Silicate antirust liquid

A technology of anti-rust liquid and silicate, which is applied in the coating process of metal materials, etc., can solve problems such as harmful to health, release of aromatic hydrocarbons, accumulation of heavy metals, etc., and achieve low production cost, low cost of anti-rust, and excellent product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

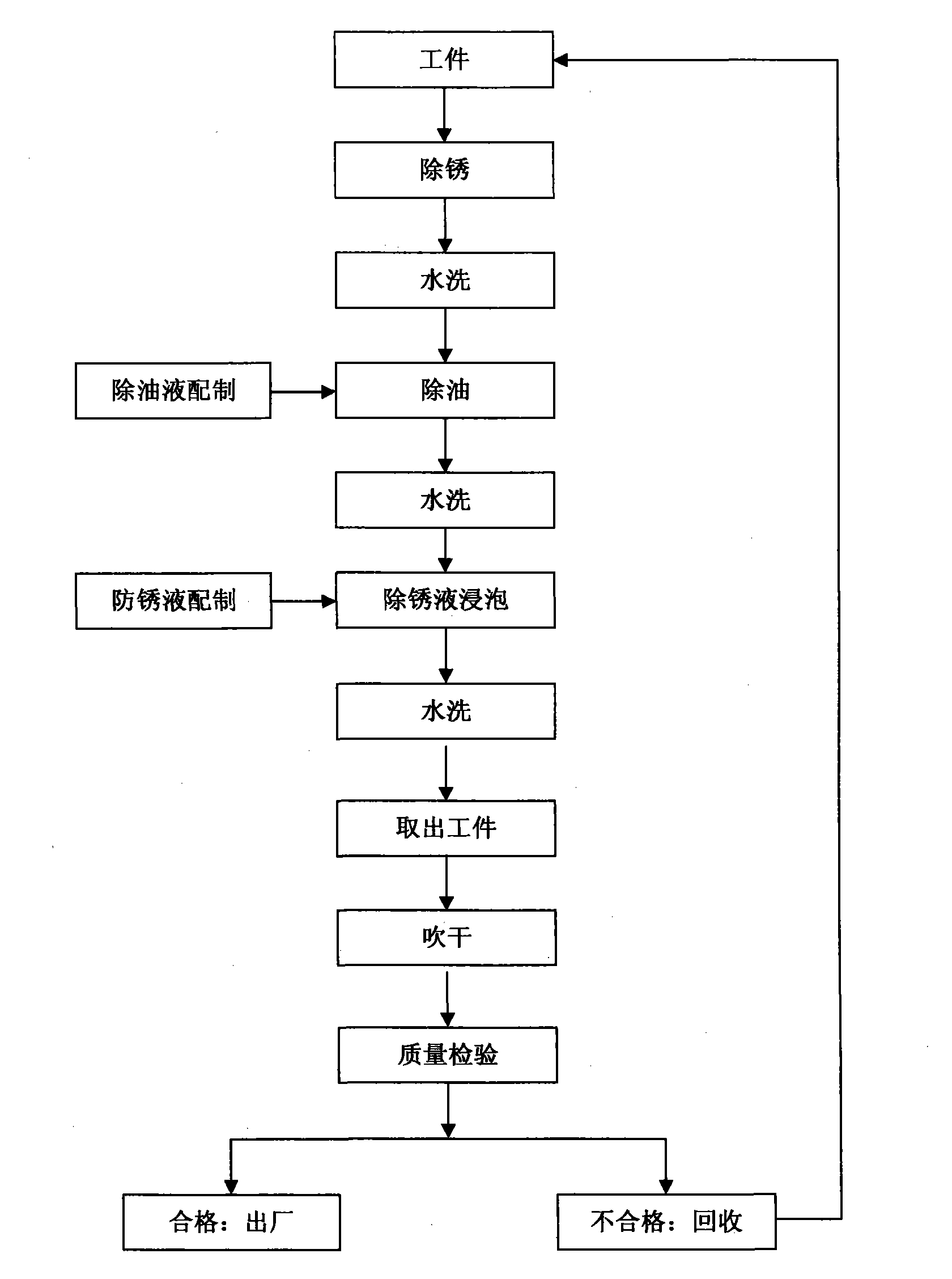

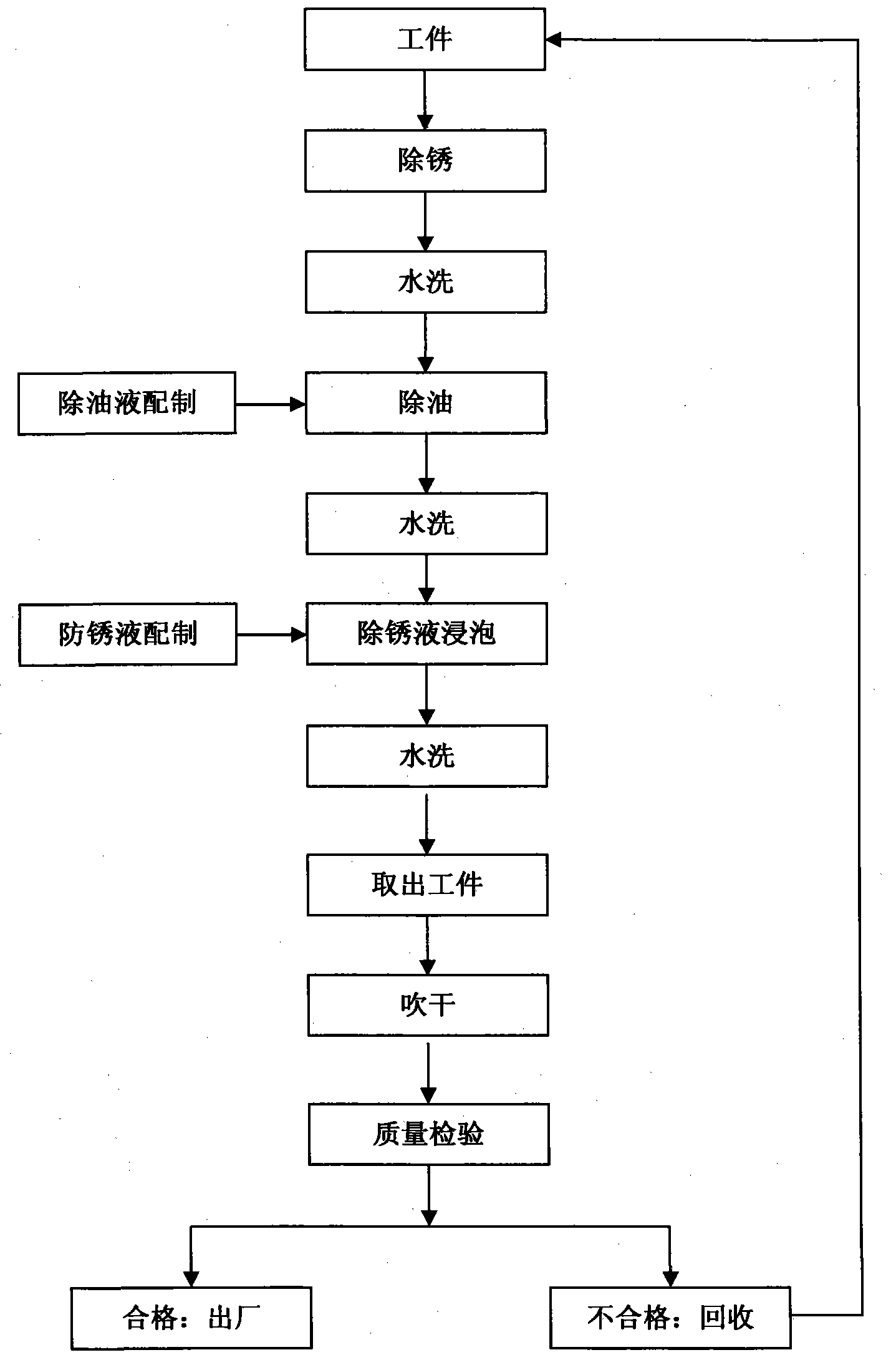

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the composition of this iron and steel parts antirust liquid is sodium silicate 10g / L, H 2 o 2 10ml / L, NaNO 3 10g / L, Zn(NO 3 ) 2 25g / L, H 2 SO 4 4ml / L, the rest is H 2 O, the pH value is 3.0.

[0016] The antirust solution is used for silicate antirust treatment on steel plates that need antirust treatment. After the steel plate is subjected to pre-treatments such as derusting and degreasing before electroplating, the parts are taken out and cleaned, and then put into the steel plate by HNO 3 2ml / L and H 2 Stay in the light-emitting solution composed of O for 5 seconds, take out the parts and clean them with water, then soak them in this anti-rust solution at room temperature for 25 seconds, and finally clean the parts and dry the surface moisture of the parts with a hair dryer.

[0017] The appearance of the steel plate treated with this anti-rust solution is uniform and has a metallic luster, and the red rust time exceeds 80 hours through the ne...

Embodiment 2

[0018] Embodiment 2: the composition of this antirust liquid is potassium silicate 15g / L, H 2 o 2 10ml / L, NaNO 3 15g / L, Zn(NO 3 ) 2 30g / L, H 2 SO 4 3ml / L, the rest is H 2 O, the pH value is 2.0.

