Preparation method of antioxidant product with stable performance

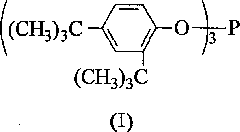

A technology of stable performance and antioxidant, applied in the field of preparation of antioxidant products with stable performance, can solve the quality and stability defects of antioxidant 168 products, unable to obtain high-purity antioxidant 168 products, and the occurrence of 168 products. Hydrolysis reaction and other problems, to achieve the effect of long-term anti-hydrolysis performance, good anti-oxidation performance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 558Kg (2.709mol) of 2,4-di-tert-butylphenol and 120Kg of xylene solvent into a 2000-liter esterification reaction kettle, raise the temperature to 80-85°C, reduce the pressure to -0.055--0.085MPa, and reflux dehydration for 50-60 Minutes, pass cooling water to cool down to 45-50°C, add catalyst pyridine 2.0Kg, add dropwise 126.0Kg (0.918mol) 2.95 / 1 phosphorus trichloride, dropwise time is 60-70 minutes. After adding phosphorus trichloride dropwise, keep warm at 50-52°C for 50-60 minutes. Raise the temperature to 130-135°C, and keep the temperature for 80-90 minutes. Adjust the reaction temperature to 125-130°C, reduce the pressure to -0.045--0.065MPa, reflux for 110-120 minutes, and the reaction ends. After the reaction, add 850Kg of xylene to the reaction kettle to completely dissolve the crude antioxidant 168 crystalline product, add 3Kg of triethylamine at 50-60°C, keep warm at 50-60°C, and stir for 30 minutes. Add 7.0Kg of filter aid diatomite, keep warm at 50...

Embodiment 2

[0035] Put 558Kg (2.709mol) of 2,4-di-tert-butylphenol and 120Kg of xylene solvent into a 2000-liter esterification reaction kettle, raise the temperature to 80-85°C, reduce the pressure to -0.055--0.085MPa, and reflux dehydration for 50-60 Minutes, pass cooling water to cool down to 45-50°C, add catalyst pyridine 2.5Kg, add dropwise 124.0Kg (0.903mol) 3 / 1 phosphorus trichloride, dropwise time is 60-70 minutes. After adding phosphorus trichloride dropwise, keep warm at 50-52°C for 50-60 minutes. Raise the temperature to 130-135°C, and keep the temperature for 60-65 minutes. Adjust the reaction temperature to 125-130° C., reduce the pressure to -0.045--0.065 MPa, reflux for 140-150 minutes, and the reaction ends. After the reaction, add 850Kg of xylene to the reaction kettle to completely dissolve the crude antioxidant 168 crystal, add 2.5Kg of triethylamine at 50-60°C, keep warm at 50-60°C, and stir for 30 minutes. Add 6.0Kg of filter aid diatomite, keep warm at 50-60°C, sti...

Embodiment 3

[0037] Put 558Kg (2.709mol) of 2,4-di-tert-butylphenol and 150Kg of xylene solvent into a 2000-liter esterification reaction kettle, raise the temperature to 80-85°C, depressurize to -0.055--0.085MPa, and reflux dehydration for 50-60 Minutes, pass cooling water to cool down to 45-50°C, add catalyst pyridine 2.2Kg, add dropwise 120.0Kg (0.874mol) 3.1 / 1 phosphorus trichloride, dropwise time is 60-70 minutes. After adding phosphorus trichloride dropwise, keep warm at 50-52°C for 50-60 minutes. Raise the temperature to 130-135°C, and keep the temperature for 140-150 minutes. Adjust the reaction temperature to 125-130° C., reduce the pressure to -0.045--0.065 MPa, reflux for 90-95 minutes, and the reaction ends. After the reaction is over, add 800Kg of xylene to the reaction kettle to completely dissolve the crude antioxidant 168 crystallization product, add 3.5Kg of triethylamine at 50-60°C, keep warm at 50-60°C, and stir for 30 minutes. Add 8.0Kg of filter aid diatomite, keep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com