ZnO/ZnMgO multi-quantum trap ultraviolet laser diode and preparation method thereof

A multi-quantum well and ultraviolet laser technology is applied in the field of laser diodes and their preparation to achieve the effects of improving crystal quality, good lattice matching, and realizing industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Substrate cleaning: Use n-type GaN grown on sapphire as the substrate, cut it into a size of 15mm×15mm, ultrasonically clean it with acetone, alcohol, and deionized water for 3 minutes, and finally dry it with a nitrogen gun.

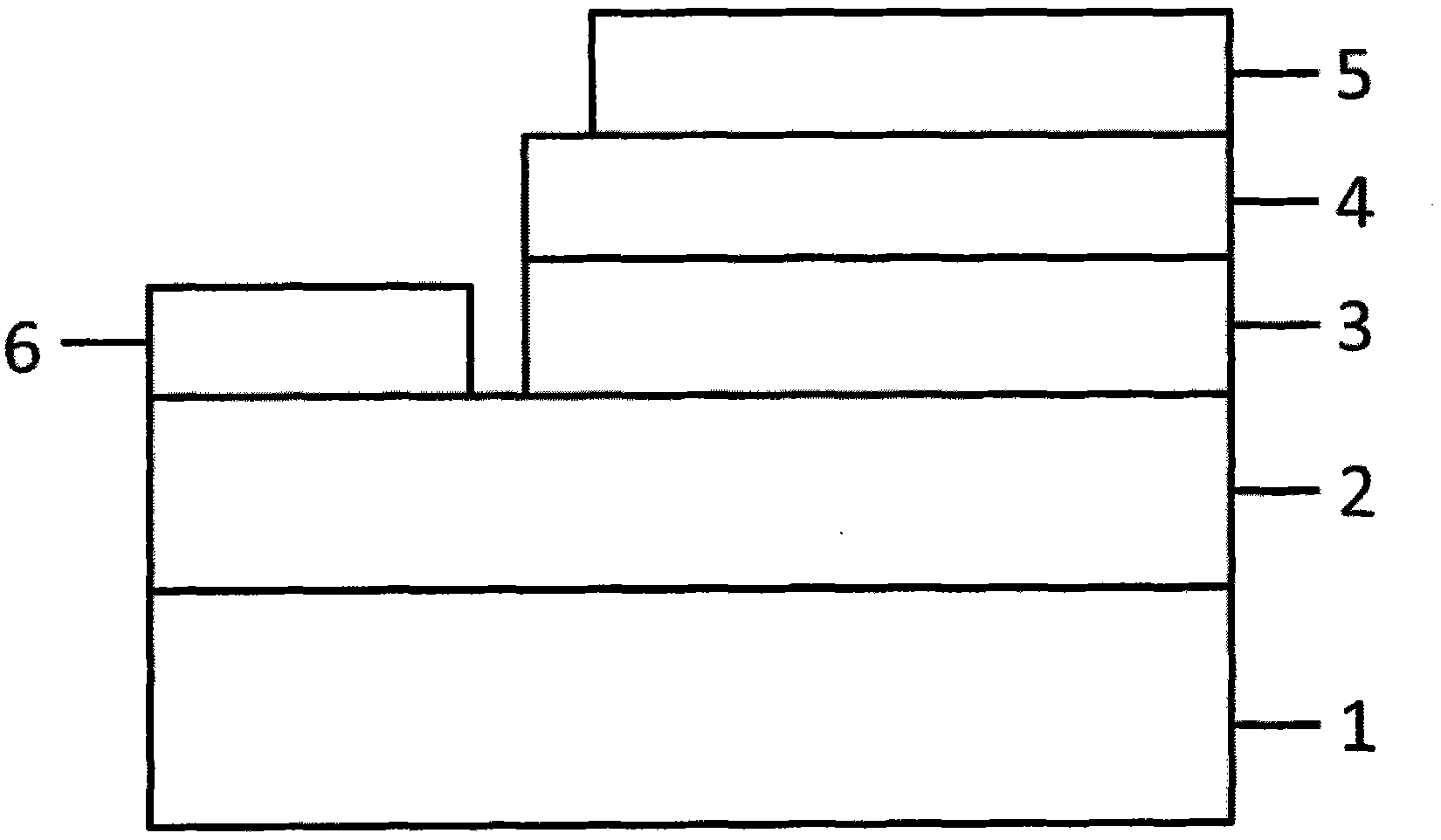

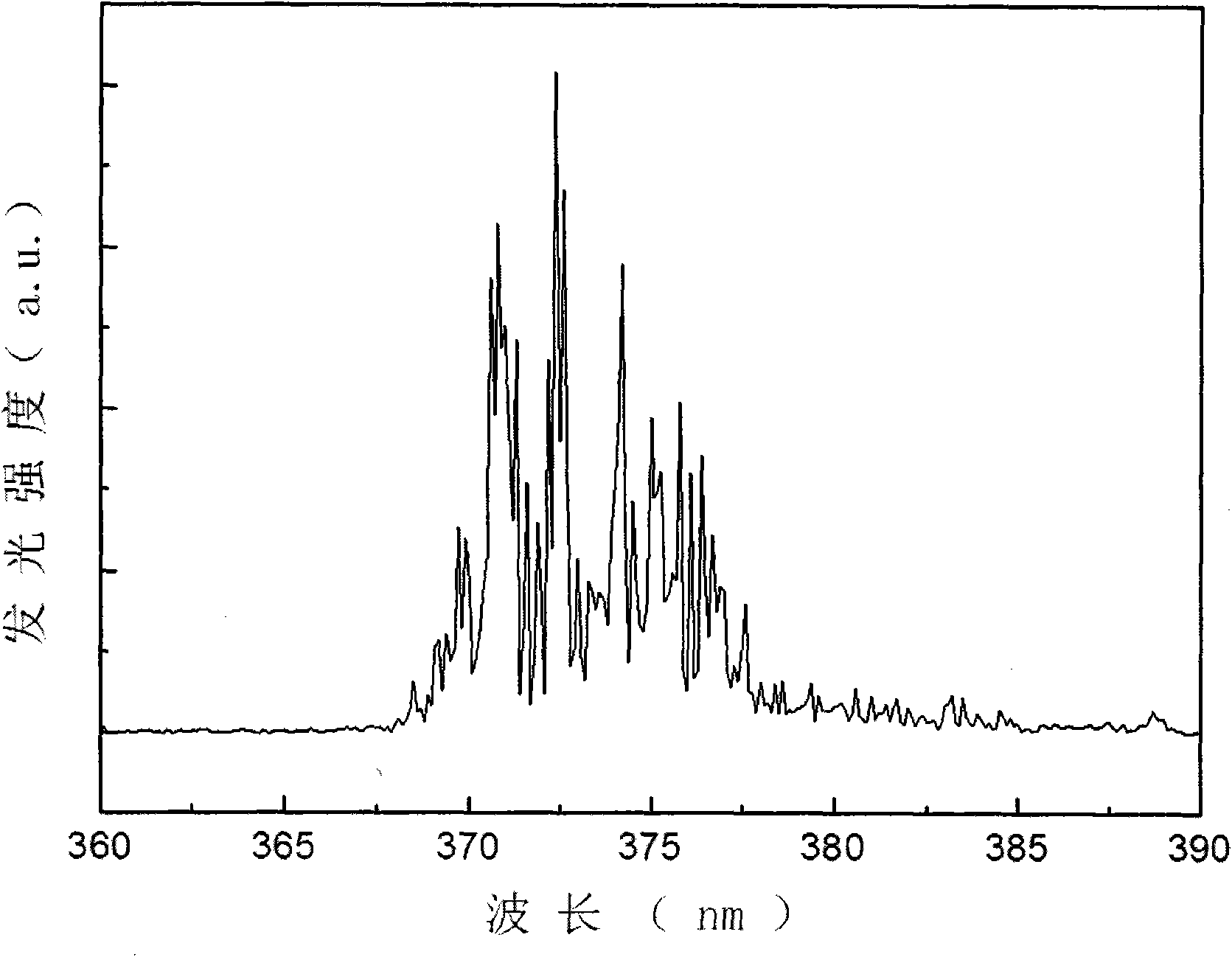

[0027] 2. ZnO / Zn 1-x Mg x O Growth of multi-quantum well active layer: put the substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and the growth chamber is evacuated to the background pressure of 5×10 -4 Pa, heating the substrate to a temperature of 250°C. ZnO ceramic target is selected as the target material for depositing ZnO potential well layer, and a mixed target material of Mg metal target and ZnO ceramic target is selected as the target material for depositing ZnO potential well layer. 1-x Mg x The target material of the O barrier layer, wherein the area ratio of the Mg metal target and the ZnO ceramic target is 2:3, the Zn 1-x Mg x x=0.1 in the O layer. Before coating, pre...

Embodiment 2

[0032] 1. Substrate cleaning: Use n-type GaN grown on sapphire as the substrate, cut it into a size of 15mm×15mm, ultrasonically clean it with acetone, alcohol, and deionized water for 3 minutes, and finally dry it with a nitrogen gun.

