Method for preparing phosphatidylserine abundant in polyunsaturated fatty acid

A technology of unsaturated fatty acid and phosphatidylserine, applied in the field of bioengineering, can solve the problems of high manufacturing cost, difficult industrialization, complex device structure, etc., and achieve the effects of easy large-scale production, few reaction by-products, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

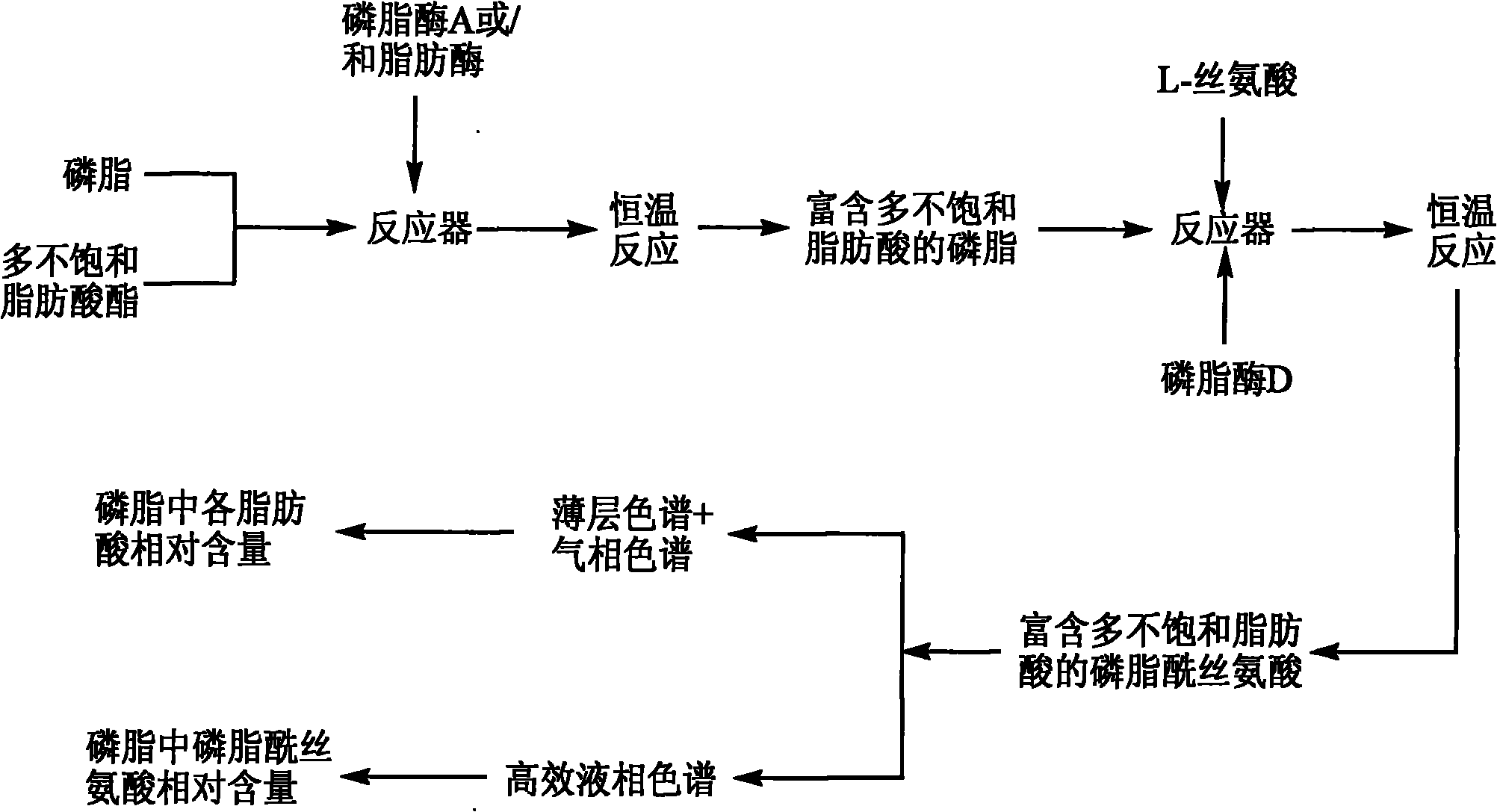

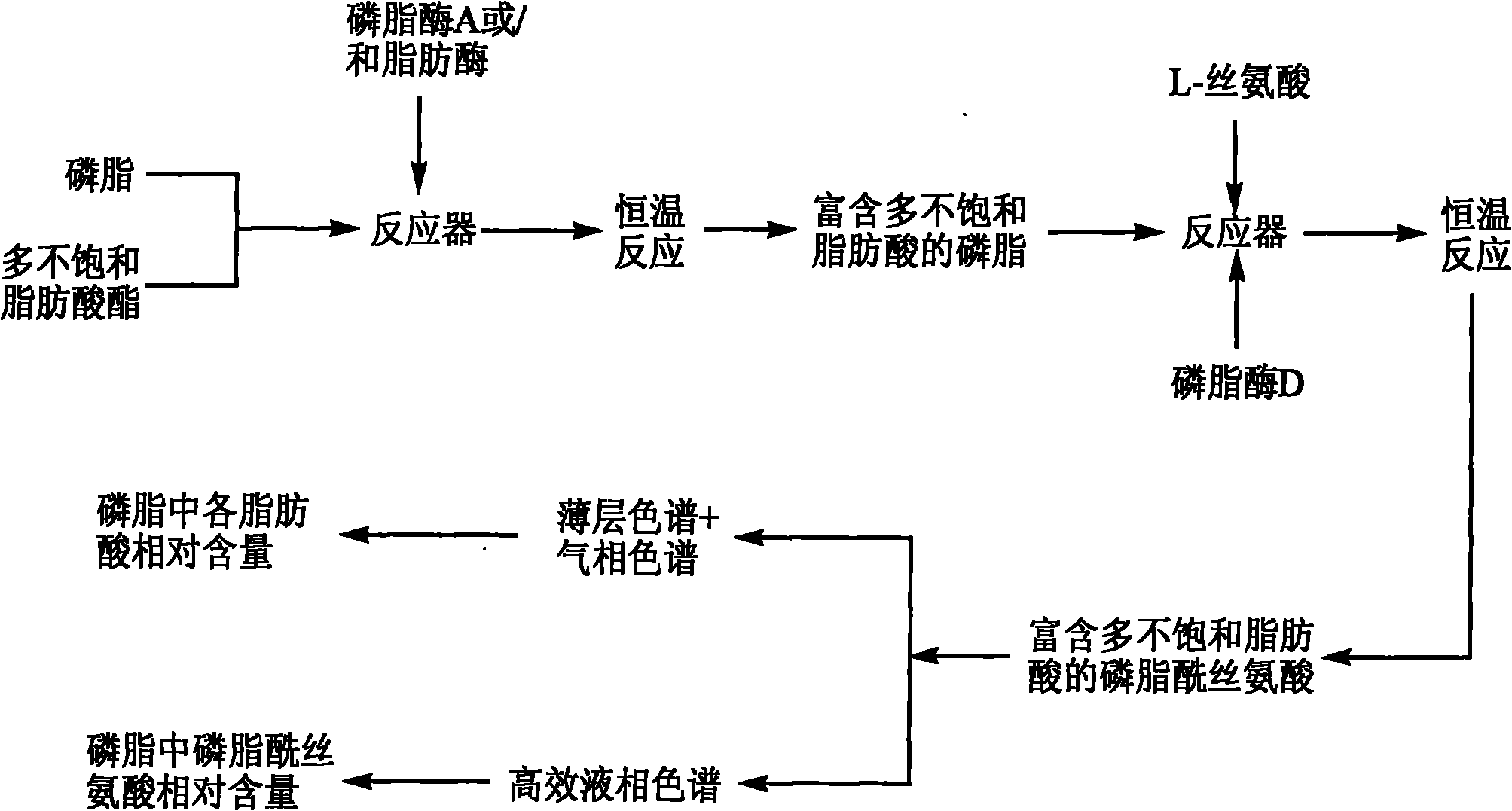

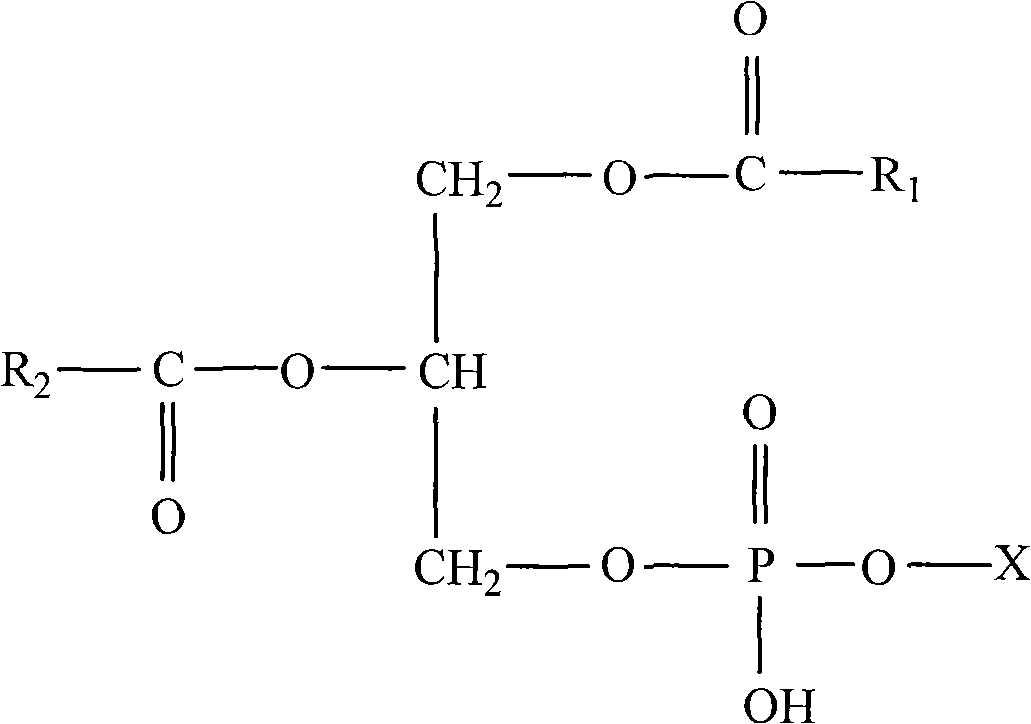

Method used

Image

Examples

Embodiment 1

[0043] Weigh 0.75g egg yolk lecithin (purity ≥ 99%) and 0.918g gamma-linolenic acid ethyl ester (containing gamma-linolenic acid 72.72%) in a flat-bottomed glass sample bottle with a stopper, fill the bottle with nitrogen, at 50 ° C Stir to make lecithin completely dissolved in ethyl ester, then add phospholipase A by 10wt% 1 ( Ultra), seal the sample bottle, fill the bottle with nitrogen gas again, and stir the reaction at 50°C for 10h. After the reaction is completed, add 1.0mol / L HCl to the sample to terminate the reaction, and then add an equal amount of 1.0mol / L NaOH And, then add 18 mL of 0.2 mol / L sodium acetate