Process for waste and old tyre rubber stress induced desulphurization reaction

A waste tire rubber and process technology, which is applied in the field of improved stress-induced desulfurization reaction of waste tire rubber, can solve the problems of the reduction of the tensile strength of the revulcanized material, the influence of the performance of the reclaimed rubber material, the breakage of the molecular main chain, etc., so as to improve the selectivity Probability of fracture, automated desulfurization production, effect of modified compatibility properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 (desulfurization reaction of tire rubber powder using sec-butanol as accelerator and performance of blended SBR rubber), tire rubber powder (GTR) 20 mesh, provided by Jiangsu Tongjiang Plastic Co., Ltd., obtained through thermogravimetric analysis: rubber content The carbon black content is 42.9%, the carbon black content is 33.2%, the ash content is 18.3%, and the volatile content is 5.6%.

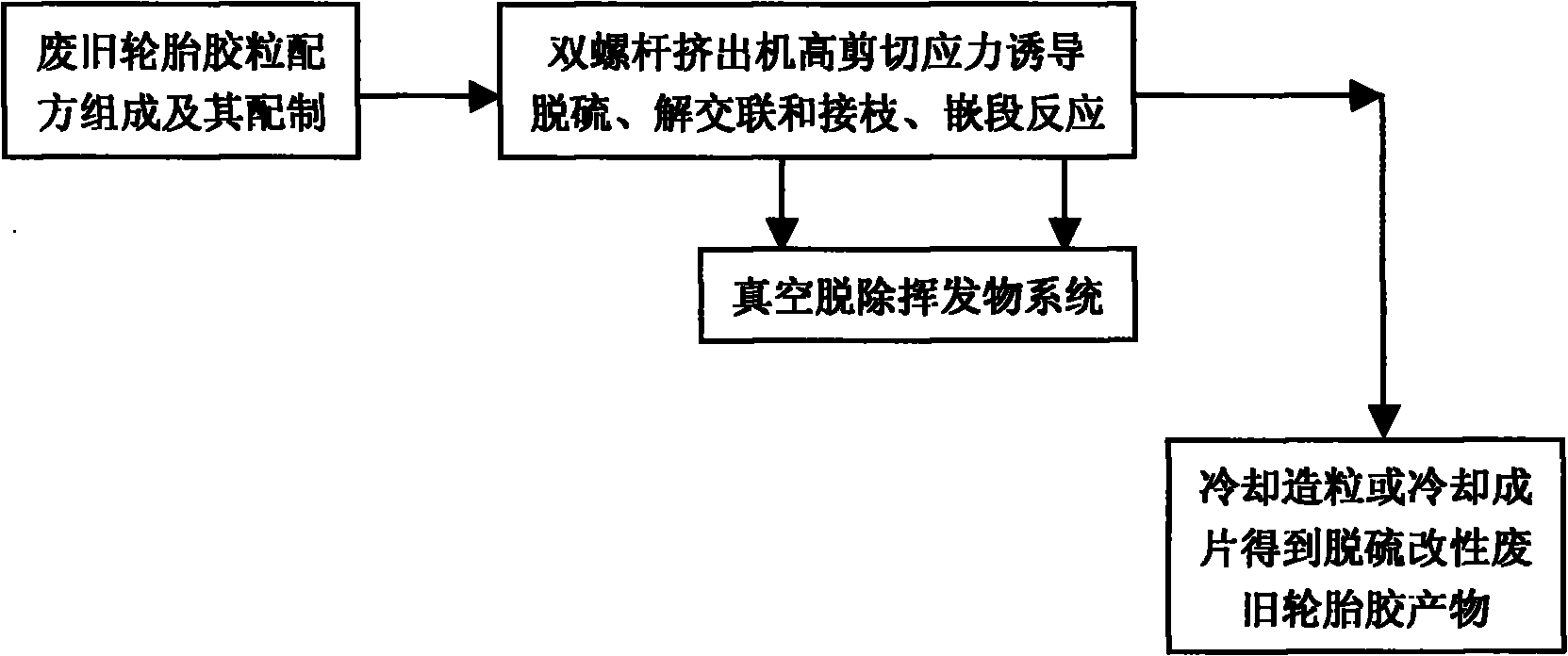

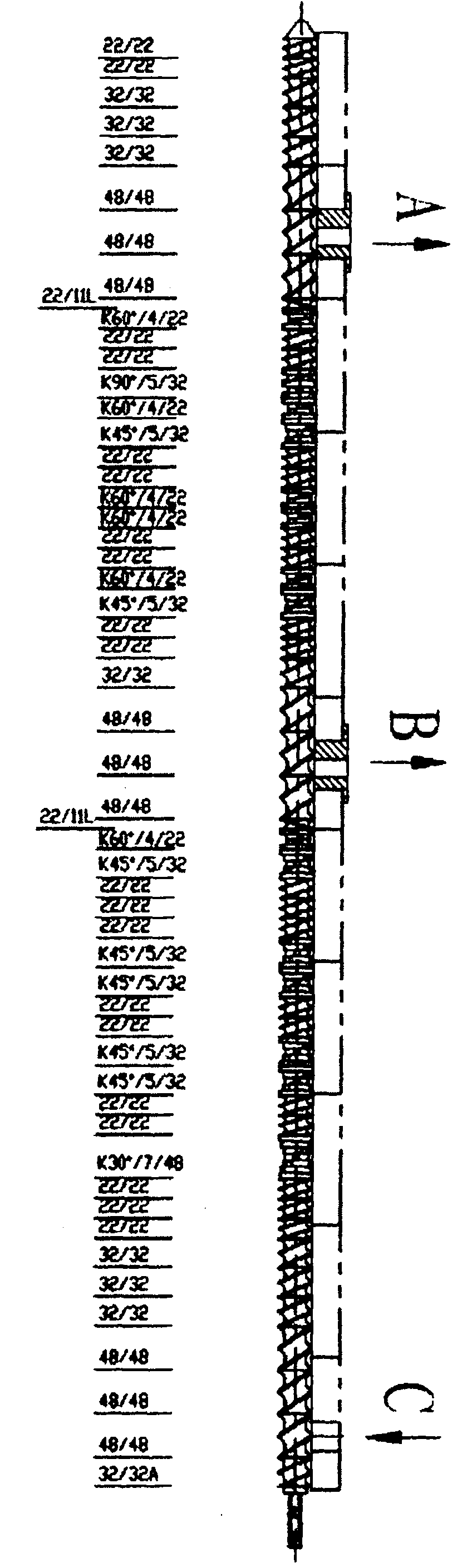

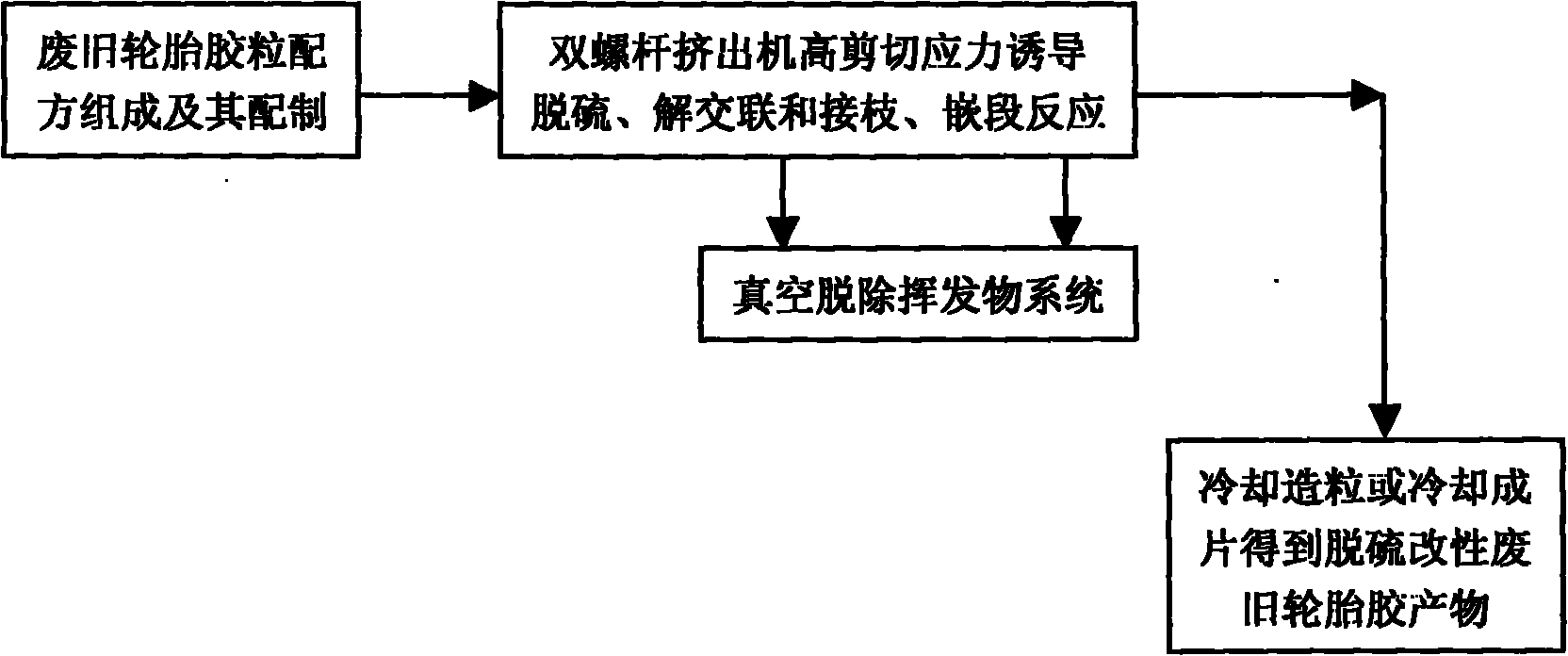

