Spray atomization technology of silver tin oxide material

A technology of silver tin oxide and spray atomization, which is applied in the direction of electrical components, circuits, electric switches, etc., can solve the problems of increased production costs, and achieve the effects of short production cycle, reduced production cost, and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

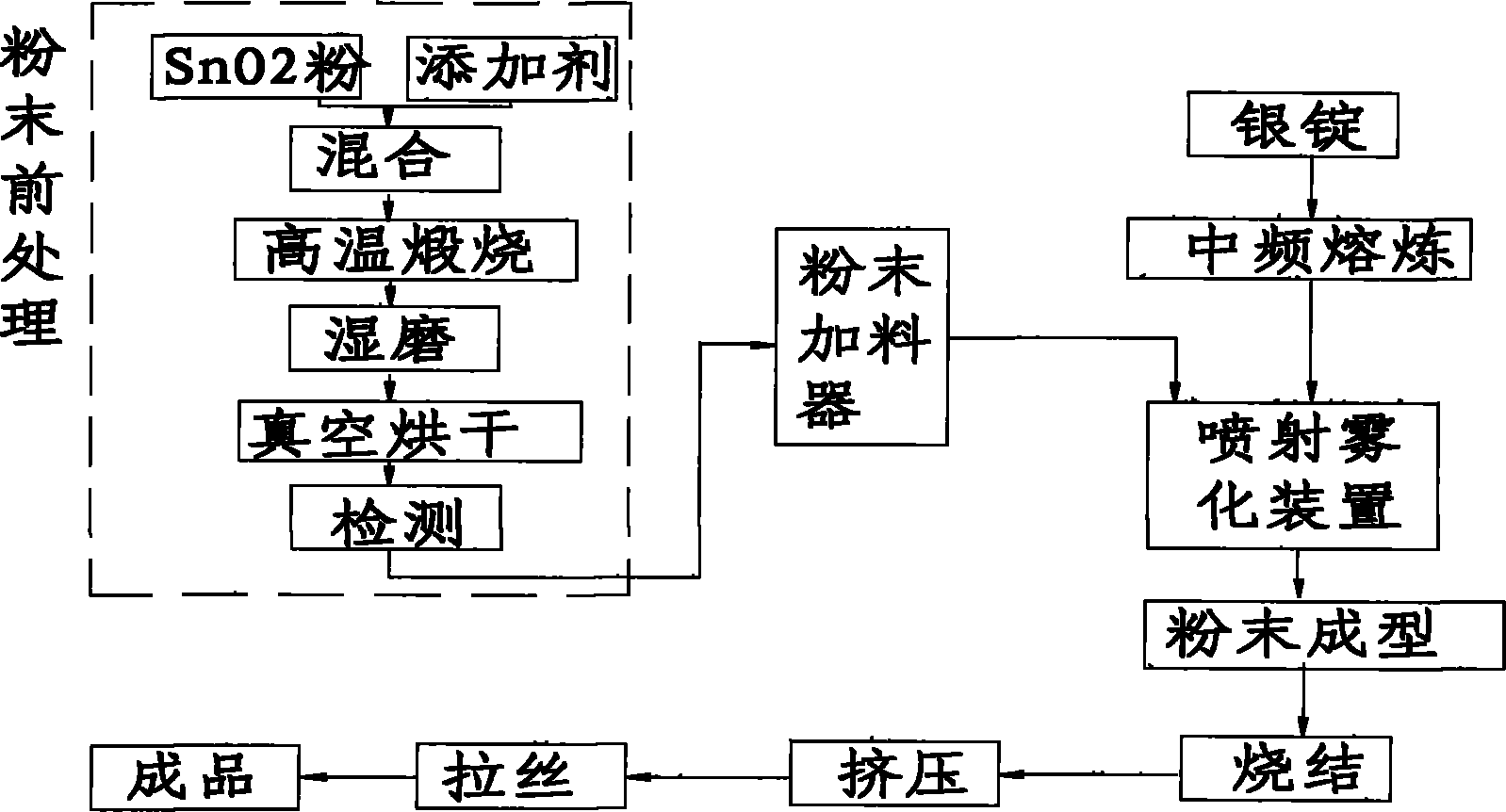

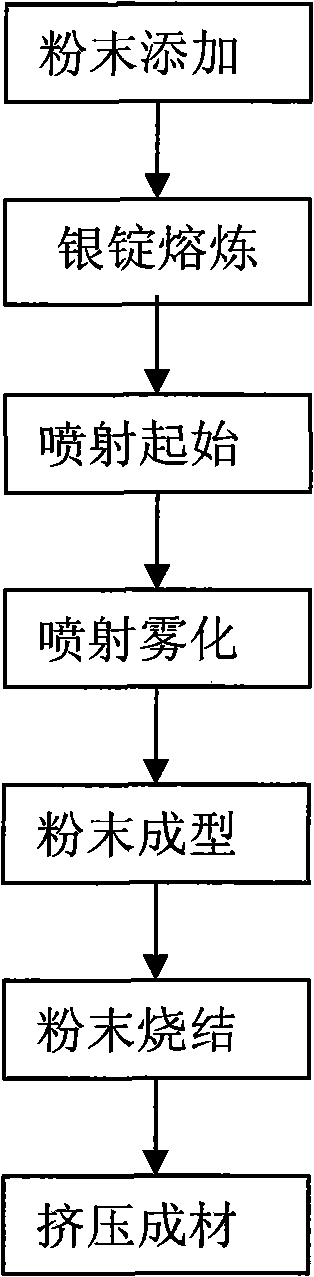

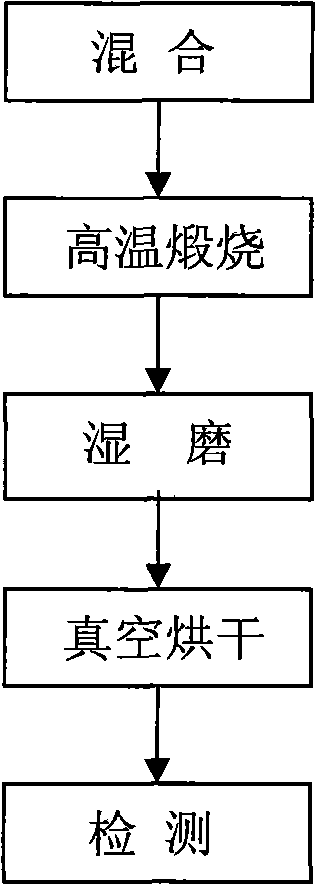

Method used

Image

Examples

Embodiment 1

[0057] Weigh 5 kg of SnO 2 Powder, add 0.3kg Bi 2 o 3 powder, ball milled in a planetary ball mill and mixed for 30 minutes, the mixed SnO 2 The powder is calcined in a high-temperature calciner. During calcination, it is kept at 100°C for 0.5 hours, at 520°C for 0.5 hours, and at 1100°C for 2 hours. Calcined SnO 2 The powder was wet milled in a stirring ball mill for 2 hours, and the SnO 2 The ratio of powder to water is 0.5, and the ball powder ratio is 3.0. SnO after wet milling 2 Powder detection of SnO with laser particle size analyzer 2 Powder particle size, guarantee D 50 From 0.5 micron to 0.8 micron, the particles smaller than 1 micron should be more than 90%, and the particles larger than 3 microns should be less than 3%. Dry the wet-milled SnO in a vacuum oven 2 pink.

[0058] Accurately weigh 3 kg of treated SnO 2 Dry powder, add to the powder feeder of the jet atomizer. Add 22 kg of pure silver ingots to the intermediate frequency crucible of the spray...

Embodiment 2

