Preparation method and application of acrylate heterozygotic emulsion

A technology of acrylate and alkyl acrylate, applied in the field of preparation of acrylate hybrid emulsion, which can solve the problem of low hydroxyl value of hydroxyacrylate emulsion, high emulsifier content, poor emulsification ability of hydrophilic modified curing agent, etc. problems, to achieve the effect of good mechanical properties, dense coating structure and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

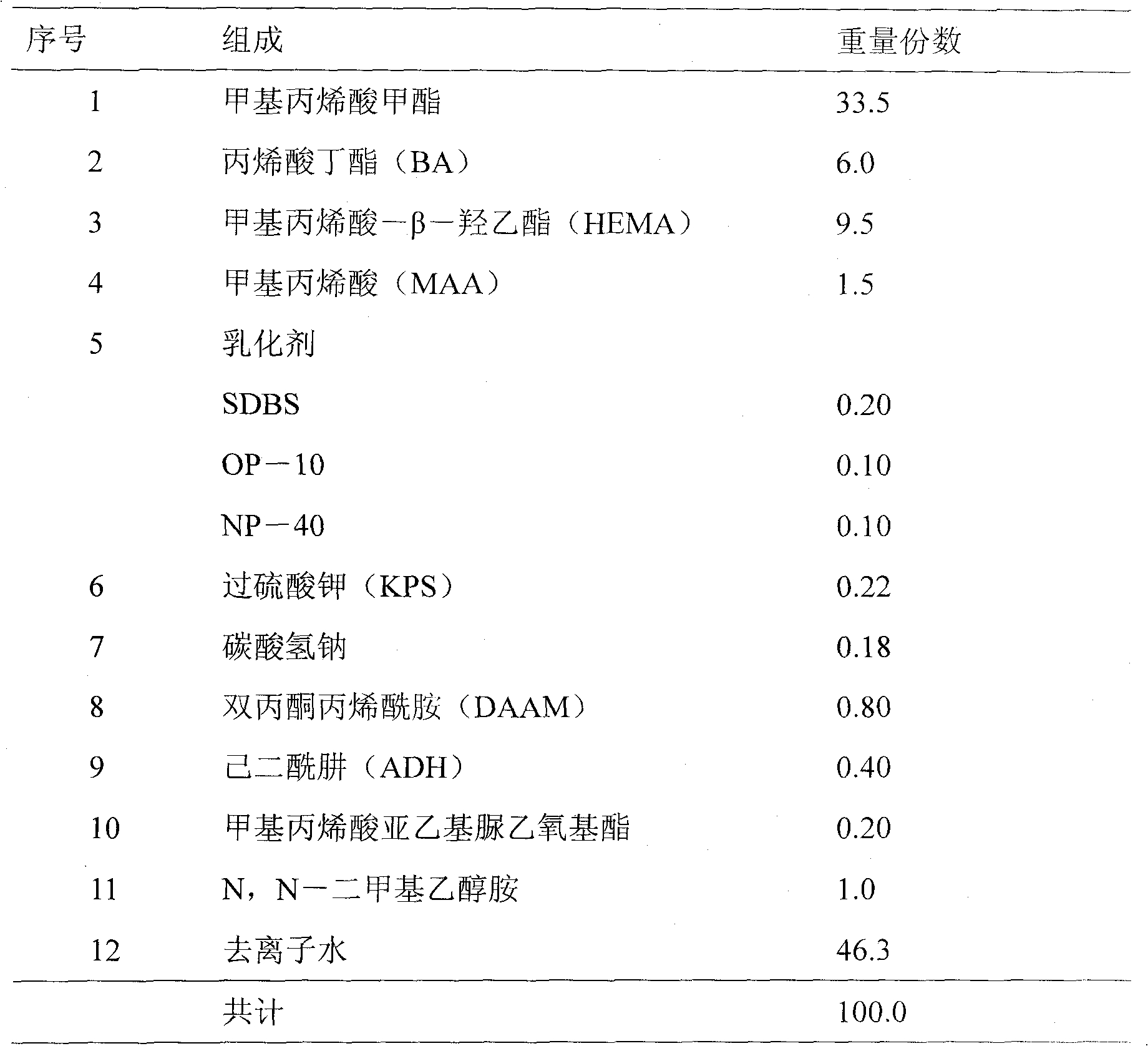

[0069] The formula of acrylate hybrid emulsion (PAH, hydroxyl value=99mgKOH / g) is shown in Table 1:

[0070] Table 1

[0071]