[0033] Mix 800 grams of above-mentioned tire rubber powder with 200 grams of EPDM (NDR4770 U.S. Dupont-Taoshi company product), 50 grams of sec-butanol, 2 grams of antioxidant 1010 and 1.5 grams of calcium stearate; In a three-stage co-rotating twin-screw extruder with an aspect ratio of 35mm and an aspect ratio of 45 (manufactured by Nanjing Keya Machinery Equipment Co., Ltd., please refer to the attached drawing for the extrusion process and screw combination diagram of the extrusion device. figure 1 And attached figure 2 ); control the extrusion reaction temperature ...

Embodiment 2

[0058] Embodiment 2 (select car tire tread rubber powder and use sec-butanol as the desulfurization reaction of tire rubber powder as desulfurization accelerator and the properties of blended SBR rubber): the tire rubber powder is changed to Yangzhou Lvhuan Waste Rubber Recycling Co., Ltd. The provided 10 mesh car tire tread rubber powder (GTR) is obtained through thermogravimetric analysis: the rubber content is 46.8%, the carbon black content is 33.8%, the ash content is 12.1%, and the volatile matter content is 7.3%. Others are the same as in Example 1. The gel content of the obtained desulfurized tire rubber product is 29.3%, the tensile strength of the vulcanized rubber sheet is 18.5MPa, the elongation at break is 887.6%, the tear strength is 94.8kN / m, and the Shore A hardness is 62.

[0059] The gel content of the product of Example 2 is 29.3% obviously lower than the gel content of 40.7% of the product of Example 1, indicating that the cross-linking density of the car t...

Embodiment 3

[0065] Embodiment 3 (select car tire tread rubber powder and adopt tert-butanol as desulfurization accelerator tire rubber desulfurization reaction and blending SBR rubber performance): the desulfurization reaction accelerator is changed from sec-butanol to tert-butanol, Others are the same as in Example 2. The gel content of the obtained desulfurized tire rubber product is 32.6%, the tensile strength of the vulcanized rubber sheet is 16.1MPa, the elongation at break is 864.5%, the tear strength is 86.7kN / m, and the Shore A hardness is 60.

[0066] By fixing the extrusion reaction temperature and changing the screw speed, the comparative data of Example 3 under different screw speed conditions can be obtained as shown in table 6:

[0067]Table 6 The effect of screw speed on the properties of DGTR / EPDM and the mechanical properties of SBR / (DGTR / EPDM) vulcanized blends

[0068]

[0069] *The desulfurization reaction temperature is 240°C, and the desulfurization accelerator i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com