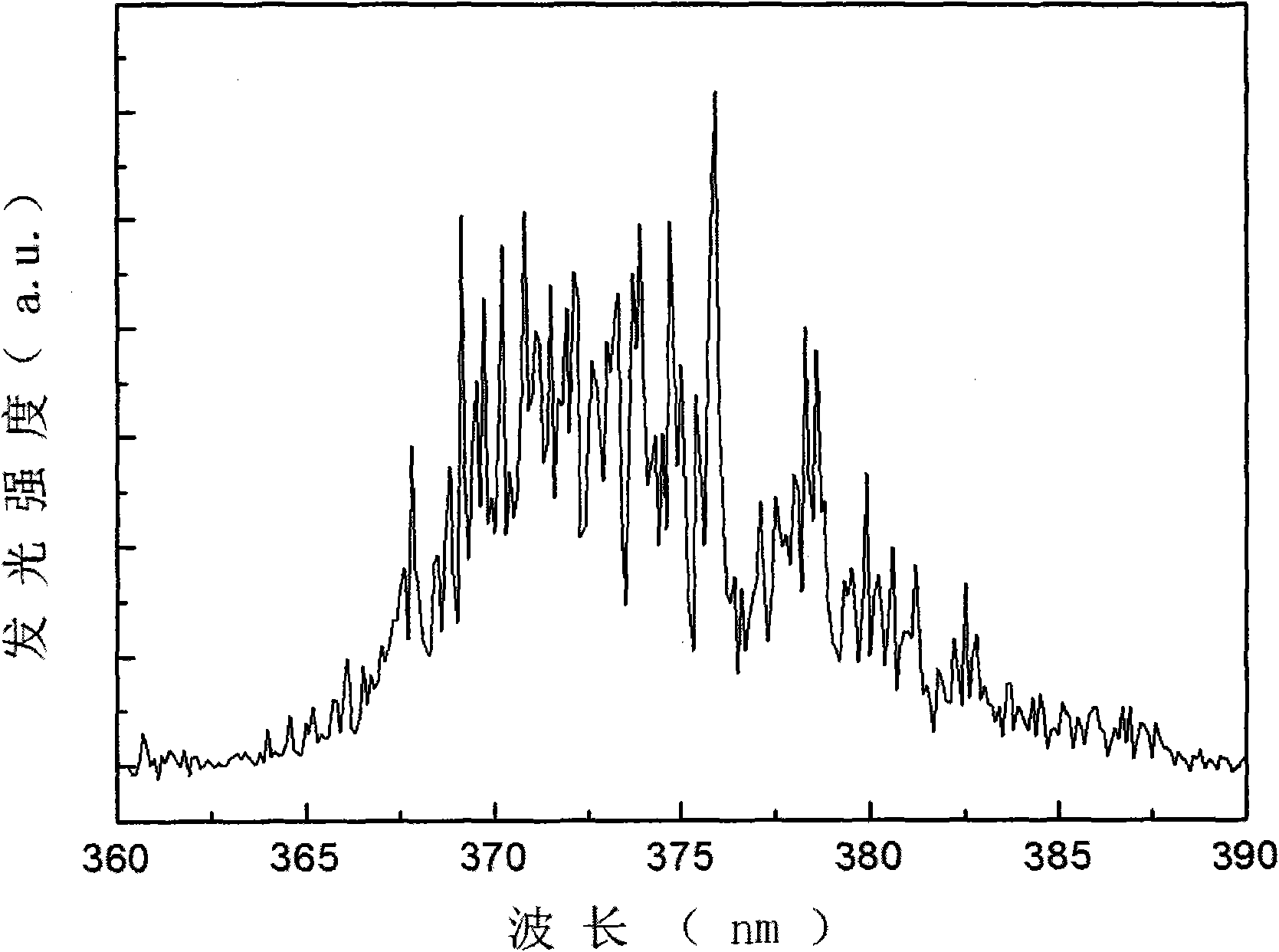

[0033] 2. ZnO / Zn 1-x Mg x O Growth of multi-quantum well active layer: put the substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and the growth chamber is evacuated to the background pressure of 1×10 -3 Pa, heating the substrate to a temperature of 200°C. ZnO ceramic target is selected as the target material for depositing ZnO potential well layer, and a mixed target material of Mg metal target and ZnO ceramic target is selected as the target material for depositing ZnO potential well layer. 1-x Mg x The target material of the O barrier layer, wherein the area ratio of the Mg metal target and the ZnO ceramic target is 1:1, the Zn 1-x Mg x x=0.18 in the O layer. Before coating, pr...

Embodiment 3

[0037] 1. Substrate cleaning: Use n-type GaN grown on sapphire as the substrate, cut it into a size of 15mm×15mm, ultrasonically clean it with acetone, alcohol, and deionized water for 3 minutes, and finally dry it with a nitrogen gun.

[0038] 2. ZnO / Zn 1-x Mg x O Growth of multi-quantum well active layer: put the substrate after surface cleaning into the growth chamber of the radio frequency magnetron sputtering system, and the growth chamber is evacuated to the background pressure of 1×10 -3 Pa, heating the substrate to a temperature of 300°C. ZnO ceramic target is selected as the target material for depositing ZnO potential well layer, and a mixed target material of Mg metal target and ZnO ceramic target is selected as the target material for depositing ZnO potential well layer. 1-x Mg x The target material of the O barrier layer, wherein the area ratio of the Mg metal target and the ZnO ceramic target is 1:1, the Zn 1-x Mg x x=0.18 in the O layer. Before coating, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com