[0019] The antirust solution is used for antirust treatment of certain engine blades. After the blades are pre-treated (rust removal, oil removal), they are taken out and cleaned with water, and then put into the 3 3ml / L and H 2 Stay in the light-emitting solution composed of O for 6 seconds, take out the parts and clean them with water, then soak them in this anti-rust solution at room temperature for 15 seconds, and finally clean the parts and dry the surface moisture of the parts with a hair dryer.

[0020] The engine blades treated with this anti-rust solution have uniform appearance and metallic luster, and the red rust time exceeds 70 hours in the neutral salt spray test, which greatly exceeds the corrosion resistance of the existing treatment process.

Embodiment 3

[0021] Embodiment 3: the composition of this antirust liquid is sodium silicate 20g / L, H 2 o 2 15ml / L, NaNO 3 10g / L, Zn(NO 3 ) 2 40g / L, H 2 SO 4 8ml / L, the rest is H 2 O, the pH value is 1.5.

[0022] The anti-rust liquid is used for anti-rust treatment of the steel casing of a certain machine. The steel casing is cleaned with water after pre-treatment (rust removal, oil removal), and then put into the HNO 3 5ml / L and H 2 Stay in the light-emitting solution composed of O for 3 seconds, take out the parts and clean them with water, then soak them in this anti-rust solution at room temperature for 15 seconds, and finally clean the steel casing and dry the surface moisture of the parts with a hair dryer.

[0023] The steel casing treated with this anti-rust solution has a uniform appearance and a metallic luster, and the red rust time exceeds 50 hours after the neutral salt spray test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com