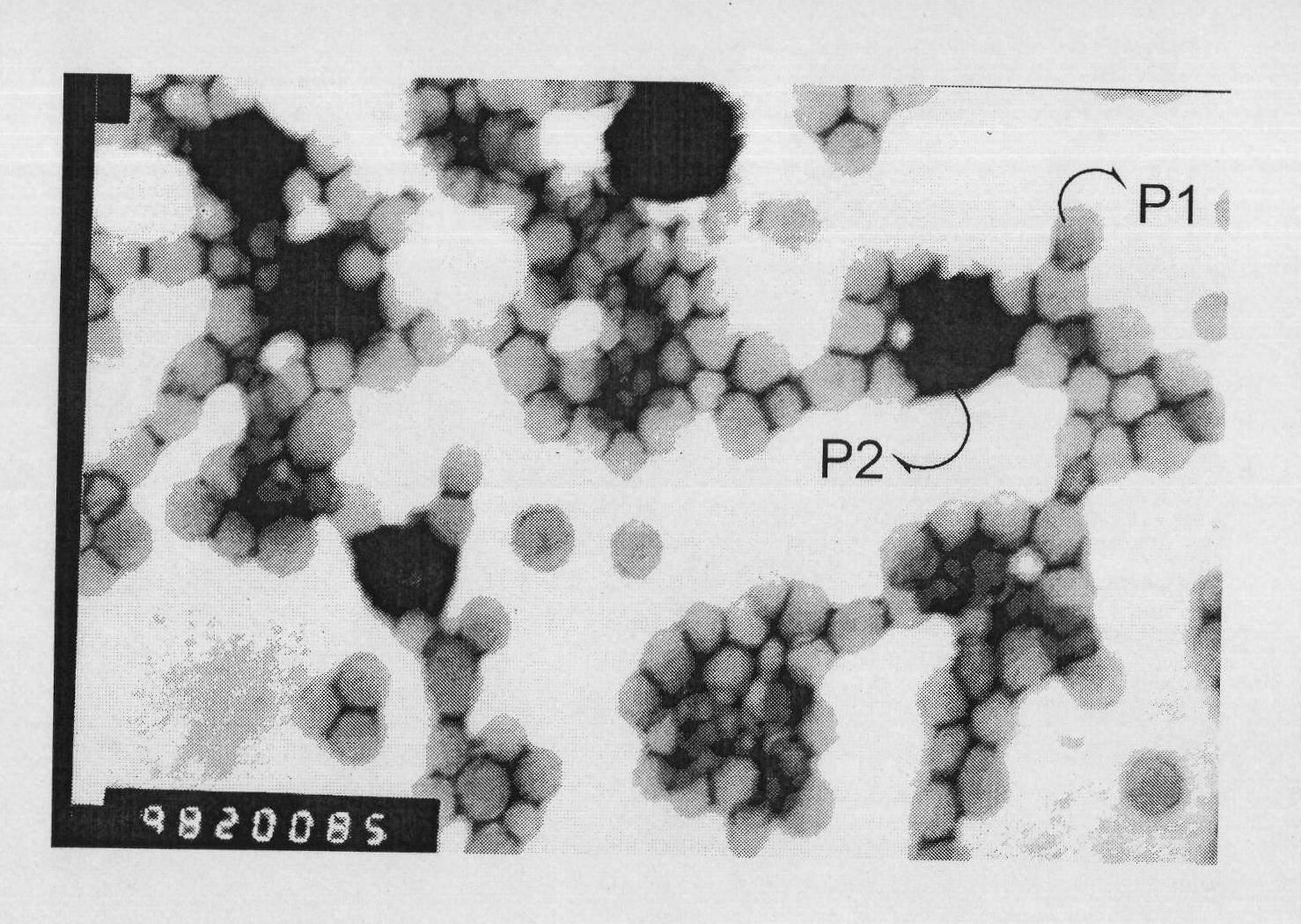

[0072] Add 0.4 parts of emulsifier, 0.18 parts of buffer, and 46.3 parts of deionized water into the reactor, raise the temperature to 75°C, stir for 30 minutes, and dropwise add 0.1 parts of methacrylic acid, 1 part of butyl acrylate and 3 parts of methacrylic acid The mixed monomer of methyl ester, add dropwise the aqueous solution (weight fraction is 5%) that contains 0.02 part of initiator simultaneously, add dropwise in half an hour, treat that the emulsion is blue phase and stable half an hour, obtain seed emulsion, keep reaction system temperature at 80°C, then drop the first polar monomer mixture into the seed emulsion to prepare polymer latex particles P 1 , the composition of the first polar monomer mixture is 20.5 parts of methyl methacrylate, 2.5 parts of butyl acrylate, 1.4 parts of methacrylic acid and 2 parts of β-hydroxyethyl metha...

