Antistatic polyester film with acetylenediol surfactant and preparing method thereof

An antistatic, polyester film technology, used in polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve problems such as difficulty in finding coating compositions, easy charging on the surface of polymer films, and poor coating properties. problems, to achieve excellent transparency and anti-net performance, excellent peel strength of adhesive tape, and quickly respond to market changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Step 1: Manufacture of uniaxially stretched polyester film

[0096] The polyethylene terephthalate particles having an intrinsic viscosity of 0.625 dl / g and containing 20 ppm of amorphous spherical silica particles having an average particle diameter of 2.5 µm were sufficiently dried in a vacuum dryer at 160°C for 7 hours. Melt, extrude the dry pellets and pass them through a T-die with the help of electrostatic pins to make them in close contact with a cooling drum to produce an amorphous unstretched sheet. The unstretched sheet was heated again and stretched 3.5 times in the running direction of the film at 95° C. to produce a uniaxially stretched polyester film. Then, the surface of the film to be coated was subjected to corona discharge treatment to produce a polyester film.

[0097] Step 2: Fabrication of Biaxially Stretched Polyester Film

[0098] 100 parts by weight of conductive polymer resin (aqueous dispersion containing 0.5% by weight of poly-3,4-methyle...

Embodiment 2

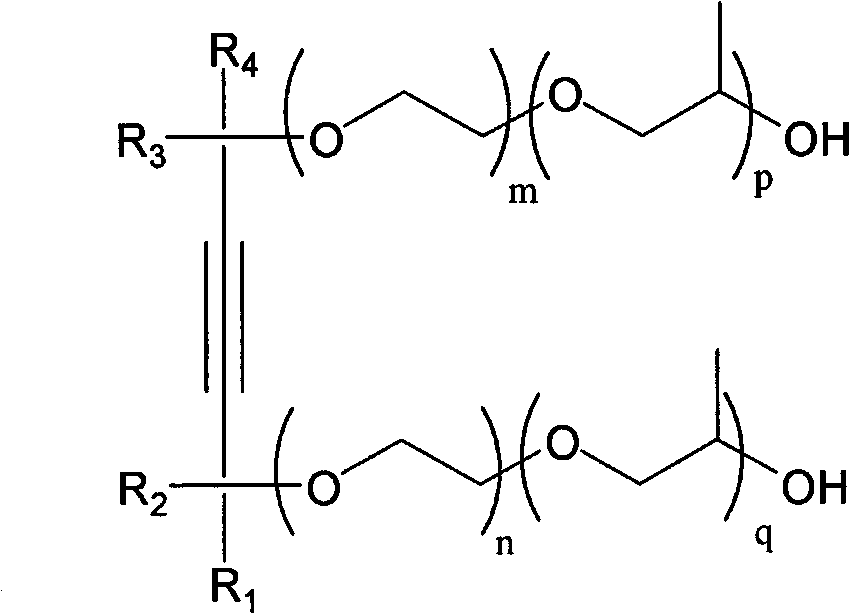

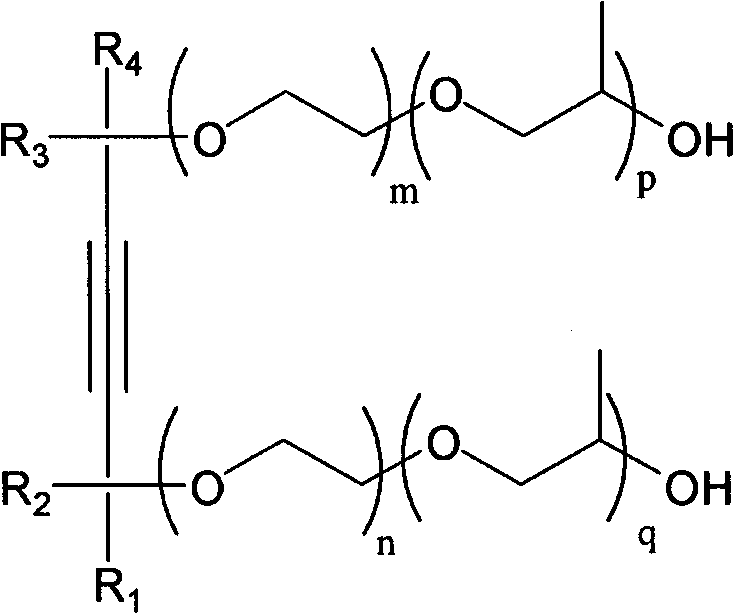

[0100] A biaxially stretched polyester film was produced in the same manner as in Example 1, except that 100 parts by weight of a conductive polymer resin (containing 0.5% by weight of poly 3,4-methylenedioxythiophene and 0.8% by weight of Aqueous dispersion of polystyrene sulfonic acid (molecular weight Mn=150,000), 400 parts by weight of polyurethane resin (anionic polyether polyurethane dispersion containing hydroxyl groups), 200 parts by weight of epoxy crosslinking agent (sold by Esprix Technologies CR-5L) and 150 parts by weight of fluororesin are mixed with each other to prepare an antistatic coating solution, and based on 100 parts by weight of the antistatic coating solution, 0.15 parts by weight of 2,5,8,11-tetramethyl Diol-6-dodecane-5,8-diol ethoxylate was added to the antistatic coating solution, and the solid content of the antistatic coating solution was 2.0% by weight.

Embodiment 3

[0102] A biaxially stretched polyester film was produced in the same manner as in Example 1, except that an anionic polyether polyurethane dispersion containing allylamine and its repeating unit as a functional group of the polyurethane resin was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com