Halogen-free high heat-conducting resin composition and resin coated copper foil

A resin composition and high thermal conductivity technology, applied in the field of resin-coated copper foil, can solve the problems of not mentioning the application of glue-coated copper foil, not having high thermal conductivity, complicated operation, etc., achieving good reliability, high thermal conductivity, The effect of high heat resistance and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

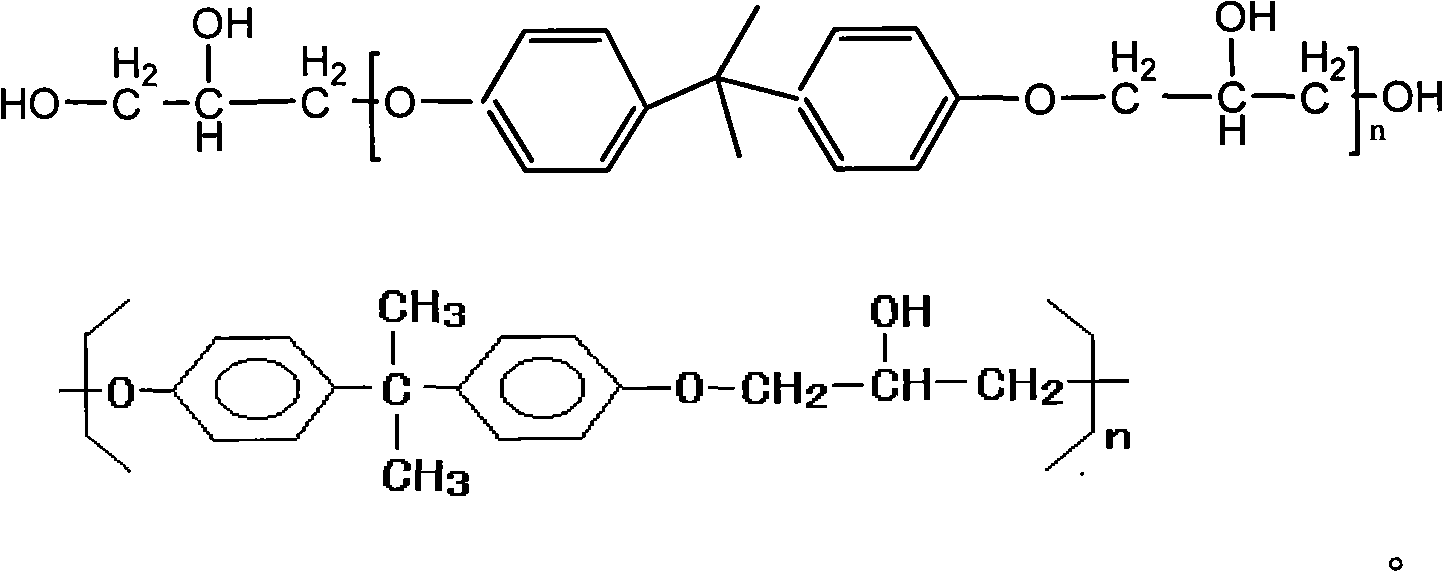

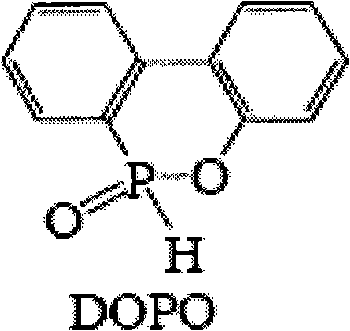

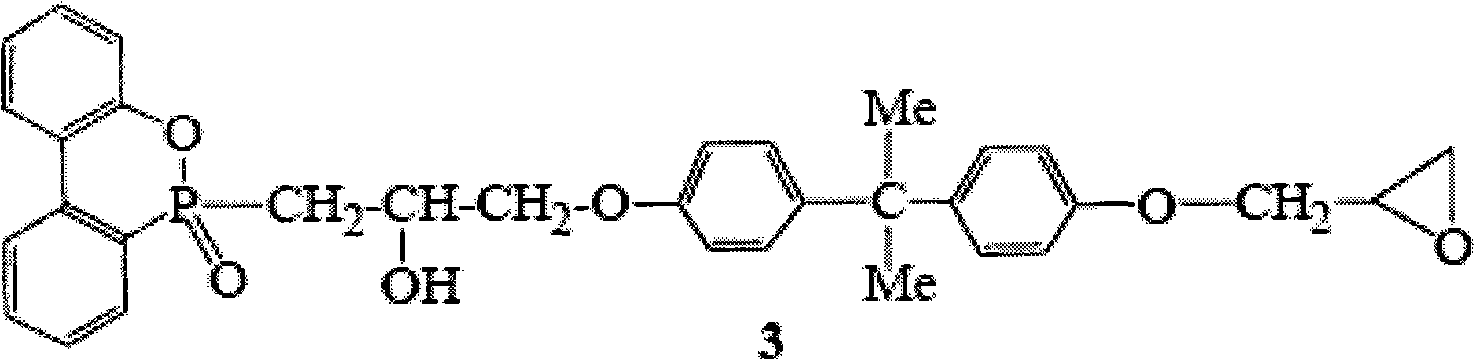

Method used

Image

Examples

Embodiment 1

[0053] 1. Dissolve 3 parts of amine curing agent and 2 parts of accelerator (2-MI) with an appropriate amount of dimethylformamide (DMF) and butanone (MEK) mixed solvent (1:1), and stir for more than 60 minutes .

[0054] 2. Then add phosphorus-containing epoxy resin, phenolic resin, UV-blocking multifunctional epoxy resin, and pre-treated alumina preform in a solid weight ratio of 30:15:5:50, and stir for more than 4 hours. Mix well and evenly to form a halogen-free high thermal conductivity resin composition with a solid content of 70%.

[0055] Coat the above resin composition on the roughened surface of the electrolytic copper foil with a nominal thickness of 35 microns, dry it, and bake it in an oven at 150°C for 3-5 minutes to obtain a resin-coated copper foil with a resin layer in a semi-cured state .

Embodiment 2

[0057] A resin-coated copper foil was produced in the same manner as in Example 1 except that the ratios of the resin mixture and the curing accelerator used in Example 1 were changed.

