Special machine for piston ring numerical-control milling plates

A special machine tool and CNC milling technology, which is applied to milling machine equipment, milling machine equipment details, chucks, etc., can solve the problems of piston ring flatness, poor parallelism, roughness, damage to the piston ring line, and high light leakage rate of piston rings, etc., to achieve Improve processing accuracy, reduce scrap rate, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

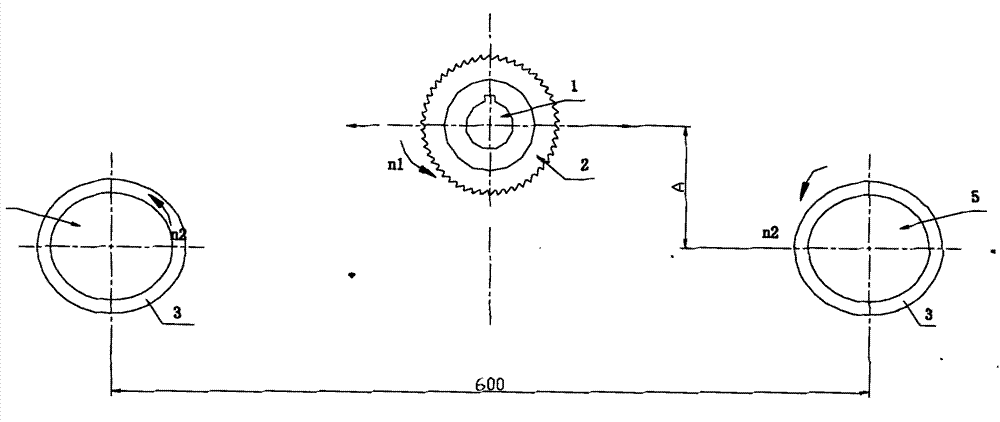

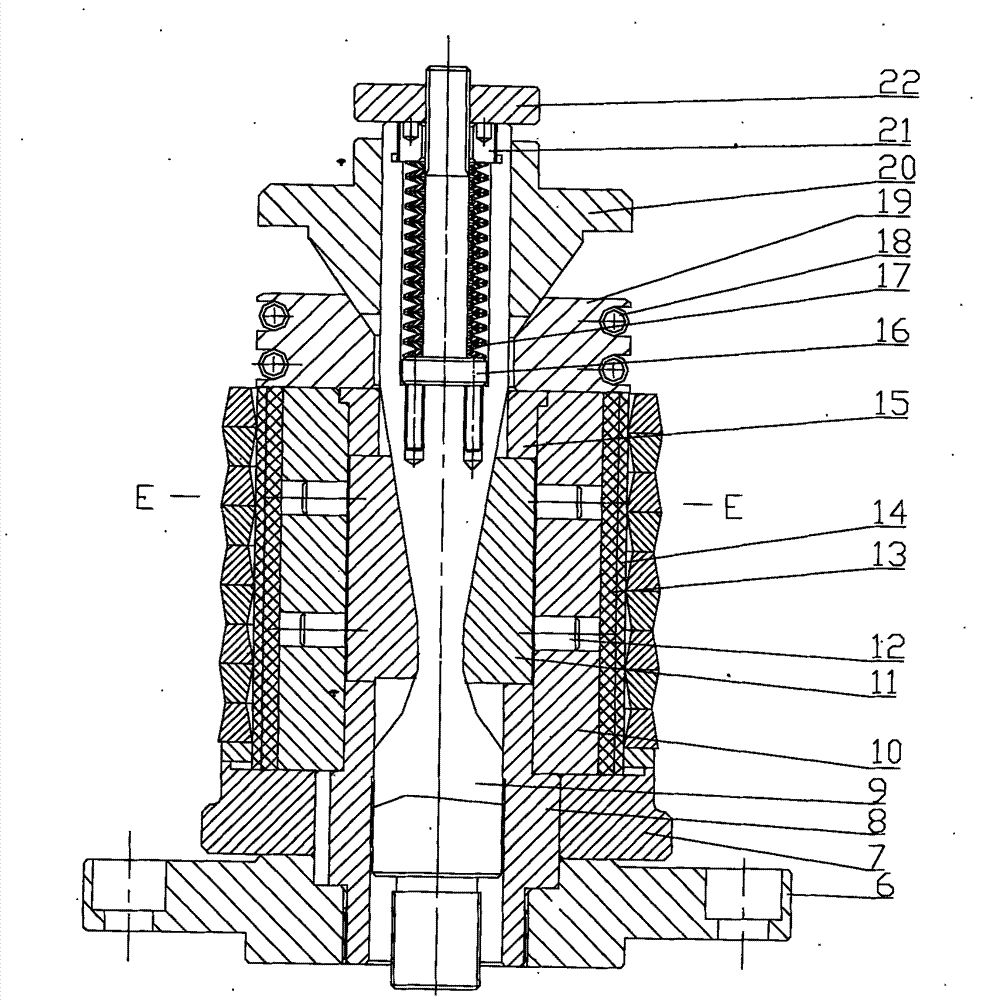

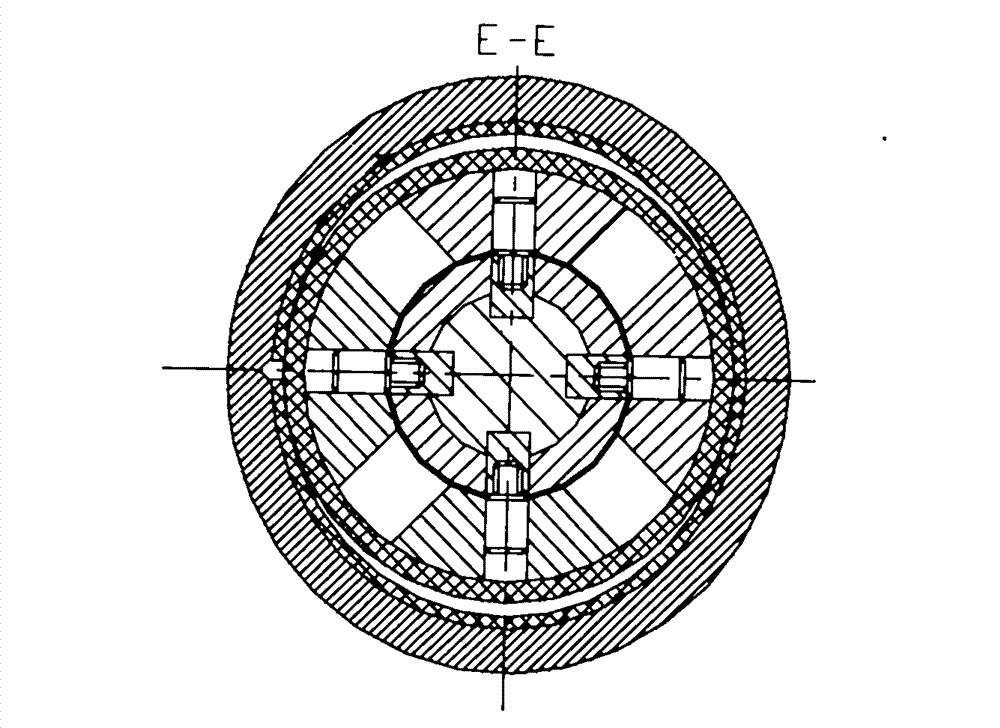

[0034] see Figure 1 to Figure 6 , the special machine tool for piston ring CNC milling and slicing, including a bed, a workpiece fixture part, a cutting tool part and a power transmission device, is characterized in that the fixture part is provided with a semi-rigid and semi-flexible externally stretched fixture, and its structure is: a pull rod 9 , the outside of the pull rod 9 is provided with guide sleeves 8, 7 and its fixed disk 6, the pull rod 9 is provided with a cam structure, and the cam structure (which can be 3 oblique chute structures) is at least provided with 3 petals and cams. The externally expanded slider with the type structure is equipped with an elastic material tension sleeve that can tighten the piston ring outside the externally expanded slider; and a side-by-side combined milling cutter is provided. The elastic material tensioner has an elastic inner sleeve 13 and an elastic outer sleeve 14, the elastic inner sleeve 13 is made of rubber or plastic, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com