buffer solution (pH5.6) containing 3.4 mol / L of L-serine and 4.8 U of Streptomyces phospholipase D to the sample, at 30 ° C, 200 r / min After the reaction was completed for 16 hours, 1.0 mol / L HCl was added to the sample to terminate the reaction. Take a small amount of sample, add an appropriate amount of chloroform solution, then centrifuge the sample at 400...

Embodiment 2

[0045] Weigh 1.25g soybean lecithin (purity ≥ 60%) and 1.05g fish oil ethyl ester (containing EPA9%, DHA42%) in a flat-bottomed glass sample bottle with a stopper, fill the bottle with nitrogen, and stir at 55°C to make the eggs Phospholipids are completely dissolved in ethyl ester, and phospholipase A is added at 20 wt% 1 ( Novo), seal the sample bottle, fill the bottle with nitrogen again, stir and react at 55°C for 10h, after the reaction is completed, add 1.0mol / L HCl to the sample to terminate the reaction, and then add an equivalent amount of 1.0mol / L NaOH And, then add 20 mL of 0.11 mol / L sodium acetate buffer solution (pH5.6) containing 2.0 mol / L of L-serine and 10 U of soybean phospholipase D to the sample, and react at 28 °C and 200 r / min for 18 h , after the reaction was completed, 1.0 mol / L HCl was added to the sample to terminate the reaction. Take a small amount of sample, add an appropriate amount of chloroform solution, then centrifuge the sample at 4000r / mi...

Embodiment 3

[0047] Weigh 0.95g of soybean lecithin (purity ≥ 90%) and 3.60g of fish oil (containing DHA and EPA50%) in a flat-bottomed glass sample bottle with a stopper, fill the bottle with nitrogen, and stir at 50°C to completely dissolve the lecithin In the fish oil, add Novozym 435 at 10wt%, seal the sample bottle, fill the bottle with nitrogen gas again, stir and react at 50°C for 14h, after the reaction is completed, filter to remove the enzyme, and then add 30mL of L containing 2.0mol / L to the sample - 0.22mol / L sodium acetate buffer solution (pH5.6) of serine and 6U of phospholipase D (derived from coryneform bacteria), reacted at 30°C and 200r / min for 24h, after the reaction was completed, add 1.0 mol / L HCl to terminate the reaction. Take a small amount of sample, add an appropriate amount of chloroform solution, then centrifuge the sample at 4000r / min for 10min, take the chloroform layer, analyze the sample, use TLC-GC to detect the fatty acid composition of phospholipids, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com