Active carbon-based material and preparation method thereof

A technology of carbon-based materials and base materials, applied in the field of activated carbon-based materials and their preparation, can solve the problems of low energy density and power density of supercapacitors, limited space for increasing specific surface area, and decreased volume specific capacity, etc., to achieve good heat conduction Effects with electrical conductivity, high energy density and power density, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Dissolve 1.86mL aniline (AN) in 25mLH 2 SO 4 Dissolve 1.14g of ammonium persulfate (APS) in 50mL of distilled water or deionized water to form solution A ([APS] / [AN]=1∶4); (2) Transfer solution A into the reaction flask Inside, add B to the reaction flask dropwise with stirring, after dropping, react at room temperature for 4 hours; (3) Collect the product in the reaction flask, and wash the product with water, ethanol or acetone several times until the washing liquid is neutral; (4) The washed product was vacuum dried at 60°C for 48 hours to obtain sulfuric acid-doped polyaniline; (5) in an inert gas N 2 Under protection, carbonize polyaniline at 800℃ for 2h; (6) Activate the carbonized material prepared above in water vapor at 200℃ for 2h, and cool to room temperature to obtain activated carbon-based doped with N, O, and S atoms. material. After elemental analysis and X-ray photoelectron spectroscopy (XPS) test, the components and mass ratio content of the doped ac...

Embodiment 2

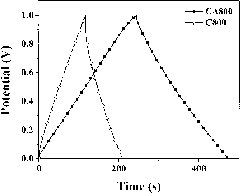

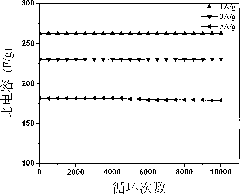

[0024] (1) Dissolve 1.86mL aniline in 25mLH 2 SO 4 Dissolve 2.28g of ammonium persulfate in 50mL of distilled water or deionized water to form solution A ([APS] / [AN]=1∶2); (2) Put solution A and solution B in the reaction flask After mixing and stirring rapidly for 1 min, let it stand for 10 hours at room temperature; (3) Collect the product in the reaction flask, and wash the product with water, ethanol or acetone several times until the washing liquid is neutral; (4) The product after washing Vacuum drying at 60°C for 48h to obtain doped polyaniline; (5) in inert gas N 2 Under protection, carbonize polyaniline at 800℃ for 2h; (6) Put the carbonized material prepared above at 10℃~40℃ 1mol·L -1 Soaking in nitric acid solution for 24 hours for activation treatment, and then washing, drying and ball milling to obtain activated carbon material. The code of the unactivated sample prepared in this example was C800, and the code of the activated sample was CA800.

[0025] The electrode...

Embodiment 3

[0027] (1) Mix 20mmol of aniline and 20mmol of HAc with ultrasound for about 2min to obtain A; (2) Dissolve 25mmol APS in 20mmol of HAc, ultrasonically dissolve and mix thoroughly for about 2min to obtain B. (3) Mix A and B ultrasonically at room temperature for about 2 minutes, and then stand at room temperature to react for 8 hours. (3) Collect the reaction product and wash the product with water until the washing solution is neutral; (4) Dry the washed product in vacuum at 60°C for 24 hours to obtain doped polyaniline; (5) In an inert gas N 2 Carbonize polyaniline at 800°C for 4h under protection; (6) After mixing the carbonized material prepared above and sodium hydroxide uniformly, activate it at 700°C under nitrogen protection for 2h (the mass ratio of carbon to NaOH is 2:1), After washing, drying and ball milling, activated carbon-based materials are obtained.

[0028] The electrode fabrication, supercapacitor assembly, and testing equipment in this embodiment are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com