Method for comprehensive utilization of iron and sulfur in tailing containing iron and sulfur

A technology for pyrite tailings and iron tailings, which is applied in the field of comprehensive utilization of iron and sulfur, can solve the problems of different iron-containing grades of sulfuric acid slag, low technical indicators, complex technologies, etc., and achieves great practicability, economic benefits, and technical indicators. High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

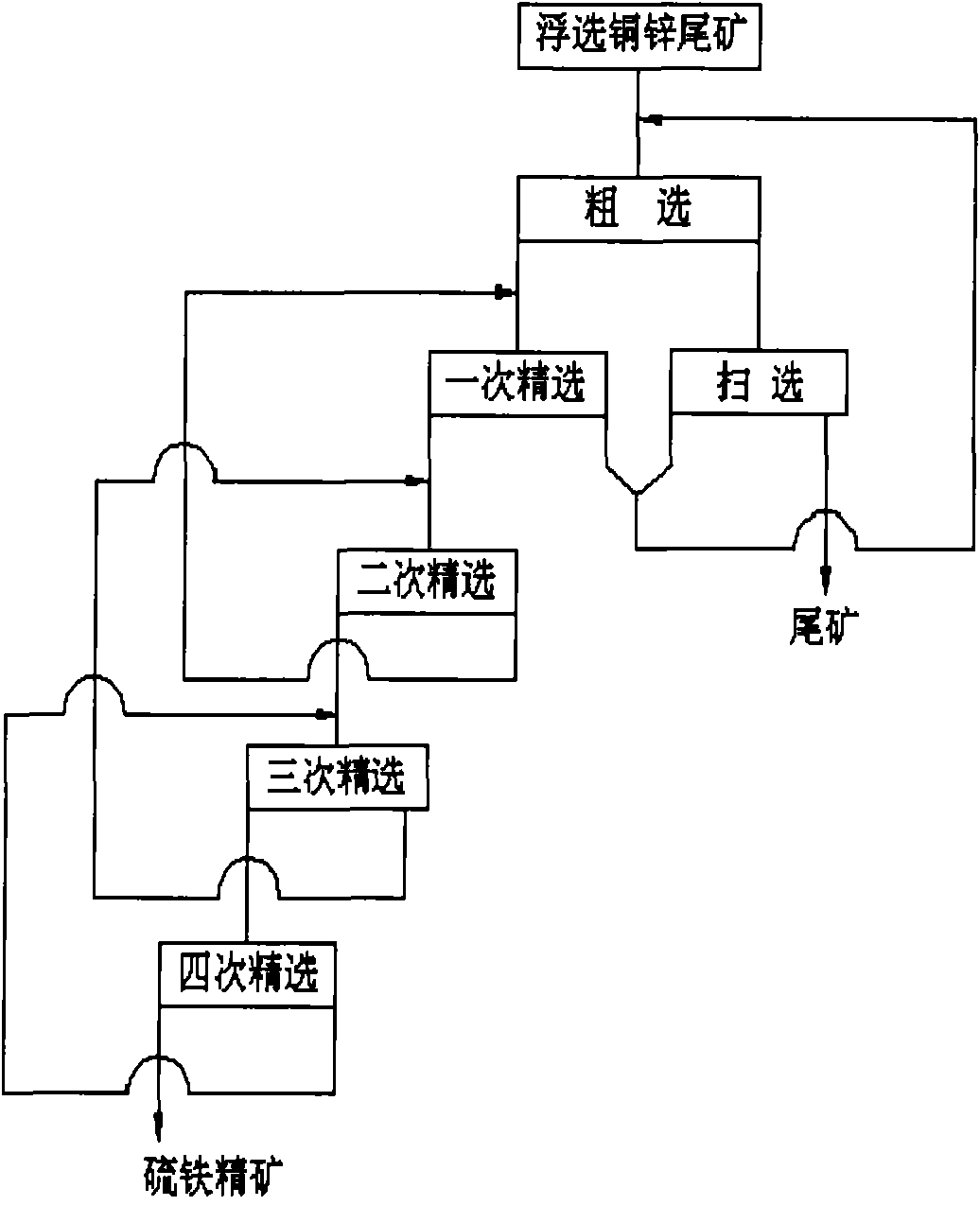

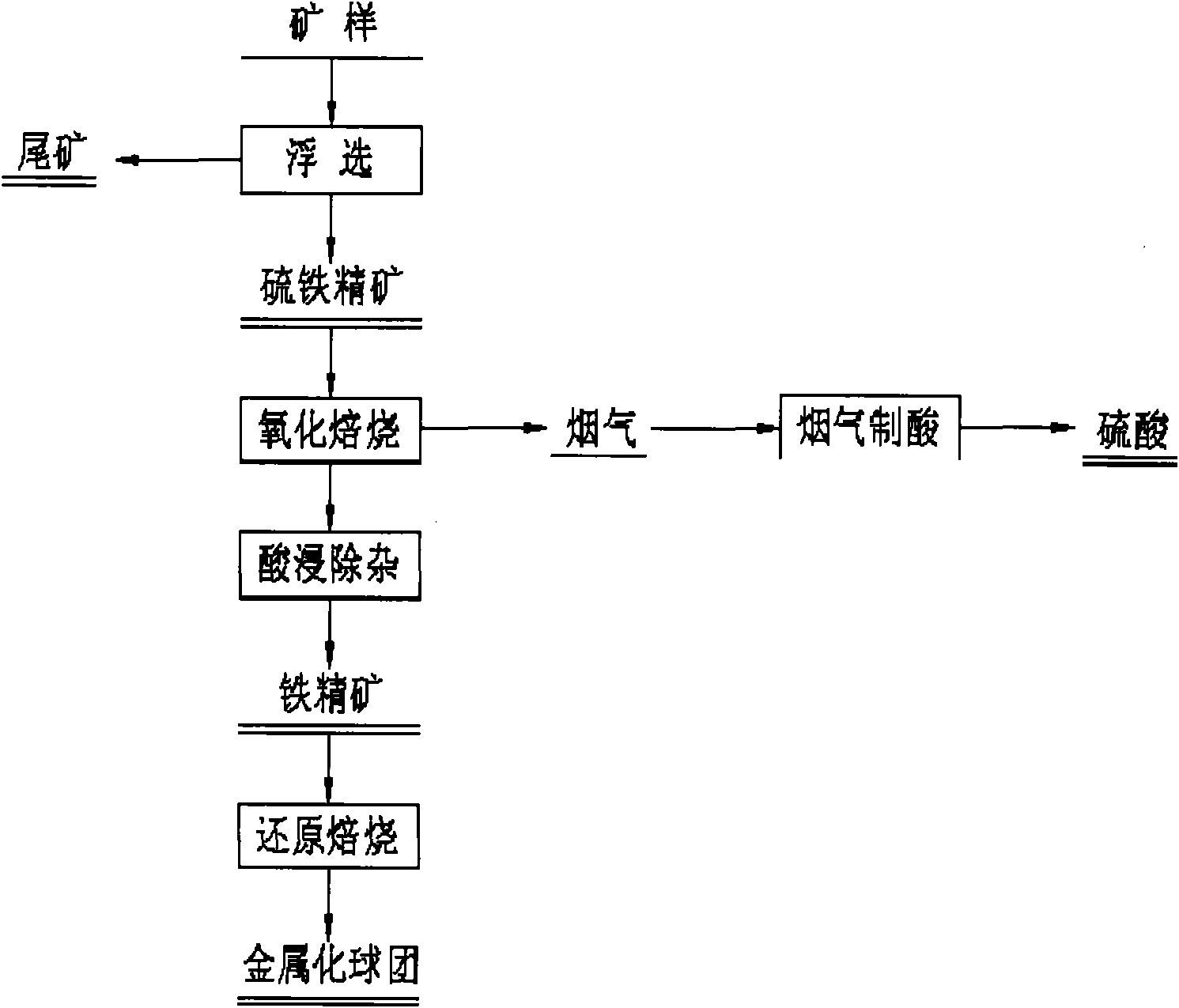

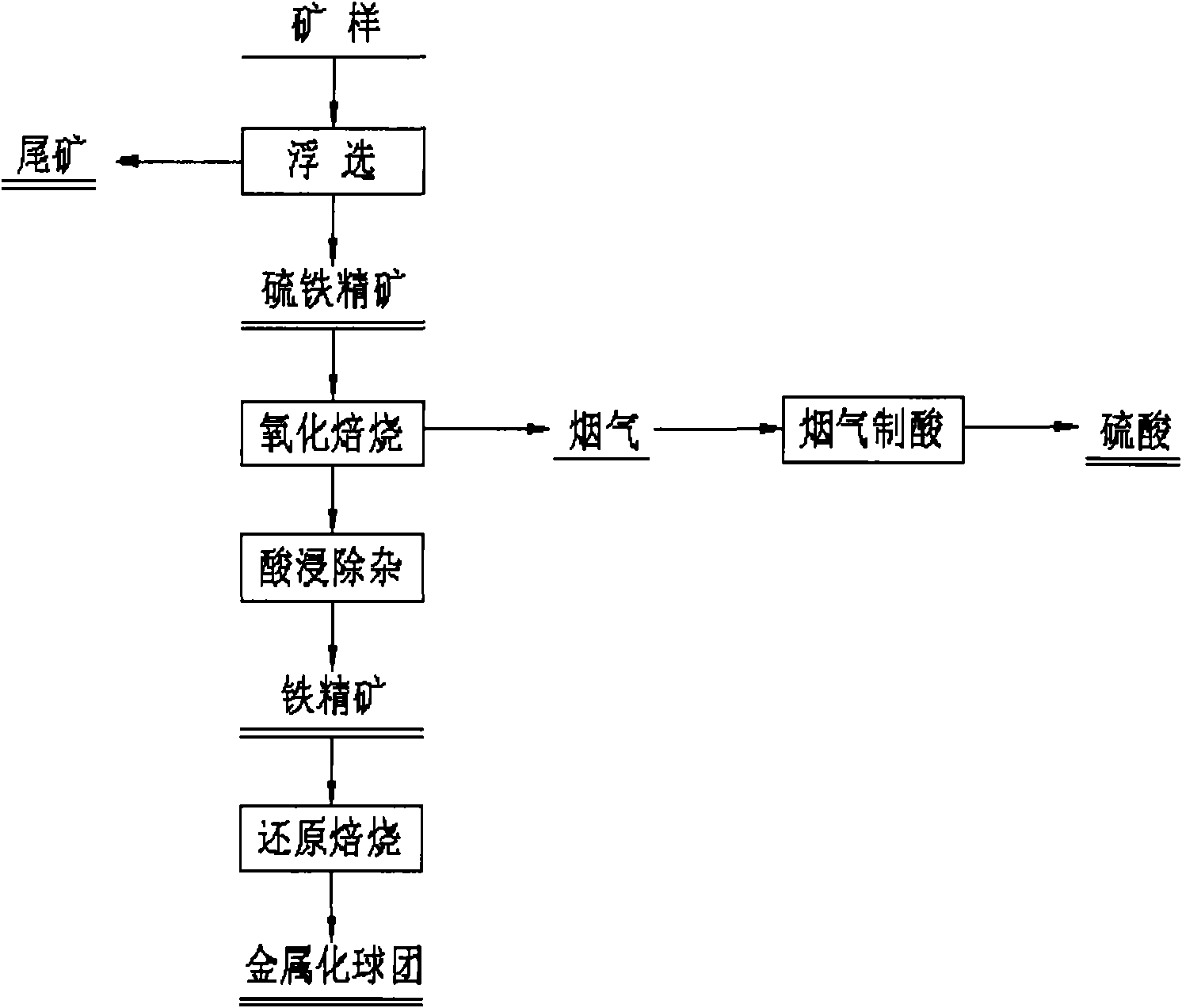

[0048] Such as figure 1 , figure 2 As shown in the figure, the pyrite tailings of copper and zinc flotation in a copper mine in Ashele are taken. The metal minerals in the ore are mainly pyrite, followed by chalcopyrite and sphalerite, and the gangue minerals are mainly quartz, clinoid Feldspar, mica, calcite, dolomite, chlorite, etc. The contents of iron, sulfur and copper in the ore are 27.98% iron, 29.02% sulfur and 0.18% copper respectively.

[0049] (1) rough selection