[0064] Weigh 5 kg of SnO 2 Powder, add 0.5 kg Sb 2 o 3 powder, ball milled in a planetary ball mill and mixed for 30 minutes, the mixed SnO 2 The powder is calcined in a high-temperature calciner. During calcination, it is kept at 400° C. for 0.5 hours, at 700° C. for 0.5 hours, and at 1150° C. for 2 hours; others are the same as in Example 1.

[0065] Metallographic testing, scanning electron microscopy and rivet processing performance analysis of the wire products show that the prepared wire products also have good structure uniformity and processing performance.

Embodiment 3

[0067] Weigh 3 kg of SnO 2 powder, added to an aqueous solution consisting of 0.4 kg of bismuth nitrate and 0.15 kg of copper nitrate, adding ammonia water at a high speed to a pH value between 5.5 and 6.5 to form a precipitate of bismuth and copper ions in the form of hydroxide, and deposit the precipitate in a vacuum oven The obtained powder was ball-milled in a planetary ball mill for 15 minutes and then calcined in a high-temperature calciner. During calcination, it was kept at 250°C for 1 hour, at 560°C for 1 hour, and at 1100°C for 2 hours; others were the same as in Example 1.

[0068] The rivet processing performance test is carried out on wire products with a diameter of φ1.4. The rivet specification is F3.0×1.5 (0.3), the rivet cracking rate is less than 0.3%, and the pinching cracking rate is less than 1%, which shows that the rivet processing performance of the wire is better than the implementation example one.

[0069] The results of scanning electron microscope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com