Process for production of surface-modified rare earth sintered magnets and surface-modified rare earth sintered magnets

A technology for surface modification and sintering of magnets, which is used in the manufacture of inductors/transformers/magnets, permanent magnets, magnetic materials, etc. It can solve the problems of being easily oxidized and corroded, and achieve the effect of reducing and suppressing the magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

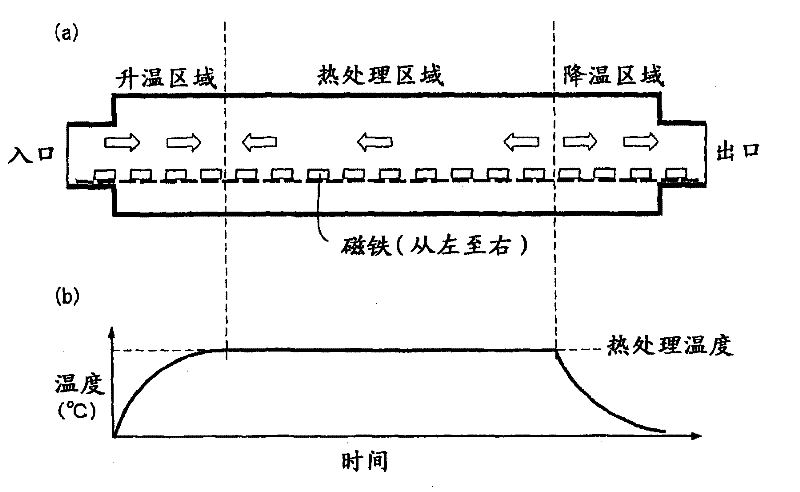

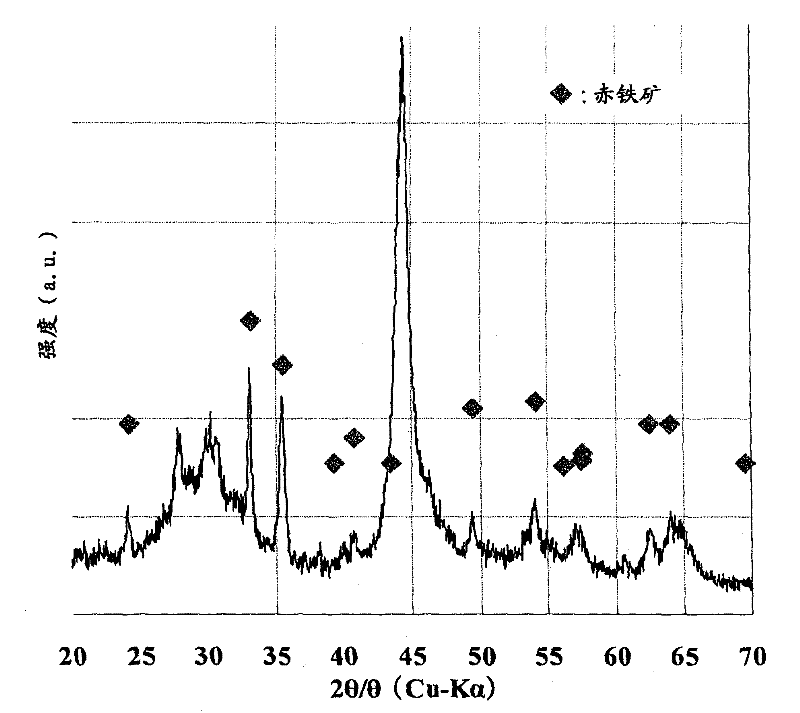

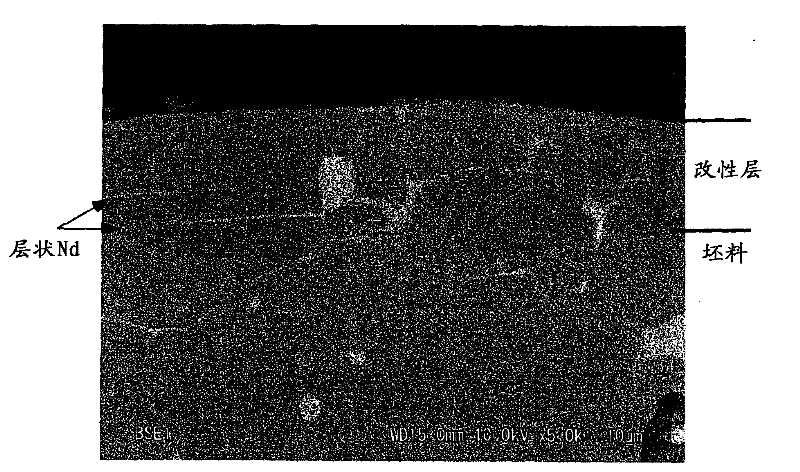

[0067] After washing with alcohol, the magnet test pieces were subjected to aging treatment at 490°C for 2.5 hours in vacuum. Under the atmosphere of 33.3), heat treatment was carried out at 400° C. for 15 minutes to obtain a surface-modified magnet test piece. In addition, the temperature rise of the magnet test piece from room temperature to the heat treatment temperature is carried out at a rate of about 900°C / hour in an atmosphere (oxygen partial pressure 20000Pa, water vapor partial pressure 12.9Pa) at a dew point of -40°C. (heating time 25 minutes). In addition, the temperature drop after the heat treatment was also performed in the same atmosphere. After the magnet test piece was embedded in resin and ground, a sample was prepared using an ion beam cross-section processing device (SM 09010: manufactured by JEOL Ltd.), and the cross-sectional observation was performed with a digital microscope (VHX-200: manufactured by Keyence Corporation). , the thickness of the modif...

Embodiment 2

[0069] With the magnet body test piece after alcohol washing, after adopting the same condition as embodiment 1 to carry out heat treatment, be 5Pa at oxygen partial pressure, water vapor partial pressure is 2.5 * 10 -3 Heat treatment was performed at 500° C. for 5 minutes in an atmosphere of Pa, whereby a surface-modified magnet test piece was obtained. The magnet test piece was evaluated in the same manner as in Example 1. As a result, the thickness of the modified layer formed on the surface of the magnet test piece was about 5.5 μm, and its composition was the same as that of the surface-modified magnet obtained in Example 1. The modified layer in the bulk test piece was the same (Table 1).

Embodiment 3

[0071] For the magnet test piece washed with alcohol, when the oxygen partial pressure is 5Pa, the water vapor partial pressure is 2.5×10 -3 Under Pa atmosphere, heat treatment was carried out at 500°C for 5 minutes, and then heat treatment was carried out under the same conditions as in Example 1, thereby obtaining a surface-modified magnet test piece. The magnet test piece was evaluated in the same manner as in Example 1. As a result, the thickness of the modified layer formed on the surface of the magnet test piece was about 4.1 μm, and its composition was the same as that of the surface-modified magnet obtained in Example 1. The modified layer in the bulk test piece was the same (Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com