Double long branch-chain polycarboxylic acid water reducing agent and preparation process thereof

A technology of branched polycarboxylate and water reducer, which is applied in the field of double long chain branched polycarboxylate water reducer, can solve the problems of poor cement adaptability, complex production process, and low water reducing rate, and achieve slump The effect of small loss of strength, low dosage, and improvement of early and late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

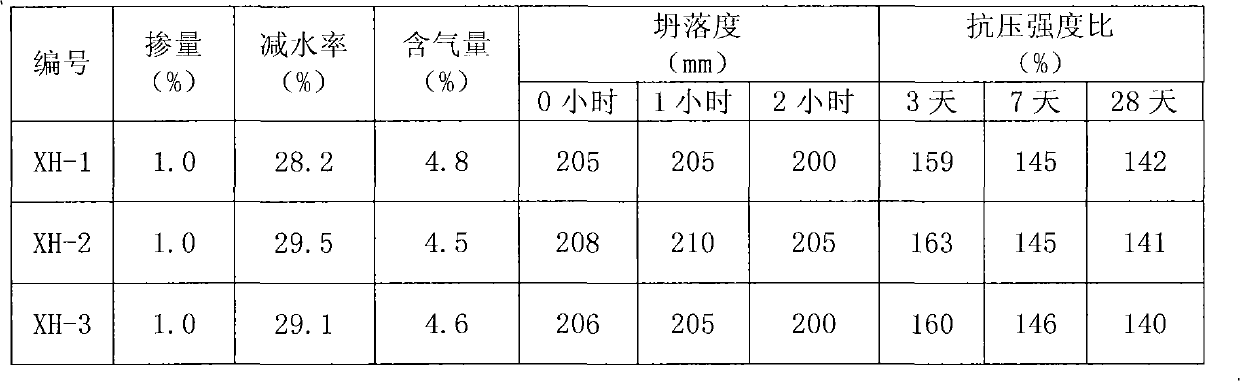

Embodiment 1

[0023] Add 50g of water into a 250ml four-necked flask equipped with a thermometer, a stirrer, a dropping funnel, and a condenser, and heat it to 80°C; Mixed aqueous solution of 15g monomethacrylate, 1.6g sodium 2-acrylamide-2 methylpropyl sulfonate, 13.2g methacrylic acid and 107g water, and 1.1g ammonium persulfate and 90g water solution, dropwise addition time Control at 5±0.5 hours; after the addition is completed, keep the constant temperature at 80-90°C and continue the reaction for 4 hours. After the reaction is completed, add 6.3g of 40wt% sodium hydroxide aqueous solution dropwise to neutralize to about PH=7 to obtain a polycarboxylate water reducer Product XH-1. The measurement performance indicators are shown in Table 1.

Embodiment 2

[0025] Add 50g of water into a 250ml four-neck flask equipped with a thermometer, stirrer, dropping funnel, and condenser, and heat to 80±5°C; at the same time, dropwise add 30g of methoxypolyethylene glycol methacrylate, polyethylene glycol Diol monomethacrylate 10g, 2.2g of sodium 2-acrylamide-2 methylpropyl sulfonate, methacrylic acid 12.8g and water 107g mixed aqueous solution, and ammonium persulfate 2.6g and water 90g aqueous solution, drop Adding time is controlled at 5 ± 0.5 hours; after the dropwise addition is completed, the constant temperature is continued at 80-90°C for 4 hours, and after the reaction is completed, 6.1g of 40wt% sodium hydroxide aqueous solution is added dropwise to neutralize to about PH=7, and polycarboxylic acid is obtained. Aqueous product XH-2. The measurement performance indicators are shown in Table 1.

Embodiment 3

[0027] Add 50g of water into a 250ml four-neck flask equipped with a thermometer, agitator, dropping funnel, and condenser, and heat it to 80±5°C; at the same time, add 35g of methoxypolyethylene glycol methacrylate, polyethylene glycol A mixed aqueous solution of 5 g of glycol monomethacrylate, 0.85 g of sodium 2-acrylamide-2 methylpropyl sulfonate, 15.3 g of methacrylic acid and 107 g of water, and an aqueous solution of 4.1 g of ammonium persulfate and 90 g of water, drop Adding time is controlled at 5 ± 0.5 hours; after the dropwise addition is completed, the constant temperature is kept at 80-90° C. to continue the reaction for 4 hours, and after the reaction is completed, 7.0 g of 40 wt % sodium hydroxide aqueous solution is added dropwise to neutralize to about PH=7, and polycarboxylic acid is obtained. Aqueous product XH-3. The measurement performance indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com