Lithium battery packaging film with high barrier, acid resistance and alkali resistance

A technology of acid and alkali resistance, lithium battery, applied in acid and alkali resistance lithium battery packaging film, high barrier field, can solve the problems of poor insulation performance of molded flexible packaging film, leakage of electrolyte, decrease in barrier performance, etc., to achieve excellent heat sealing the effect of good strength and barrier properties, excellent elasticity and elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

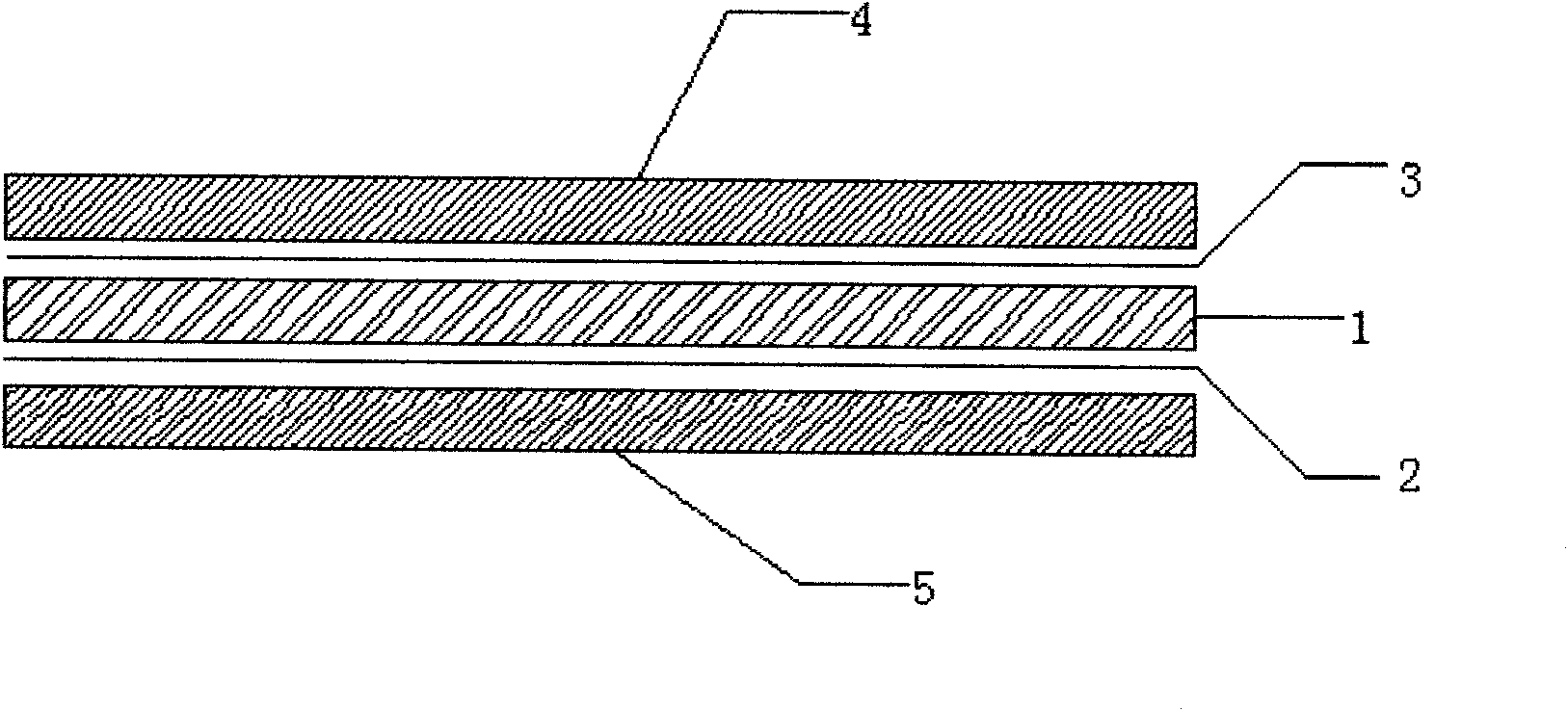

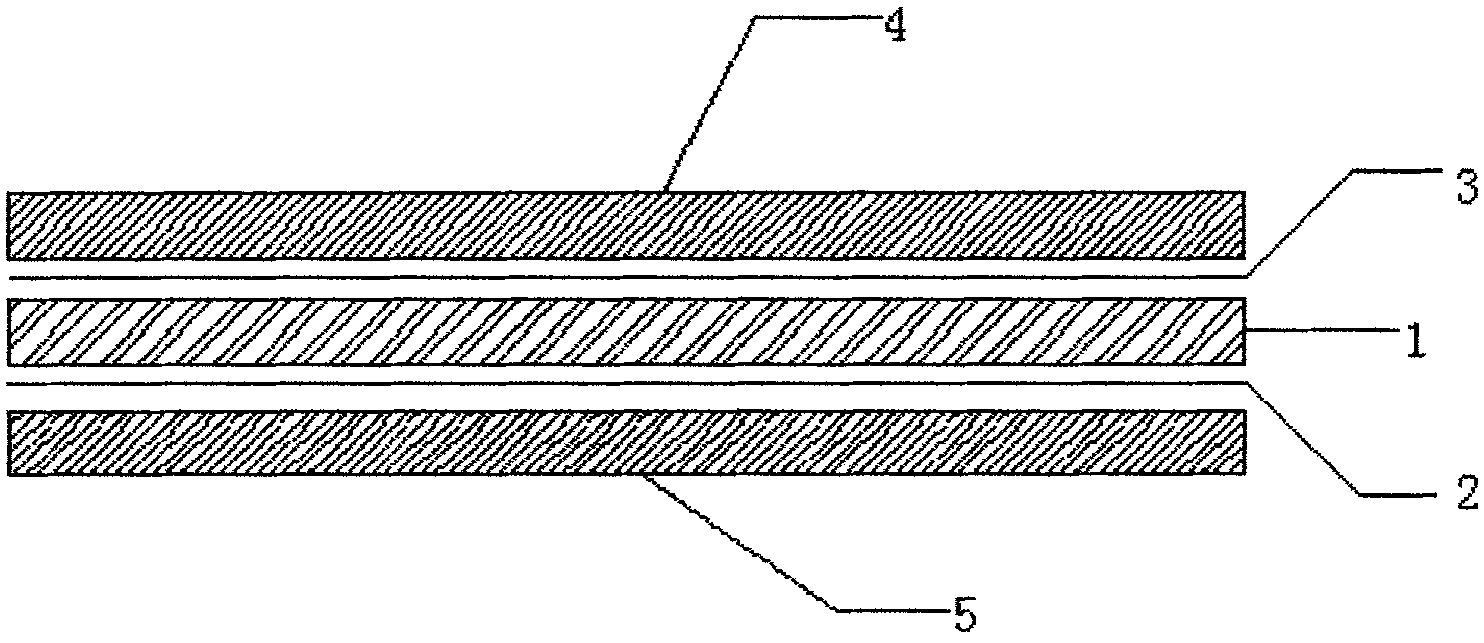

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a high-barrier, acid-alkali-resistant lithium battery packaging film uses a special aluminum alloy aluminum layer 1 as the middle base layer, and a high-strength nylon layer 4 is attached to the upper layer of the aluminum alloy aluminum layer 1. A layer of functional nano-silicon material 2 is plated between the aluminum alloy aluminum layer 1 and the nylon layer 4; a polypropylene layer 5 made of a nano-polymer material is attached to the lower layer of the aluminum alloy aluminum layer 1, and the A layer of functional nano-silicon material 3 is plated between the aluminum alloy aluminum layer 1 and the polypropylene layer 5 . The aluminum alloy aluminum layer 1 is plated with a layer of functional nano-silicon material 2, 3 after heat treatment by a special process, and the upper and lower layers are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com