[0050] The pyrite tailings with a sulfur grade of 29% are prepared with water to form a pulp with a concentration of about 30% by weight and enter the roughing tank, adding sulfuric acid with a concentration of 20% by weight to keep the pH value of the pulp at 6; Add 1000 grams of sodium silicate to the tailings and stir well; then add 50 grams of butyl xanthate per ton of tailings and stir well; then add 60 grams of terpineol oil per ton of tailings and stir well; The foam layer in the tank is kept ...

Embodiment 2

[0066] Take pyrite tailings from copper and zinc flotation in a copper mine in Qinghai. The metal minerals in the ore are mainly pyrite, followed by magnetite and chalcopyrite. The gangue minerals are mainly calcite, dolomite and chlorite , quartz, etc. The contents of iron, sulfur and copper in the ore are 40.7% iron, 38.5% sulfur and 0.87% copper.

[0067] (1) rough selection

[0068] The pyrite tailings with a sulfur grade of 38.5% are prepared with water to make a slurry with a concentration of about 40% by weight and enter the roughing tank, and add sulfuric acid with a concentration of 10% by weight to keep the pH value of the slurry at 4.5; Add 1,000 grams of sodium hexametaphosphate to the tailings, and stir well; add 100 grams of butylamine black medicine to each ton of tailings, and stir well; then add 80 grams of No. 2 flotation oil to each ton of tailings, and stir well; Keep the foam layer in the flotation tank at a thickness of 5-50mm, and float for 10 minutes;...

Embodiment 3

[0080] The pyrite tailings of copper-zinc flotation in a copper mine in Qinghai are taken. The metal minerals in the ore are mainly pyrite, followed by chalcopyrite and sphalerite. The main gangue minerals are: quartz, plagioclase, mica, Calcite, dolomite, chlorite, etc. The contents of iron, sulfur and copper in the ore are 18.86% iron, 9.92% sulfur and 0.08% copper respectively.

[0081] (1) rough selection

[0082] The pyrite tailings with a sulfur grade of 9.92% are prepared with water to form a pulp with a concentration of about 20% by weight and enter the roughing tank, adding sulfuric acid with a concentration of 5% by weight to keep the pH value of the pulp at 8.5; Add 200 grams of sodium silicate to the tailings and stir well; add 20 grams of PAC to each ton of tailings and stir well; Flotation for 5 minutes at a thickness of 5-50 mm; the foam product is rougher pyrite concentrate, and the product in the tank is rougher tailings;

[0083] (2) Scanning

[0084] Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com