] Such as figure 1 Shown is a cross-sectional view of a wedge-toothed hob shell shell cast by composite metallurgy in the present invention. The wedge-toothed hob shell includes a cutter tooth 1, a bimetallic fusion transition layer 2 and a cutter body 3, and the The double-metal fusion transition layer 2 is formed by composite smelting of wear-resistant cast steel and low-carbon alloy steel.

[0022] When casting, the above two materials of wear-resistant cast steel and low-carbon alloy steel are smelted in two 200kg intermediate frequency high-temperature furnaces in a certain proportion and order. After the molten steel reaches the appropriate temperature, a certain amount of wear-resistant cast steel molten steel is injected into a centrifuge. A certain amount of molten low-carbon alloy steel molten steel is injected into the centrifuge. During the pouring process, the centrifuge rotates continuously at variable speeds, so that the cutter teeth and cutter body parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com