Manufacture method of biodegradable non-woven material

A non-woven material, biodegradable technology, used in non-woven fabrics, textiles and papermaking, melt spinning, etc., can solve the problems of easy molecular degradation, poor thermal stability of PLA, and high cost, and achieve good air permeability and soft hand feel. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

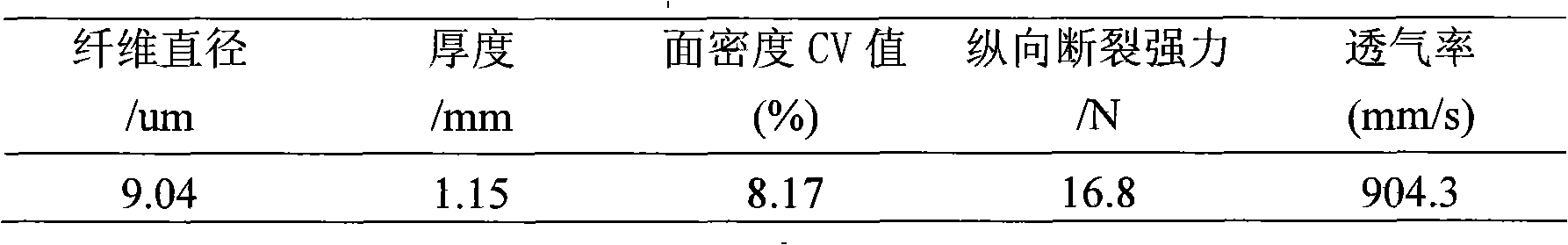

Embodiment 1

[0014] The method for making polysuccinate-co-butylene terephthalate (PBST) biodegradable nonwoven material of the present invention as described above mainly includes four processes of chip drying, melt extrusion, air drafting and fiber web reinforcement step. Each processing step adopts the following technological conditions:

[0015] Step 1: Dry polybutylene succinate-co-terephthalate slices at a starting temperature of 60°C, then increase the temperature to 100°C at a rate of 10°C / min, and dry at a constant temperature for 20 hours , to ensure that the moisture content of the slices is lower than 30ppm;

[0016] The second step: heat and melt the polymer chips in the screw extruder, and extrude them from the spinneret hole of the die head. The temperatures in zone four, zone five and zone six are 170, 230°C, 260°C, 260°C, 265°C, 265°C respectively, and the die head temperature is 260°C;

[0017] Step 3: When the melt is extruded from the spinneret hole of the die, the m...

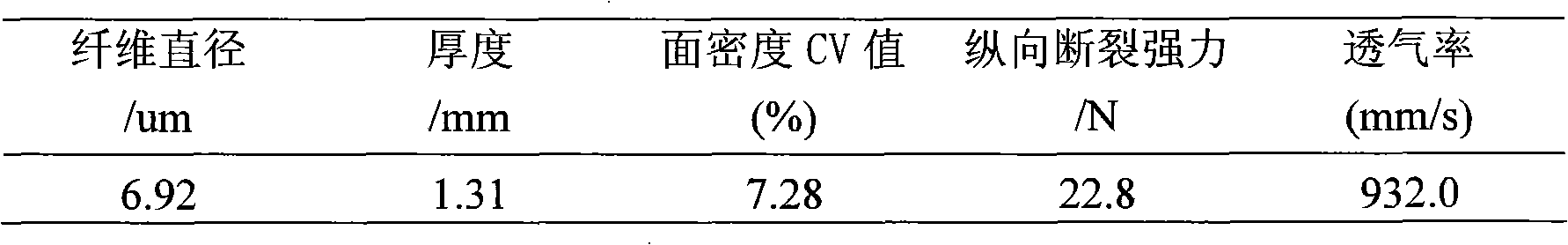

Embodiment 2

[0022] The method for making polysuccinate-co-butylene terephthalate (PBST) biodegradable nonwoven material of the present invention as described above mainly includes four processes of chip drying, melt extrusion, air drafting and fiber web reinforcement step. Each processing step adopts the following technological conditions:

[0023] Step 1: Dry polysuccinate-co-butylene terephthalate slices at a starting temperature of 60°C, then increase the temperature to 100°C at a rate of 10°C / min, and dry at a constant temperature for 24 hours , to ensure that the moisture content of the slices is lower than 30ppm;

[0024] The second step: the polymer chips are heated and melted in the screw extruder, and extruded from the spinneret hole of the die head, wherein the extrusion speed is 6.7rpm, and the first zone, the second zone, the third zone, The temperatures in Zone 4, Zone 5 and Zone 6 are 190°C, 270°C, 290°C, 290°C, 290°C, 290°C respectively, and the die head temperature is 29...

Embodiment 3

[0030] The method for making polysuccinate-co-butylene terephthalate (PBST) biodegradable nonwoven material of the present invention as described above mainly includes four processes of chip drying, melt extrusion, air drafting and fiber web reinforcement step. Each processing step adopts the following technological conditions:

[0031] Step 1: Dry polysuccinate-co-butylene terephthalate slices at a starting temperature of 60°C, then increase the temperature to 100°C at a rate of 10°C / min, and dry at a constant temperature for 22 hours , to ensure that the moisture content of the slices is lower than 30ppm;

[0032] The second step: heat and melt the polymer chips in the screw extruder, and extrude them from the spinneret hole of the die head. The temperatures in Zone 4, Zone 5 and Zone 6 are 175°C, 240°C, 280°C, 280°C, 285°C, 285°C respectively, and the die head temperature is 265°C;

[0033] Step 3: When the melt is extruded from the spinneret hole of the die, the melt is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com