Marsh gas oxygen-enriched combustion-biogas slurry denitrification system and method

A technology of oxygen-enriched combustion and biogas slurry, which is applied in the field of biogas flue gas denitrification, can solve problems such as difficult to achieve biogas flue gas denitrification, achieve the effects of optimizing biogas combustion effect, promoting biogas combustion, and increasing biogas combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

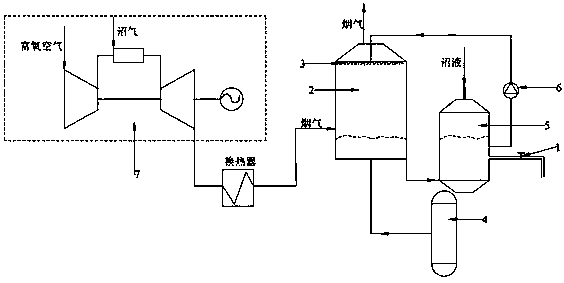

[0026] Embodiment 1: as figure 1 As shown, a biogas oxygen-enriched combustion-biogas slurry denitrification system includes a biogas generator set 7, a denitrification tank 2, a compressed air bottle 4, and a biogas slurry storage tank 5. The gas enters the bottom of the denitrification tank 2 through the flue gas pipeline, and the outlet of the compressed air bottle 4 communicates with the air inlet at the bottom of the denitrification tank 2 through the air pipeline. The gas outlet and the flue gas outlet are located above the atomizing nozzle 3. The liquid outlet at the bottom of the denitrification tank 2 is connected to the bottom liquid inlet of the biogas slurry storage tank 5 through a liquid delivery pipe. The outlet I communicates with the atomizing nozzle 3 on the top of the denitrification tank 2 through the biogas slurry delivery pipeline. The biogas slurry delivery pipeline is provided with a biogas slurry pump 6, and the top of the biogas slurry storage tank 5 ...

Embodiment 2

[0034] Embodiment 2: The biogas oxygen-enriched combustion-biogas slurry denitrification system in this embodiment is the same as that in Embodiment 1;

[0035] A biogas oxygen-enriched combustion-biogas slurry denitrification method, using a biogas oxygen-enriched combustion-biogas slurry denitrification system, the specific steps are as follows:

[0036] (1) Pass the biogas through the biogas pipeline to the internal combustion engine of the biogas generator set for oxygen-enriched combustion to generate electricity; the oxygen-enriched air in the oxygen-enriched combustion combustion-supporting oxygen-enriched air has an oxygen volume content of 30%;

[0037] (2) Step (1) The flue gas from the oxygen-enriched combustion is passed into the bottom of the denitrification tank through the flue gas pipe, and the air in the compressed air bottle is passed into the bottom of the denitrification tank through the air pipe; the flue gas flow rate is 5.1m 3 / min, the air flow rate is ...

Embodiment 3

[0041] Embodiment 3: The biogas oxygen-enriched combustion-biogas slurry denitrification system in this embodiment is the same as that in Embodiment 1;

[0042] A biogas oxygen-enriched combustion-biogas slurry denitrification method, using a biogas oxygen-enriched combustion-biogas slurry denitrification system, the specific steps are as follows:

[0043] (1) Pass the biogas through the biogas pipeline to the internal combustion engine of the biogas generator set for oxygen-enriched combustion to generate electricity; the oxygen-enriched air in the oxygen-enriched combustion combustion-supporting oxygen-enriched air has an oxygen volume content of 33%;

[0044] (2) Step (1) The flue gas from the oxygen-enriched combustion is passed into the bottom of the denitrification tank through the flue gas pipeline, and the air in the compressed air bottle is passed into the bottom of the denitrification tank through the air pipeline; the flue gas flow rate is 5.2m 3 / min, the air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com