Low-temperature transfer printing method used for microelectronically packaged carbon nanotube bumps

A technology of microelectronic packaging and carbon nanotubes, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as the inability to meet the development requirements of high density and miniaturization of electronic components, large bump size and spacing, etc. , to achieve the effect of reducing package size, high success rate transfer, and satisfying high-density packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the specific process and steps of the low-temperature transfer printing method of carbon nanotube bumps are as follows:

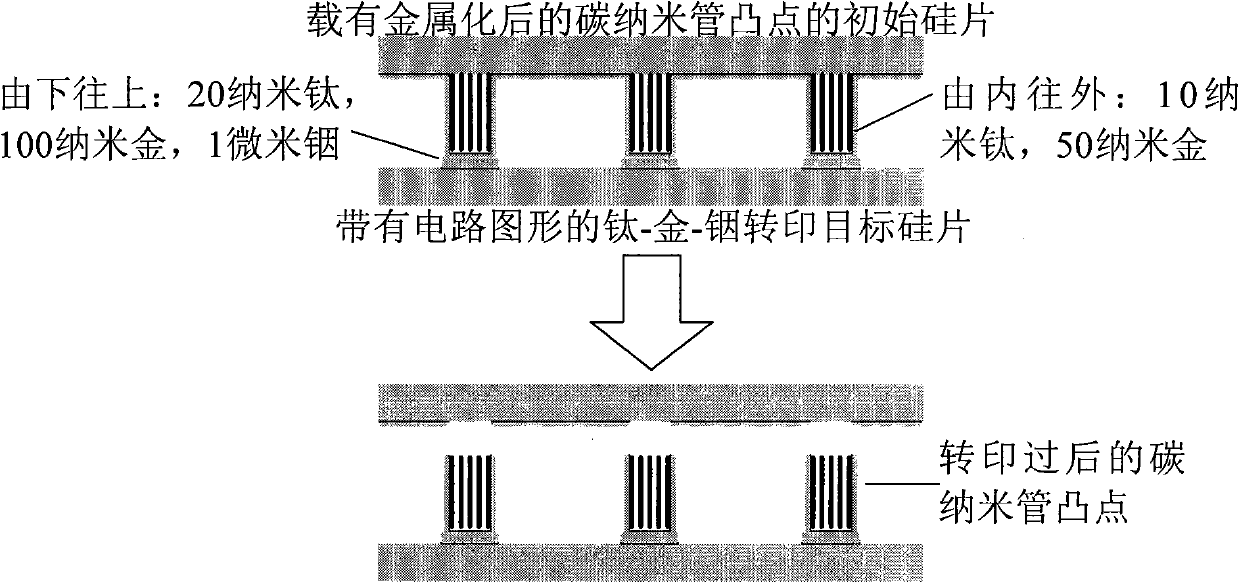

[0024] see figure 1 , figure 1 It is a schematic diagram of the transfer printing process for forming carbon nanotube bumps from carbon nanotube arrays in the present invention.

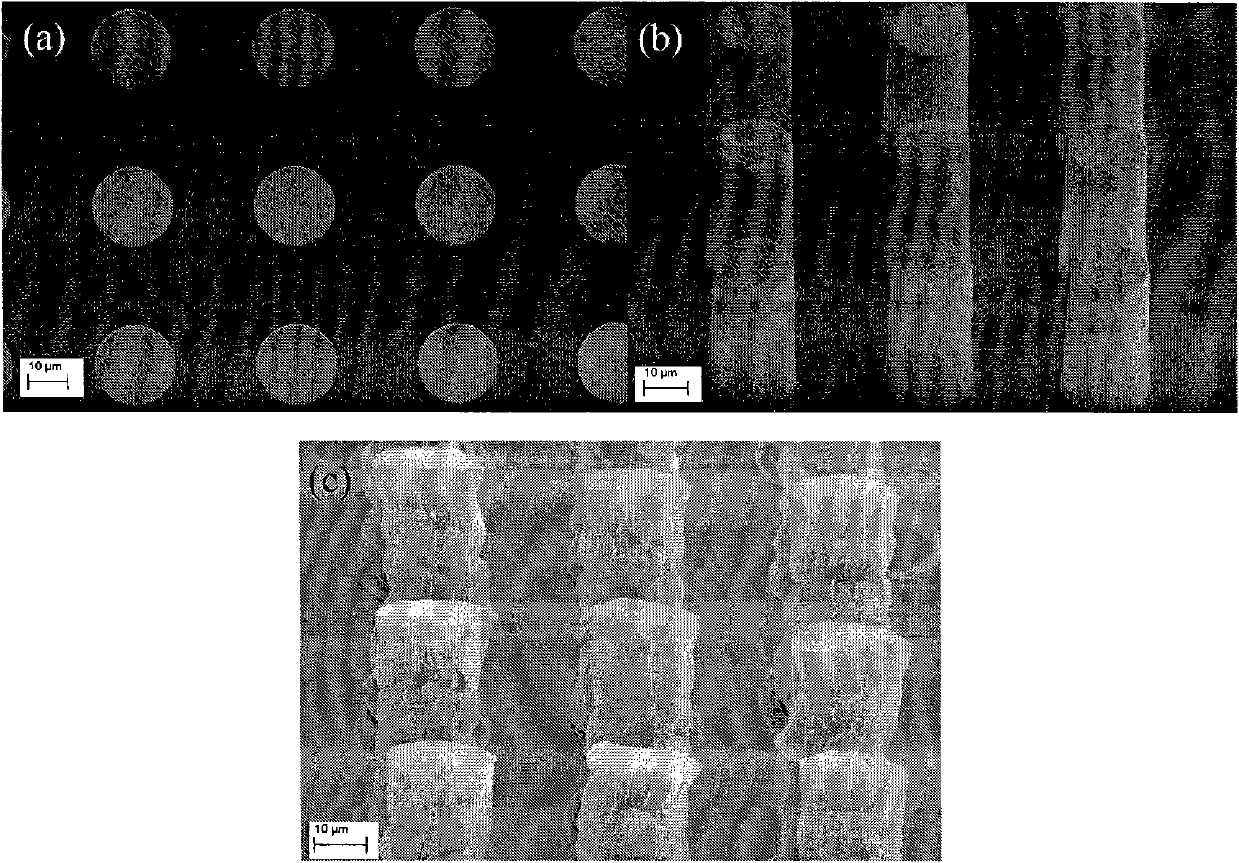

[0025] (1) First, a pattern array of 100×100 is engraved on the transfer target silicon wafer by ultraviolet lithography, each pattern is a circle with a diameter of 20 microns, and the distance between the circles is 40 microns.

[0026] (2) Using a sputtering method to sequentially deposit a titanium metal layer and a gold metal layer on the transfer target silicon wafer and the photoresist to form a conductive layer, wherein the thickness of titanium is 20 nanometers, and the thickness of gold is 100 nanometers.

[0027] (3) Deposit a transfer layer made of metal indium on the gold metal layer of the transfer target silicon wafer by electron beam ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com