Method for preparing polyvinyl alcohol magnetic film

A polyvinyl alcohol, magnetic film technology, applied in spinning solution preparation, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problem of poor bonding between film and substrate, poor process repeatability, and deposition rate. Low problems, to achieve the effects of excellent magnetic properties, shortened production time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

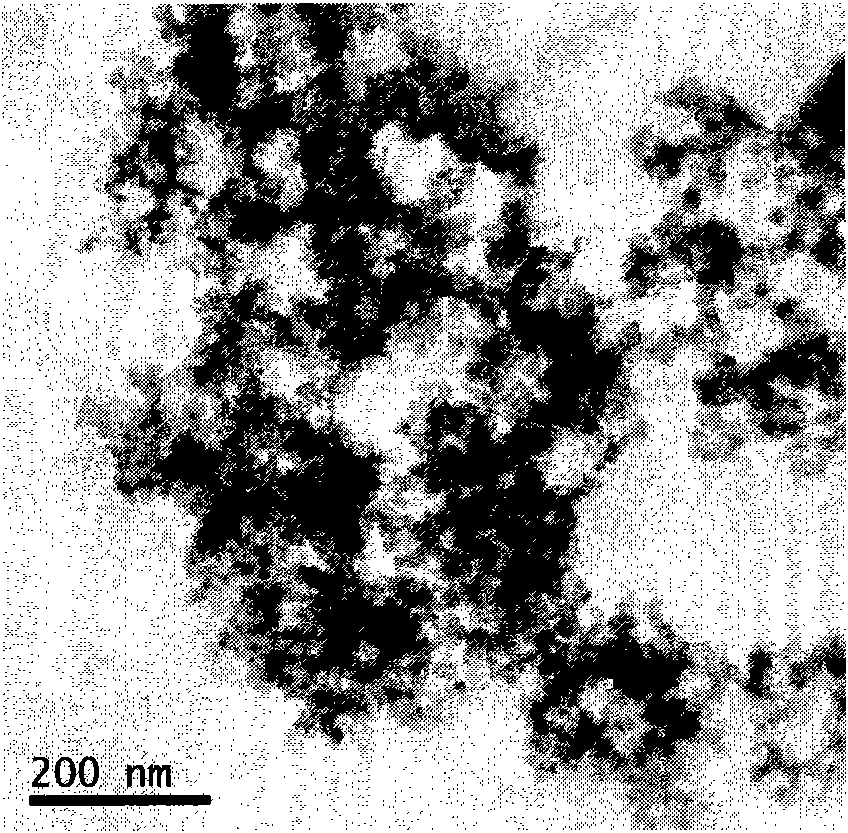

[0021] 1. Fe with good dispersibility 3 o 4 Preparation of aqueous solution system

[0022] Sodium dodecylbenzenesulfonate (C 18 h 29 NaO 3 S), citric acid (C 6 h 8 o 7 ·H 2 O) and egg protein powder (LDB) as a dispersant for Fe 3 o 4 Disperse processing.

[0023] Add equal amounts of the above-mentioned dispersants into conical flasks containing equal amounts of deionized water respectively, and stir at the same speed for 0.5 hours. According to the mass ratio, the dispersant: Fe 3 o 4 = 1:1 add the same amount of nano-Fe respectively 3 o 4 Particles were dispersed by ultrasonic oscillation at a frequency of 45kHz for 10 minutes. Leave it for a day to observe its dispersion effect: C 18 h 29 NaO 3 S and C 6 h 8 o 7 ·H 2 Nano-Fe in Erlenmeyer flask with O as dispersant 3 o 4 The particles are all precipitated, and the solution is colorless; the nano-Fe in the Erlenmeyer flask with LDB as the dispersant 3 o 4 Particles were only partially precipitated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com