[0058] 1. Dissolve 3 parts of amine curing agent and 2 parts of accelerator (2-MI) with an appropriate amount of dimethylformamide (DMF) and butanone (MEK) mixed solvent (1:1), and stir for more than 60 minutes .

[0059] 2. Then add phosphorus-containing epoxy resin, phenolic resin, UV blocking multi-functional epoxy resin, and pre-treated alumina preform in a solid weight ratio of 10:35:5:50, and stir for more than 4 hours. Mix well and evenly to form a halogen-free high thermal conductivity resin composition with a solid content of 70%.

[0060] Coat the above resin composition on the roughened surface of the electrolytic copper foil with a nominal thickness of 35 microns, dry it, and bake it in an oven at 150°C for 3-5 minutes to obtain a resin-coated copper foil with a resin layer in a s...

Embodiment 3

[0062] A resin-coated copper foil was produced in the same manner as in Example 1 except that the ratios of the resin mixture and the curing accelerator used in Example 1 were changed.

[0063] 1. Dissolve 3 parts of amine curing agent and 2 parts of accelerator (2-MI) with an appropriate amount of dimethylformamide (DMF) and butanone (MEK) mixed solvent (1:1), and stir for more than 60 minutes .

[0064] 2. Then add phosphorus-containing epoxy resin, phenolic resin, UV-blocking multifunctional epoxy resin, and pre-treated alumina preform in a solid weight ratio of 20:8:2:70, and stir for more than 4 hours. Mix well and evenly to form a halogen-free high thermal conductivity resin composition with a solid content of 70%.

[0065] Coat the above resin composition on the roughened surface of the electrolytic copper foil with a nominal thickness of 35 microns, dry it, and bake it in an oven at 150°C for 3-5 minutes to obtain a resin-coated copper foil with a resin layer in a sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com