Selective heap leaching gold extraction process for gold mine containing copper

A selective and heap leaching technology, which is applied in the field of hydrometallurgy, can solve the problems of high cost, large consumption of sodium cyanide, and environmental pollution, and achieve the effects of low consumption, high gold leaching rate, and wide utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

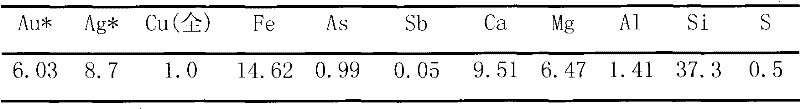

[0024] It comes from a copper-bearing gold mine in Yunnan, enriched by conventional cyanide heap leaching, the gold recovery rate is only about 60%, and the sodium cyanide consumption is greater than 10kg / t mine. The copper in the copper-bearing gold ore exists in the form of oxide ore, and the chemical composition of the ore is shown in Table 1.

[0025] Table 1 Chemical composition of a copper-bearing gold deposit in Yunnan

[0026]

[0027] *The unit is g / t.

[0028] The particle size of the raw ore is -60mm, the pH value is adjusted to 9.5 with lime, and 200g / L ammonium carbonate and 5g / L sodium cyanide are added for selective heap leaching. The heap height is 6m, and the heap leaching period is 6 months. 10L / (h·m 2 ), the leaching rate of gold is 77.4%, and the consumption of sodium cyanide is 1.7kg / t ore.

Embodiment 2

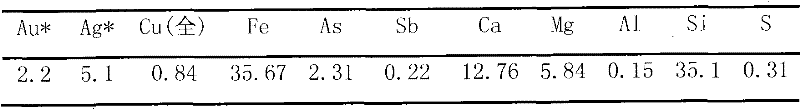

[0030] It comes from a copper-bearing gold mine in Fujian, enriched by conventional cyanide heap leaching, the gold recovery rate is only 65%, and the sodium cyanide consumption reaches 18kg / t mine. The copper in this copper-bearing gold ore exists in the mixed form of oxide ore and sulfide ore, and the chemical composition of the ore is shown in Table 2.

[0031] Table 2 Chemical composition of a copper-bearing gold deposit in Fujian

[0032]

[0033] *The unit is g / t.

[0034] The particle size of the raw ore is -20mm, adjust the pH value to 12 with caustic soda, add 5g / L ammonium carbonate, 50g / L ammonium chloride, 5g / L sodium cyanide for selective heap leaching, the heap height is 3m, and the heap leaching The cycle is 2 months, the spray intensity is 30L / (h·m 2 ), the leaching rate of gold is 86.4%, and the consumption of sodium cyanide is 1.1kg / t ore

Embodiment 3

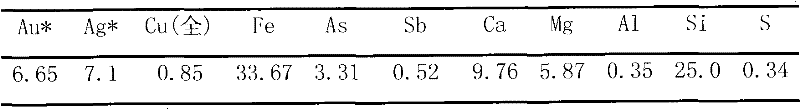

[0036] It comes from a copper-bearing gold mine in Tajikistan, enriched by conventional cyanide heap leaching, the gold recovery rate is only 45%, and the sodium cyanide consumption reaches 20kg / t mine. The copper in the copper-bearing gold ore exists in the form of oxide ore, and the chemical composition of the ore is shown in Table 3.

[0037] Table 3 Chemical composition of a copper-bearing gold deposit in Tajikistan

[0038]

[0039] *The unit is g / t.

[0040] The particle size of the raw ore is -30mm, the pH value is adjusted to 12 with lime, and 0.5g / L ammonium carbonate and 0.5g / L sodium cyanide are added for selective heap leaching. The heap height is 4m, and the heap leaching period is 2 months. The shower strength is 20L / (h·m 2 ), the leaching rate of gold is 89.4%, and the consumption of sodium cyanide is 1.9kg / t ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com