Embodiment 2

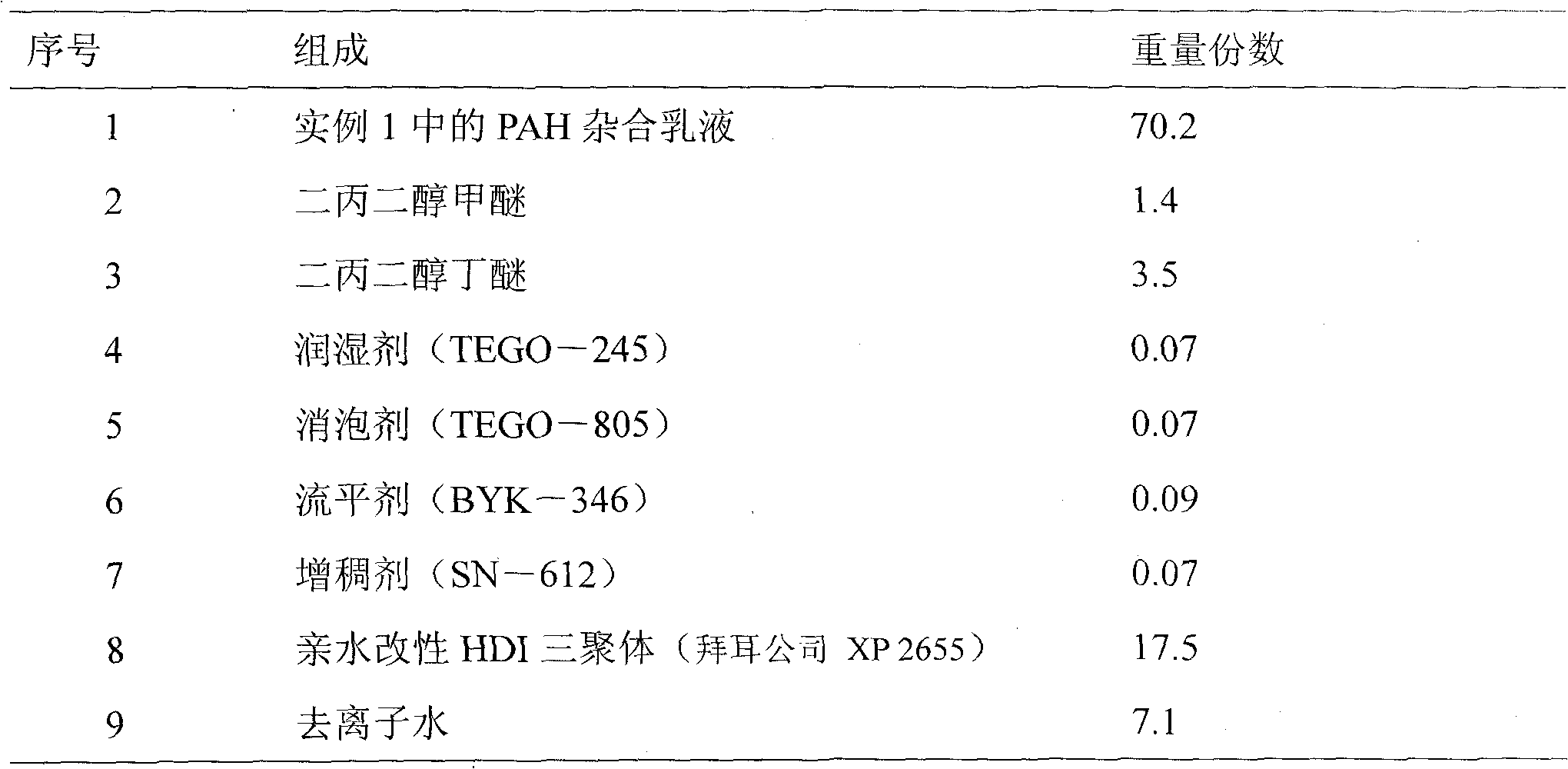

[0075] Using the acrylate hybrid emulsion prepared in Example 1, a waterborne two-component polyurethane coating (2K-WPU) formulation was prepared as shown in Table 2.

[0076] Table 2

[0077]

[0078] The preparation method is as follows: firstly add raw materials No. 2-7 into the stirring tank, disperse with a high-speed disperser for 30 minutes, then slowly add the PAH emulsion into the stirring tank, stir at 700 rpm for 60 minutes, and adjust the pH of the coating with ammonia water Value, when pH=8.0, filter the material, then add hydrophilic modified HDI curing agent to the filtered PAH emulsion, stir rapidly for 20 minutes, add water to dilute to the specified viscosity of 200cps, stand and filter, and the prepared water-based Two-component polyurethane coating with the following properties:

[0079] Appearance: milky white slightly transparent liquid, without mechanical impurities; pH=8.0; solid content 33%, viscosity 200cps.

[0080] Wood coating film performanc...

Embodiment 3

[0082] The monomer composition is butyl acrylate, methyl methacrylate, methacrylic acid and β-hydroxyethyl methacrylate, and the formula of acrylate hybrid emulsion is shown in Table 3:

[0083] table 3

[0084]

[0085] Add 0.75 parts of emulsifier, 0.2 parts of buffer, and 46.2 parts of deionized water into the reactor, raise the temperature to 75°C, stir for 30 minutes, and dropwise add 0.1 parts of methacrylic acid, 2 parts of butyl acrylate and 1 part of methacrylic acid Mixed monomers of methyl ester, add dropwise the aqueous solution (weight fraction is 5%) that contains 0.05 part of initiator (potassium persulfate) simultaneously, drop in half an hour, treat that emulsion is blue phase and stable 45 minutes, obtain seed emulsion, keep The temperature of the reaction system is 78°C, and then the first polar monomer mixture is added dropwise to the seed emulsion at a uniform speed to prepare polymer latex particles P 1 , the monomer mixture is composed of 10 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com