Over-current and over-temperature protection element with positive temperature coefficient and preparation method thereof

A positive temperature coefficient and temperature protection technology, which is applied in the direction of resistors with positive temperature coefficients, current response resistors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of high filling capacity of conductive fillers and machine blockage , the viscosity increase of composite materials and other problems, to achieve the effect of high PTC strength, good bonding force, and low room temperature resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

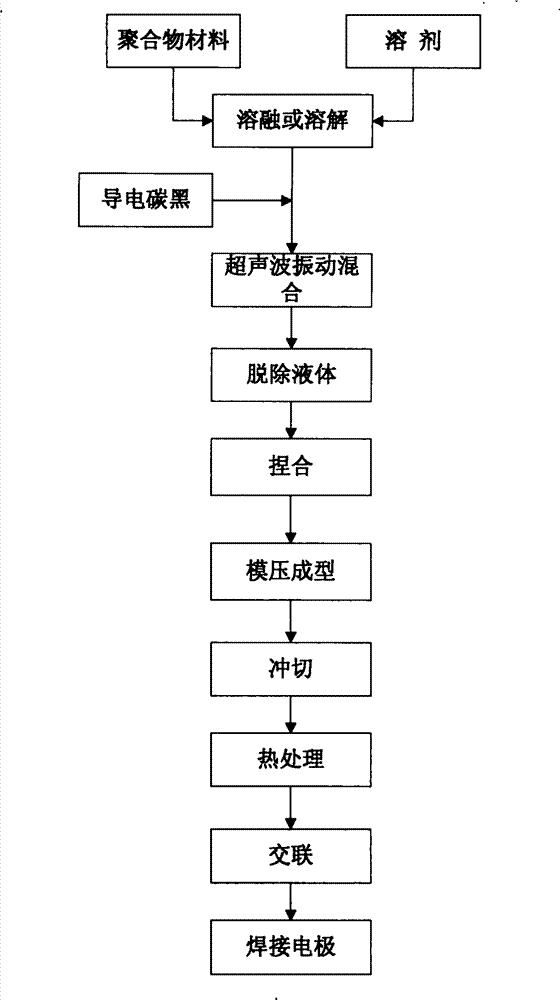

Method used

Image

Examples

Embodiment 1

[0041] PVDF, ECTFE, and CB are proportioned according to the weight percentage of 46:6:48. First, polyvinylidene fluoride and ECTFE (a copolymer of ethylene and chlorotrifluoroethylene) are added to dimethylacetamide and heated at 20°C to 60°C. Stir and dissolve at ℃, add conductive carbon black after completely dissolved, then stir and mix the above solution by ultrasonic vibration, mix at 20℃~60℃, mixing time 15~60min, so that conductive carbon black is evenly distributed in the In the solution, a suspension with a high concentration of carbon black is formed to reach a gel state mixture, and a carbon black dispersant can be added during the mixing process to enhance the dispersion effect of carbon black. The above-mentioned mixture in gel state is extracted to remove dimethylacetamide to obtain a mixture composed of polymer and conductive carbon black. Kneading the obtained mixture of the polymer and the conductive carbon black in a heated state by means of an open mill to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com