Method for preparing high-active piezoelectric functional membranes by microwave irradiation

A technology of microwave irradiation and high activity, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of difficult process control, high cost, Troublesome problems such as microporous membranes, to achieve the effect of low production cost, easy investment in equipment, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

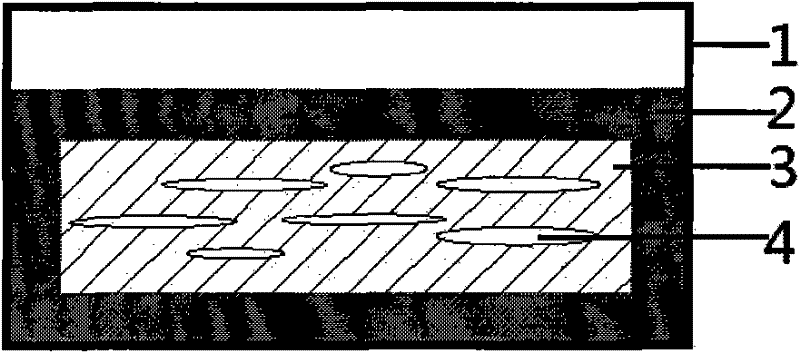

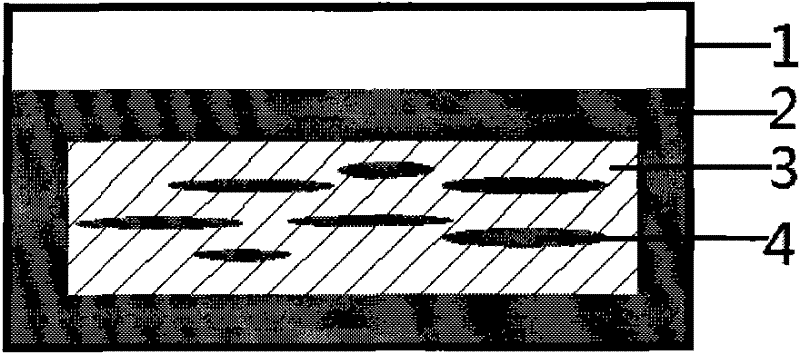

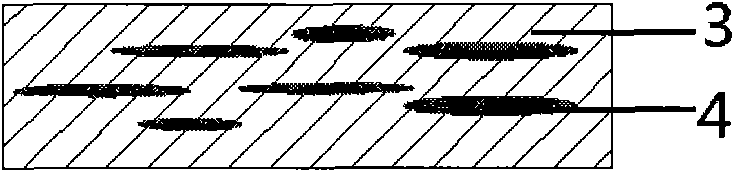

[0025] Cut a commercially available polypropylene porous membrane (pp) of model PQ50 into a 3cm×3cm sample as the original membrane soaked in a commercially available reagent grade methylene chloride (CH 2 Cl 2 ) Seal and soak in the solvent container 1 for 20 hours. The original film is composed of the film 3 and the hole 4. After the hole 4 is completely immersed in the solvent, the original film is taken out of the solvent 2 and placed in a petri dish, and placed in the irradiation energy 1.99×10 -25 ~1.99×10 -22 Irradiate under the microwave of J for 50-100s. The temperature of the solvent rises by microwave heating. The solvent in hole 4 is heated to evaporate into gas to achieve the effect of puffing the holes. The irradiated original film is immediately cooled in 0℃ ice water. A piezoelectric functional film with high piezoelectric activity is obtained.

[0026] The volume of the hole 4 of the original film just immersed in the solvent (see figure 1 ) And the volume of hole...

Embodiment 2

[0032] In addition to changing the reagents to reagent grade chloroform (CHCl 3 ) Solvent, except that the immersion time after sealing is 21h, the other processes are the same as in Example 1, that is, a piezoelectric functional film with high piezoelectric activity is obtained.

[0033] By using the same measurement method as in Example 1, the volume change trend of the hole 4 detected by the cross-sectional scanning electron microscope is the same as in Example 1.

[0034] Comparing the thickness of the piezoelectric functional film sample with high piezoelectric activity obtained in the present invention and the original film (unit: μm), it is found that the thickness of the original film is 50 μm, and the thickness of the sample of Example 2 is 66.25 μm (please see Picture 11 ), the thickness of the present invention is 32.5% higher than that of the original film.

[0035] Compare the density of the piezoelectric functional film sample with high piezoelectric activity obtained i...

Embodiment 3

[0038] In addition to replacing the reagents with commercially available reagent grade acetone (CH 3 COCH 3 ) Solvent, other processes are the same as in Example 1, except that the soaking time after sealing is 23h. That is, a piezoelectric functional film with high piezoelectric activity is obtained.

[0039] By using the same measurement method as in Example 1, the volume change trend of the hole 4 detected by the cross-sectional scanning electron microscope is the same as in Example 1.

[0040] Comparing the thickness of the obtained piezoelectric functional film sample with the original film (unit: μm): the thickness of the original film is 50 μm, and the thickness of the sample of Example 3 is 65 μm (see Picture 11 ), the thickness of the present invention is 30% greater than the thickness of the original film.

[0041] Compare the density of the piezoelectric functional film sample with high piezoelectric activity and the original film (unit: g / cm 3 ) It is found that the dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com