Method for largely preparing superfine spherical titanium aluminium-based alloyed powder

A technology of base alloy and alloy powder, which is applied in the field of preparation of fine spherical titanium-aluminum base alloy powder, which can solve the problems of TiAl base alloy powder that have not been seen yet, and achieve the effect of fine particle size, high operation stability and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

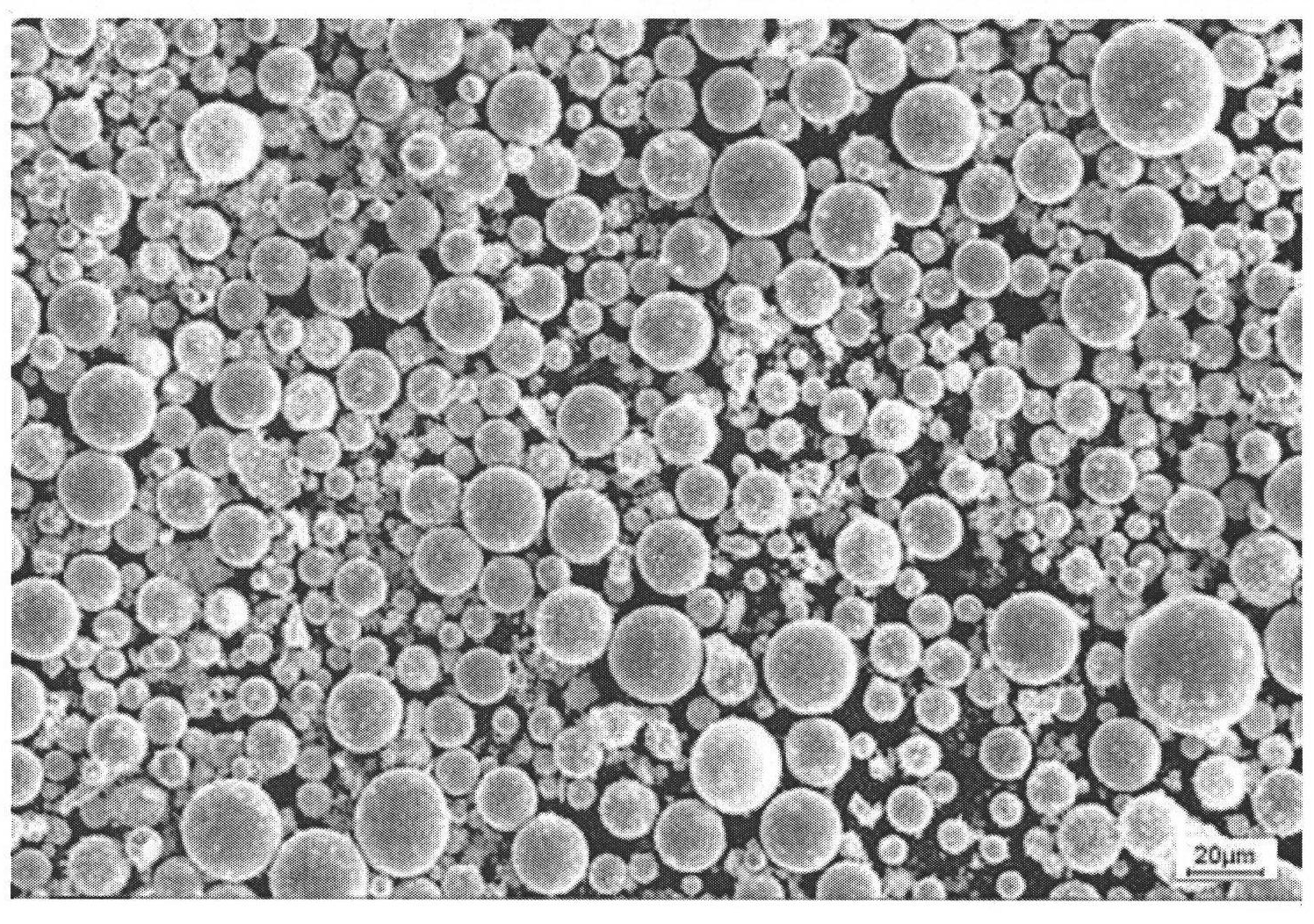

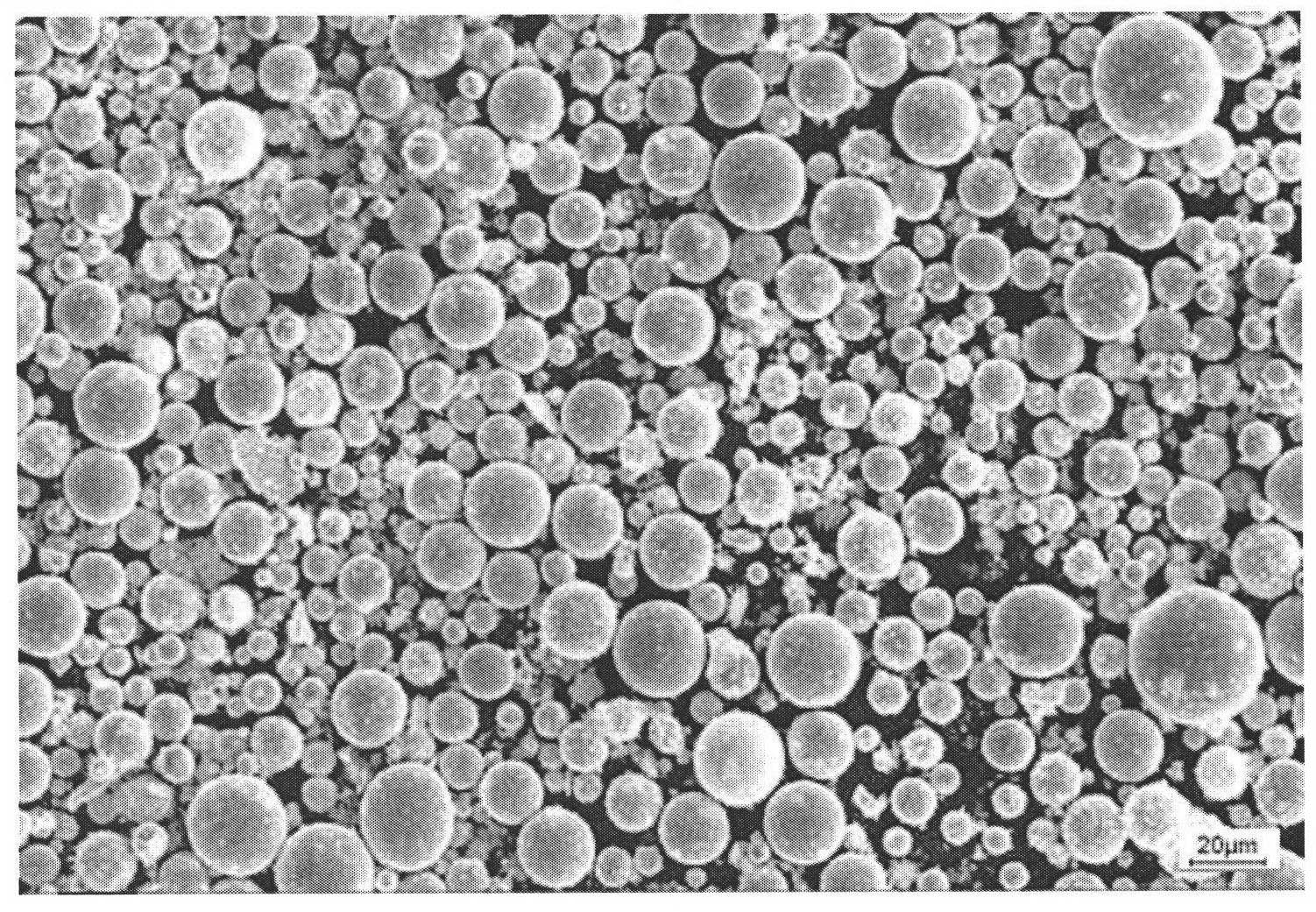

[0015] Example 1. Using high-purity aluminum with a purity of 99.99%, titanium sponge, Al-Nb master alloy, Ti-B alloy, tungsten powder, and yttrium scrap with a purity of 99.99% as raw materials, it is smelted by a plasma cooling bed furnace melting process Large size ingots with a nominal composition of Ti-45Al-9 (Nb, W, B, Y). The alloy ingot is coarsely crushed by low-temperature cold air chips, the temperature of the compressed nitrogen cold air is -30°C, and the particle size of the chips is about 2mm. The debris was subjected to vortex jet mill grinding, the grinding nitrogen pressure was 0.65Mpa, the rotating speed of the separator was 5800 rpm, and irregular fine alloy powder with an average particle size of 18 μm was collected. The fine alloy powder is subjected to radio frequency plasma spheroidization treatment, the plasma stable power is 35KW, the flow rate of argon working gas is 23 slpm, the flow rate of argon protective gas is 155 slpm, and the system negative p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com